-

02-05 2026

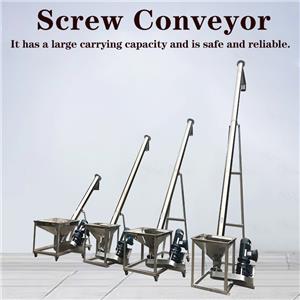

Today, we will introduce a stainless steel feeder

The material of the feeding machine is divided into A3 carbon steel, 201 stainless steel, and 304 stainless steel. 2. The feeding machine is suitable for conveying powders, granules, and sheet materials. 3. The conveying methods of the feeding machine include horizontal conveying, inclined conveying, and vertical conveying.

-

01-29 2026

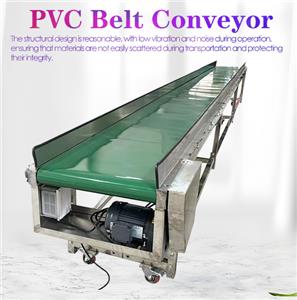

Today, we will introduce a production line conveying equipment

Conveyor belts are divided into PVC conveyor belts, PU conveyor belts, plastic chain plate conveyor belts, modular mesh conveyor belts, nylon conveyor belts, PTFE conveyor belts, and stainless steel conveyor belts according to their materials.

-

01-14 2026

Today, we will introduce a stainless steel feeding machine

Spiral conveyors are made of stainless steel and carbon steel, and the conveying methods are divided into horizontal, inclined, and vertical conveying.

-

12-11 2025

Today, let's talk about a high-efficiency conveyor belt conveyor

Belt conveyors are suitable for various scenarios due to their advantages of stable and efficient transportation, as well as simple operation. It can transport horizontally and obliquely, with flexible adjustment.

-

12-03 2025

Today, let's talk about what equipment is used for conveying granular powder

The stainless steel screw conveyor is composed of conveying pipes, blades, screws, motors, hoppers, and brackets. Suitable for conveying granular powders, flakes, and block materials in the food, chemical, agricultural, and daily chemical industries.

-

09-19 2025

Today, let's talk about the configuration issue of the screw conveyor

Spiral conveyors can be divided into parallel conveying, inclined conveying, and vertical conveying according to their structure. Suitable for conveying dry powder particles in food, chemical, daily chemical, agricultural and other industries.

-

09-15 2025

Today, let me introduce the functions of a belt conveyor

Belt conveyor, also known as conveyor belt, is a rubber fiber, metal composite product or plastic fabric composite product used in belt conveyors to carry and transport materials.

-

08-06 2025

Today, let's introduce the types of screw conveyors

The screw conveyor uses the rotation of the screw to push the material forward, generating a forward push between materials. The material is fed from the inlet and forcefully pushed to the outlet by the screw.

-

07-29 2025

Today we will talk about the vacuum powder suction machine

Vacuum powder suction machine is a device that uses vacuum suction to achieve closed conveying of powder materials, widely used in material handling processes in multiple industries.

-

07-17 2025

Today we will introduce the types of belt conveyors

There are various types of conveyor belts, which can be divided into parallel conveyor, uphill conveyor, and turning conveyor according to their conveying forms.