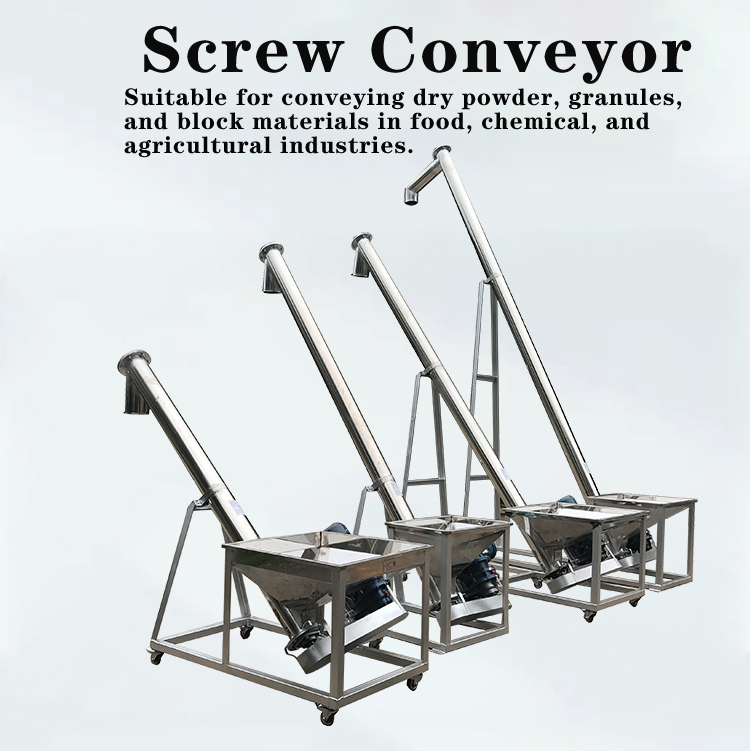

Today, let's talk about the configuration issue of the screw conveyor

Spiral feeding machine is suitable for conveying various powders, granules, sheet materials, etc. It is commonly used for conveying grains, cement, coal powder, urea, compound fertilizers, plastic granules, feed, etc. It is an essential equipment in food factories, chemical factories, plastic factories, building materials, agriculture, animal husbandry, packaging industries, etc.

The deceleration method of a screw conveyor: Simply put, the deceleration of a screw conveyor is achieved by using a specialized device to reduce the speed of the motor, allowing the spiral blades to rotate at an appropriate speed. This not only transports animal materials but also protects the equipment from damage. The common deceleration methods mainly include the following:

1. Gear reducer reduction

This is the most commonly used method, with the core consisting of a set of gears of different sizes. The motor drives the small gear to rotate, which in turn drives the large gear. The large gear rotates slower than the small gear, causing the speed to decrease. It is like the variable speed gear of a bicycle, stepping on it quickly (the motor is high-speed), and through gear matching, the wheels rotate slowly but more forcefully, which can adapt to the transportation of materials of different weights.

2. Worm gear reducer for deceleration

It consists of two components: a worm gear and a worm wheel. The motor drives the worm gear to rotate, which in turn drives the worm wheel. The deceleration effect of this method is very obvious, and it runs relatively smoothly and quietly. However, its efficiency in transmitting power is relatively low, making it more suitable for scenarios with small conveying volumes and low requirements for rotational speed, such as feeding small equipment.

3. Belt pulley deceleration

Deceleration is achieved through the combination of pulleys of different sizes and belts. The motor is connected to the small pulley, and the main shaft of the screw conveyor is connected to the large pulley, using a belt to connect the two. The small wheel rotates quickly, and by driving the large wheel slowly through the belt, the deceleration goal is achieved. This method has a simple structure and is easy to repair, but the belt may slip over time and requires regular inspection and adjustment.

4. Connect the coupling directly to the reduction motor

This method is to directly connect the "deceleration motor" with its own deceleration function to the main shaft of the screw conveyor through a coupling. The internal reduction design of the deceleration motor has been completed, without the need for additional reducers, which is equivalent to "one step in place". Its advantages are small size, small footprint, suitable for situations with limited space, and relatively direct power transmission.