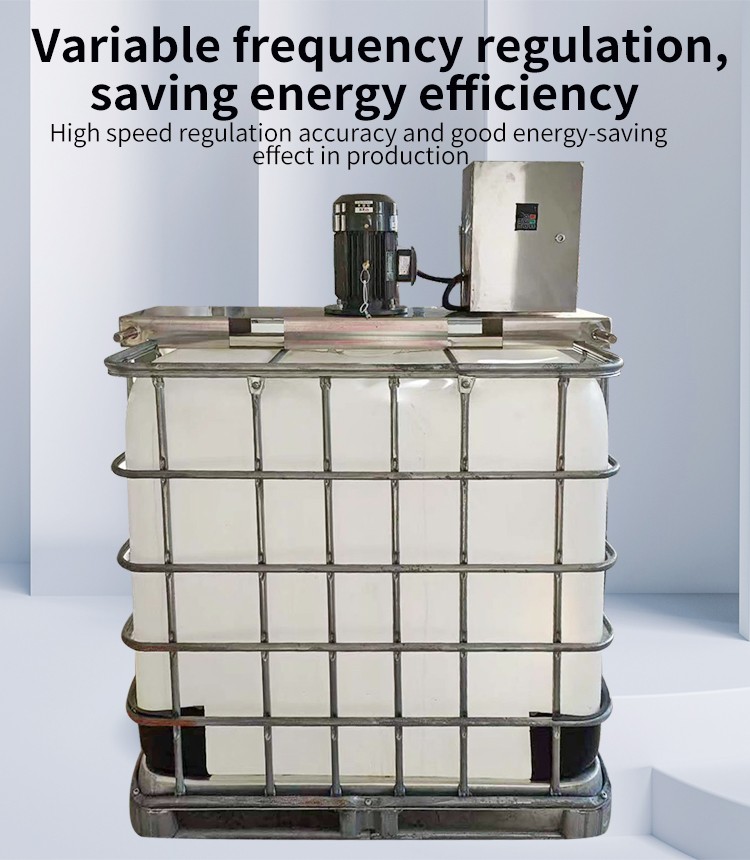

Today, let's introduce the function of IBC mixer

The core of the lifting IBC ton bucket mixer is to adjust the height of the mixing components through the lifting mechanism, adapt to different bucket depths, and achieve direct mixing of materials in the ton bucket without transferring or unloading. It is suitable for mixing liquid, paste, and solid-liquid mixed materials in industries such as chemical, food, and building materials, and has the advantages of high efficiency, energy saving, convenience, and strong adaptability, greatly improving the efficiency and uniformity of batch material mixing.

1. Strong adaptability: Accurately matched with standard IBC drums, can be directly mixed with drums, compatible with multiple specifications of drums, suitable for solid-liquid and liquid-liquid mixing scenarios, covering material needs from multiple industries.

2. Efficient and energy-saving: The mixing component penetrates deep into the barrel to reach the material layer, with no dead corners and high mixing uniformity (uniformity ≥ 98%). The batch mixing efficiency is increased by more than 30% compared to traditional mixing equipment. The motor is designed with energy-saving features and low energy consumption.

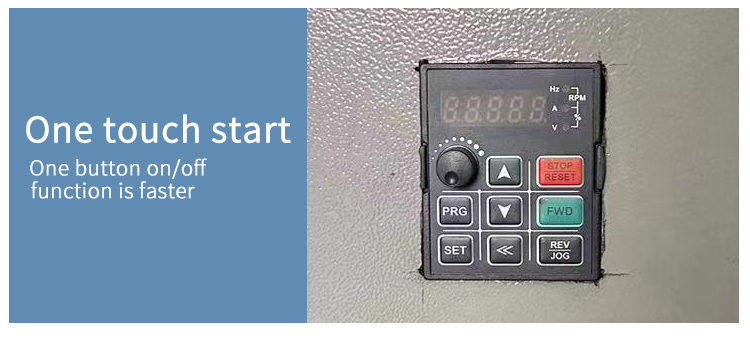

3. Convenient operation: electric/hydraulic lifting, one click height adjustment, quick docking, easy loading and unloading of barrels, single person operation; The control system is simple, the speed is adjustable, and it is suitable for different mixing processes.

4. Safety and stability: The bracket is stable, the positioning of the ton bucket is firm, and there is no shaking during mixing; The motor is equipped with overload protection, the lifting mechanism is equipped with anti fall locking, and some models are made of stainless steel material, with corrosion-resistant and explosion-proof design, suitable for chemical corrosive materials and explosion-proof scenarios.

5. Cost saving: No need to transfer materials, reducing unloading losses and pollution, and lowering labor costs; The equipment can be repeatedly adapted for ton bucket use without the need for customized specialized mixing containers, resulting in low maintenance costs.

Technical features of IBC ton drum mixer:

1. The copper-core motor is equipped with a reducer, with large torque and strong power.

2. The part in contact with the liquid is made of SUS304 stainless steel, with good acid and alkali corrosion resistance.

3. The mixing shaft and paddle are fixed with screws for easy disassembly.

4. The horizontal plate is equipped with a forklift extraction hole position to facilitate forklift operation

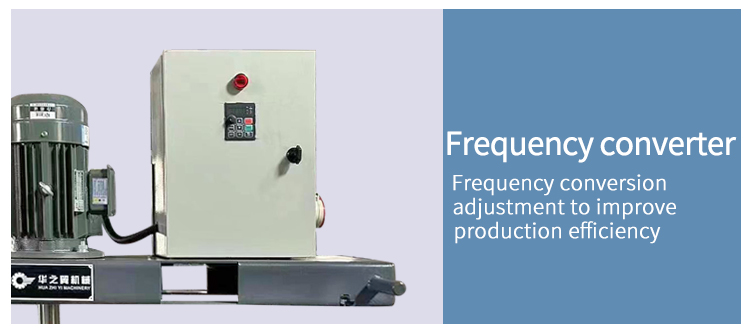

5. The mixer is equipped with variable frequency speed control, and the speed can be adjusted according to the demand.