Today we will introduce the types of belt conveyors

A belt conveyor is a continuous running transportation equipment that uses a conveyor belt as the traction and load-bearing component, and the frictional resistance between the tensioned conveyor belt and the transmission drum as the traction force.

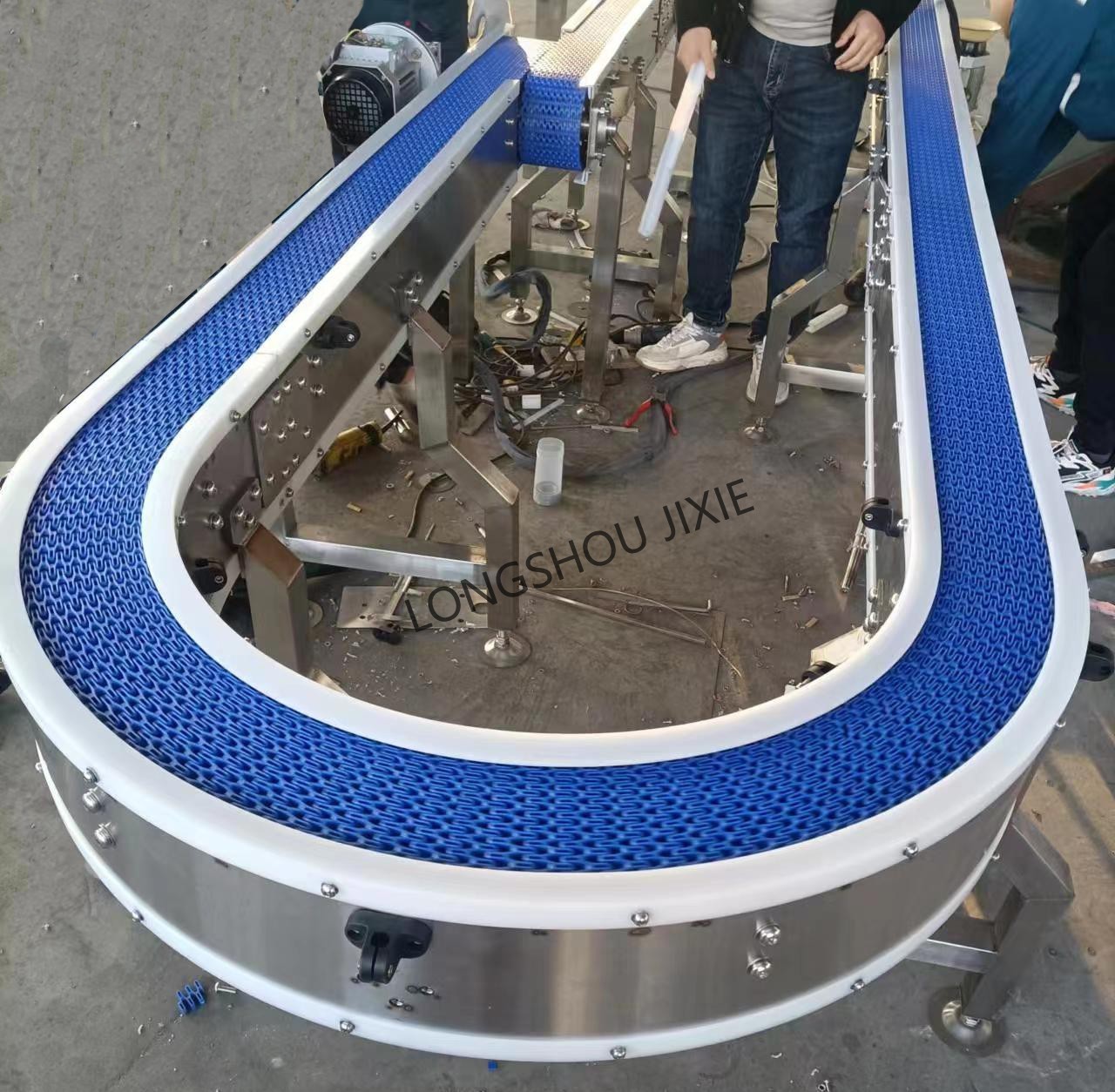

The conveyor belt is wound around the drive roller and the tail roller to form an endless loop belt, supported by rollers to limit deflection and sag, and the tensioning device provides the required tension for the conveyor belt. During operation, the electric motor drives the transmission drum through a reducer, relying on the frictional force between the transmission drum and the conveyor belt to continuously move the conveyor belt. The transported items are transported to the unloading location by the frictional force between the transmission drum and the conveyor belt.

