Today, let's talk about what equipment is used for conveying granular powder

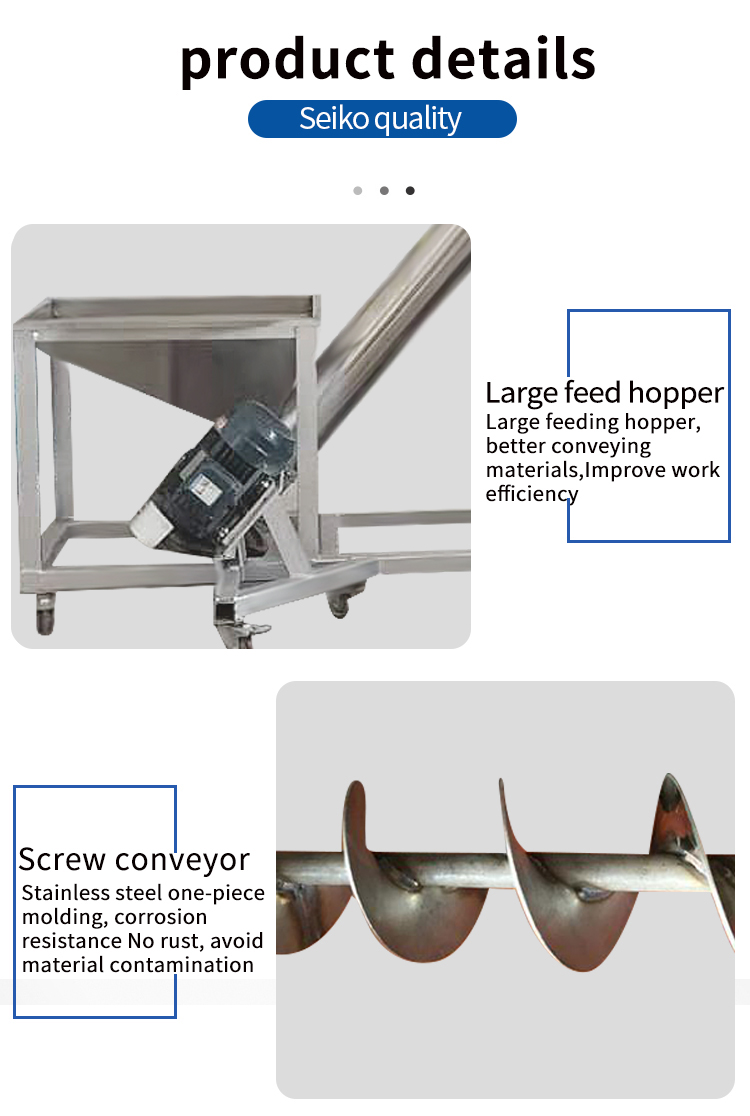

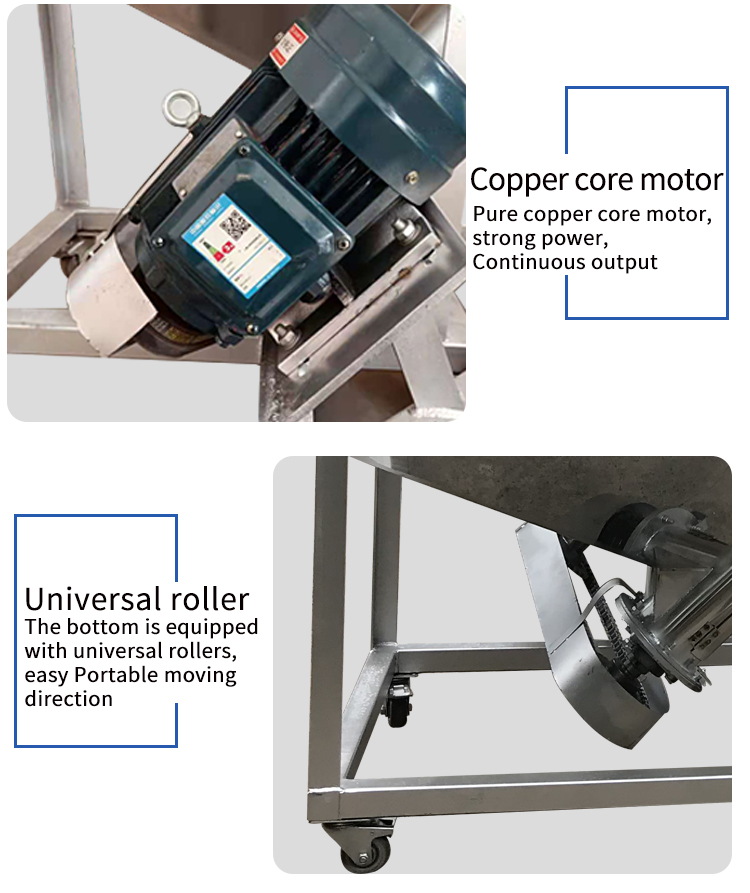

The screw conveyor is driven by a motor to rotate the spiral blades, and uses the friction and thrust between the blades and the material to transport the material from the inlet to the outlet. According to the installation angle, the most commonly used conveying methods include parallel conveying, inclined conveying, and vertical conveying.

Spiral feeding machine is suitable for conveying various powders, granules, sheet materials, etc. It is commonly used for conveying grains, cement, coal powder, urea, compound fertilizers, plastic granules, feed, etc. It is a necessary equipment in food factories, chemical factories, plastic factories, building materials, agriculture, animal husbandry, packaging industries, etc.

Spiral conveyor is a common material conveying equipment. By rotating the spiral blades, the gravity of the material and the frictional force generated by the pipe wall are pushed to move along a specific path, causing the material to move from one end to the other.

Spiral conveyor features:

1. It has a wide range of use and can be used to transport materials tilted, horizontal, or vertical upwards. It requires less space, has a large lifting angle, is easy to clean, and is easy to maintain.

2. Suitable for transportation in various environments, with characteristics such as acid, alkali, and salt water resistance. The entire machine has small size, high speed, accurate, fast, and uniform transportation speed.

3. The discharge end is equipped with a cleaning device, which has low noise and strong adaptability. The position of the inlet and outlet is flexible.

4. Different specifications of feeding machines can be customized according to customer needs, such as hopper size, conveying height, motor position, etc. The screw conveyor has a compact overall size and is easy to maintain.

Maintenance and upkeep of screw conveyor:

Before starting the screw conveyor, first check whether the power supply is normal, ensure that the motor power line is connected correctly, and the supply voltage is normal. Check the daily operation duty records to confirm that there are no abnormalities in the equipment.

2. Regularly inspect the electrical wiring of the equipment to ensure smooth operation and no abnormal noise.

3. Check the electrical wiring and operation status of the equipment every week to ensure smooth operation and no abnormal noise.

4. Regularly replace lubricating oil to maintain good lubrication status of all components of the equipment.

5. Regularly check the oil level and color of the gearbox, and add or replace lubricating oil if necessary.