Today, let's talk about how to choose a stainless steel crusher

Crushers are widely used in various industries such as food and chemical, for crushing small, segmented, and granular materials with low to medium hardness. The fineness of crushing can be freely adjusted between 20-120 mesh according to the sieve and production requirements.

Crushers are widely used in various industries such as food and chemical, for crushing small, segmented, and granular materials with low to medium hardness. The fineness of crushing can be freely adjusted between 20-120 mesh according to the sieve and production requirements.

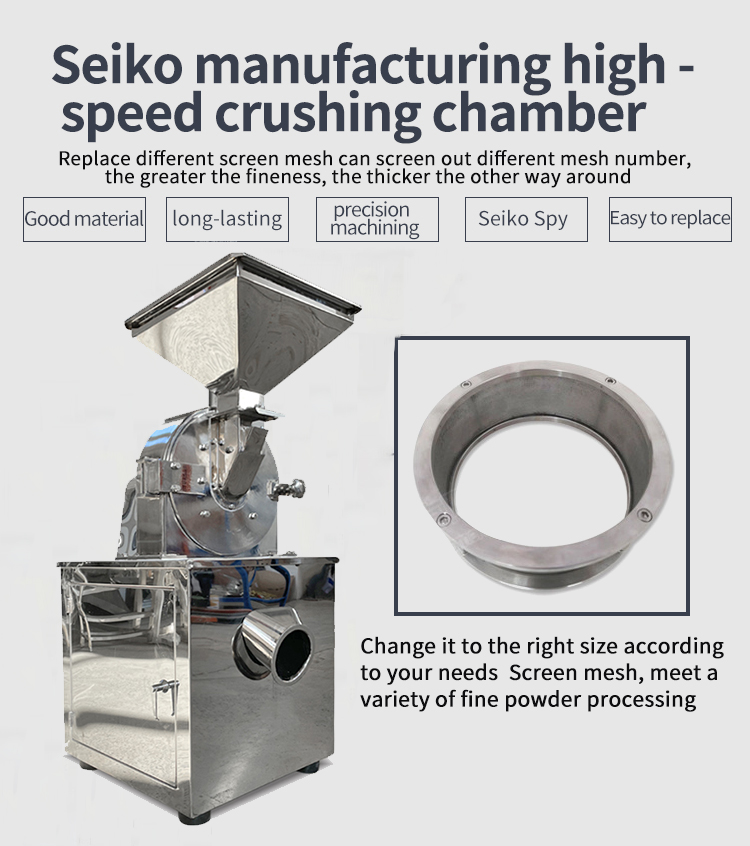

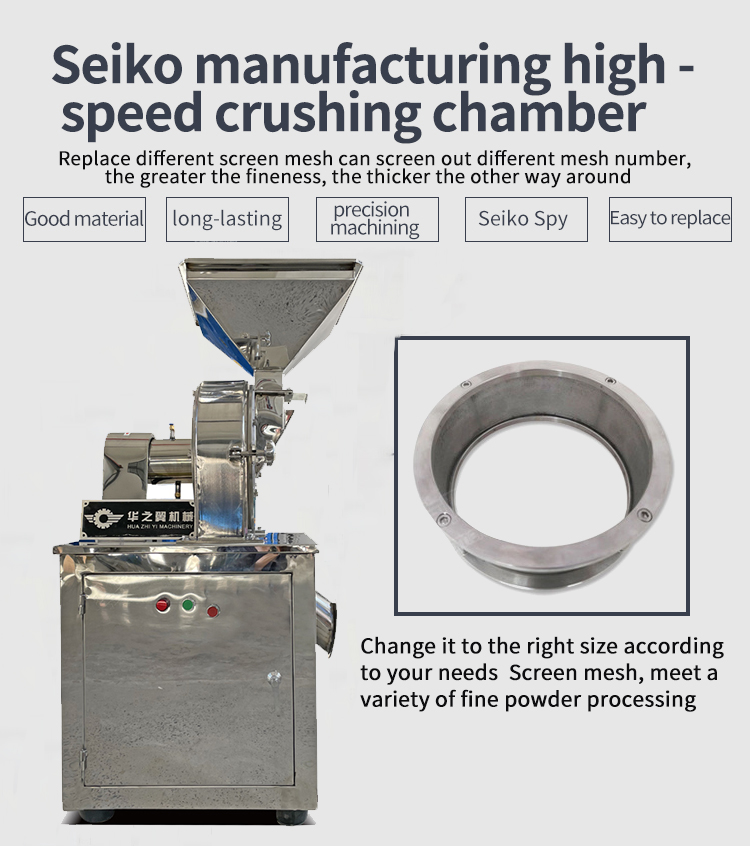

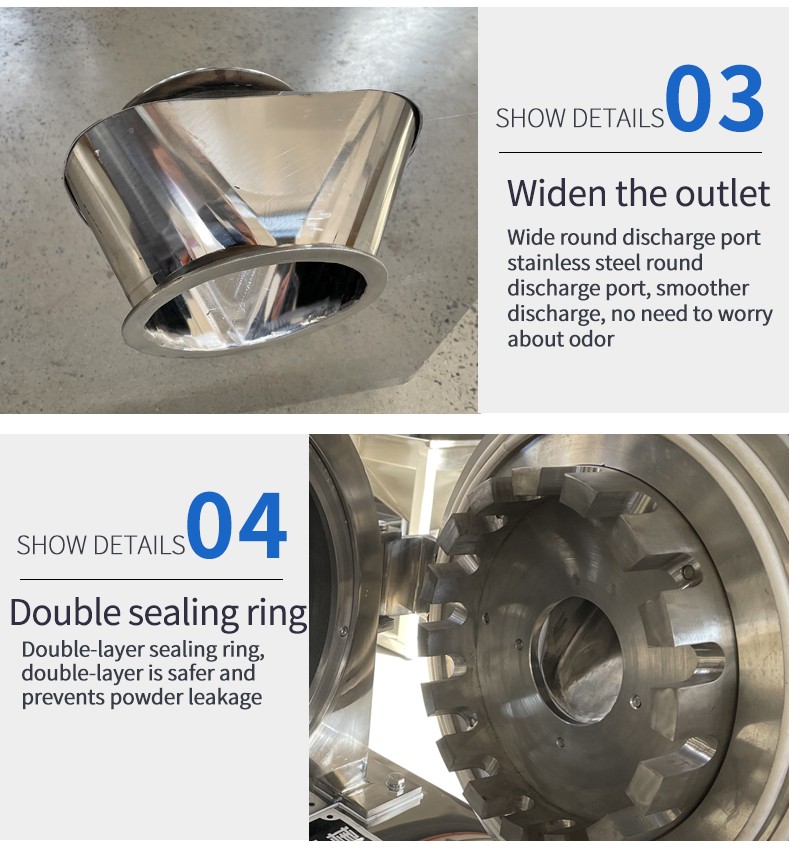

The universal crusher has a simple and sturdy structure, smooth operation, and excellent crushing effect. The crushed material can be directly discharged from the main grinding chamber, and the particle size can be obtained by replacing different mesh screens with different aperture sizes.

The working principle of the crusher utilizes the height between the movable toothed disc and the fixed toothed disc The relative motion of speed enables the crushed material to be crushed through a combination of gear impact, friction, and material impact with each other. The crushed material can be directly discharged from the main grinding chamber, and the particle size can be obtained by changing the sieve mesh with different aperture sizes.

Instructions for using the crusher:

1. Before starting up, it is necessary to check whether the door is tightly closed. When closing the door, tighten the handwheel and positioning bolts.

2. Connect the water cooling device to ensure sufficient water supply, and it is strictly prohibited to cut off water during operation.

