Today we will talk about the vacuum powder suction machine

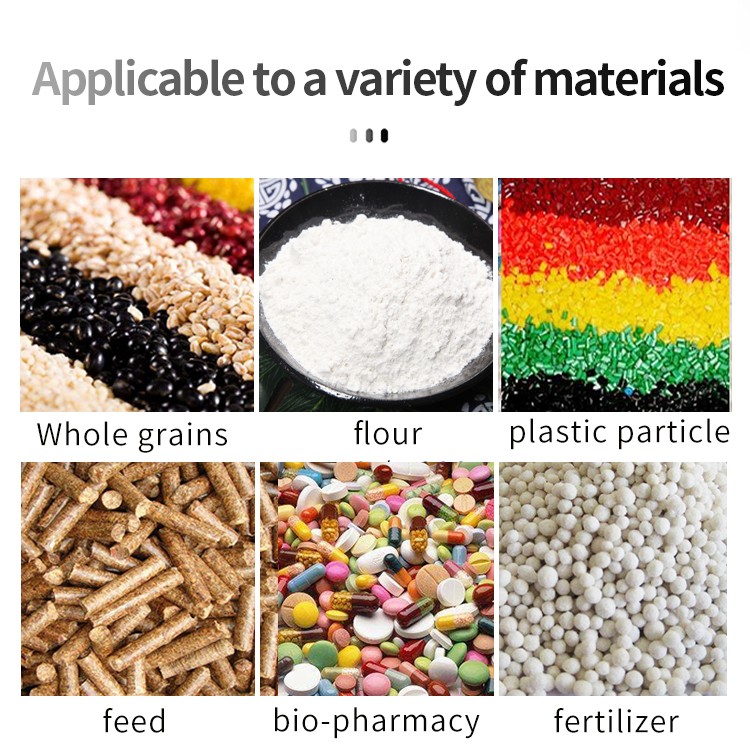

application area :

In the field of chemical engineering, it is used to extract various chemical raw material powders, such as

plastic powder, coating powder, activated carbon powder, alumina, etc.

Food processing: It can absorb milk powder, starch, flour, cocoa powder, seasoning powder, etc., and

transport the raw materials to processing equipment or packaging workshops.

Other industries: It is also widely used in lithium battery new energy, metal powder, building materials

and other industries, such as conveying lithium cobalt oxide, ternary materials, cobalt powder, tungsten

powder, cellulose ether powder, etc.

Structure composition of vacuum powder suction machine:

1.Vacuum pump: Provides vacuum suction, common ones include vortex air pump, Roots blower, etc.

2.Suction component: including stainless steel suction nozzle, conveying hose, etc., used for suction

and conveying powder.

3.Filtering device: such as PE filter, 316L stainless steel filter, etc., to prevent dust from entering the

vacuum pump and external environment.

4.Control components: such as electric control box, automatic material level control device, etc., to

achieve automatic control of the powder suction machine.

5.Discharge device: such as pneumatic discharge door device, discharge butterfly valve, etc., to control

the discharge of materials.

Characteristics of vacuum feeding machine products:

1.Environmentally friendly and clean: Closed conveying, no dust leakage, no cross contamination, effectively preventing dust from flying and improving the working environment.

2.Compliant with standards: Compliant with GMP standards, meets CIP requirements, can provide sterile grade products, suitable for industries with high hygiene requirements.

3.Reasonable design: Modular design, eliminating dead corners, quick and convenient disassembly, cleaning.

4.Versatile functions: It can effectively solve the stratification phenomenon of powder particles, eliminate material static electricity, generate no heat during the working process, and is safe and explosion-proof.

5.Easy to operate: automatic control, simple and convenient operation, no vibration, low noise, high efficiency and energy saving, low operation and maintenance costs.