Classified by conveying inclination angle:

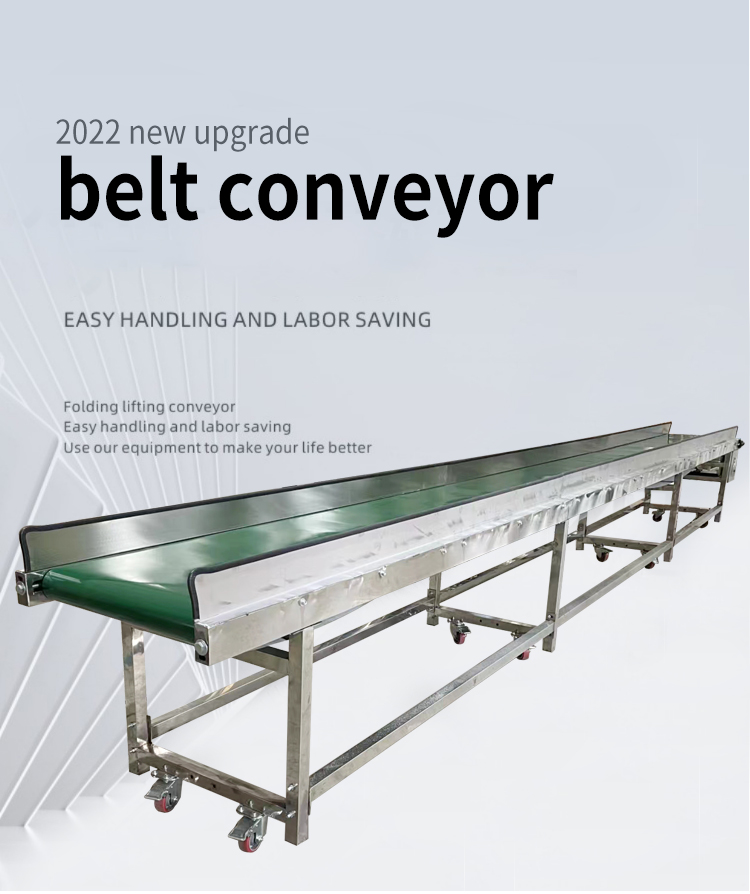

Horizontal belt conveyor: The conveyor belt is in a horizontal state and is mainly used for material transportation in the horizontal direction, such as material transfer between different processes in the workshop.

Tilted belt conveyor: The conveyor belt is inclined at a certain angle to the horizontal plane, which can realize the up and down transportation of materials. The inclination angle is determined according to the characteristics of the material and the type of conveyor belt, and is commonly used for the inflow and outflow of materials in warehouses and silos.

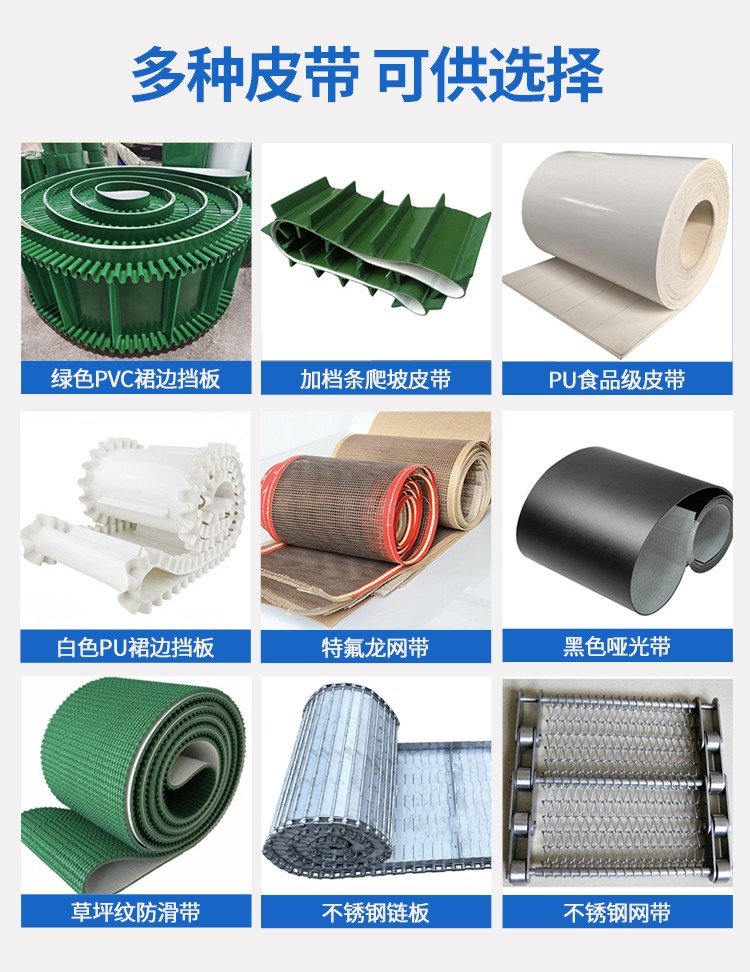

Classified by conveyor belt material:

Rubber belt conveyor: The conveyor belt is made of rubber material, which has good elasticity and wear resistance, and is suitable for conveying most bulk materials and finished items.

Steel belt conveyor: The conveyor belt is made of metal steel strip, which is resistant to high temperatures and has high strength. It is suitable for conveying high-temperature and heavy-duty materials, such as high-temperature billets in the metallurgical industry.

Plastic belt conveyor: The conveyor belt is made of plastic material, which is lightweight and corrosion-resistant. It is commonly used in industries with high hygiene requirements such as food and medicine.

There is no fixed standard for the conveying speed of a belt conveyor, which is mainly determined based on factors such as the characteristics of the conveyed material, the conveying volume, and the purpose of the equipment. The selection of conveying speed needs to balance efficiency and safety, ensure stable material conveying, and meet production process requirements.