3. When installing, turn on the power and electrically check whether the motor rotates in the direction indicated by the arrow. If it is the opposite, please adjust the wiring of the motor junction box.

4. With the motor rotating in the correct direction, start and idle for 30 minutes, check the lubrication condition, and add lubricating grease in a timely manner. Regularly inspect and replenish lubricating grease.

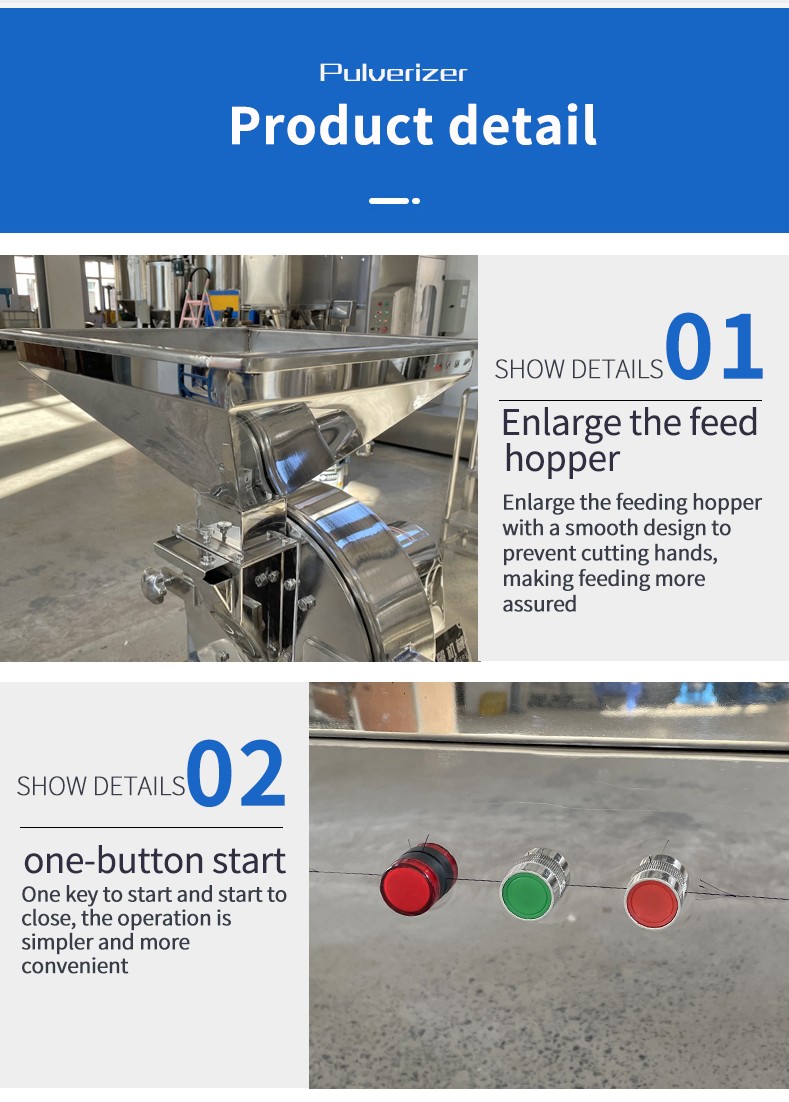

5. Before feeding, air rotate for a few minutes, then slowly and evenly add the material. Do not fill the hopper completely, and pay attention to whether the current is overloaded to prevent damage to the equipment.

6. If there is any significant vibration or noise during operation, it should be promptly shut down for inspection.

7. Regularly maintain lubrication and cleanliness of machinery, and promptly repair or replace any faults or defects found.

Characteristics of crusher:

1. This machine is made of all stainless steel and meets GMP requirements.

2. The structure is simple, the crushing chamber is easy to assemble and disassemble, and easy to clean.

3. Smooth operation, low noise, and minimal vibration.

4. Easy to operate. Replacing the sieve can control the fineness of the powder.