Today, let's introduce the types of screw conveyors

Spiral feeding machine is suitable for conveying various powders, granules, sheet materials, etc. It is commonly used for conveying grains, cement, coal powder, urea, compound fertilizers, plastic granules, feed, etc. It is an essential equipment in food factories, chemical factories, plastic factories, building materials, agriculture, animal husbandry, packaging industries, etc.

Spiral conveyors can be divided into the following categories according to their conveying methods:

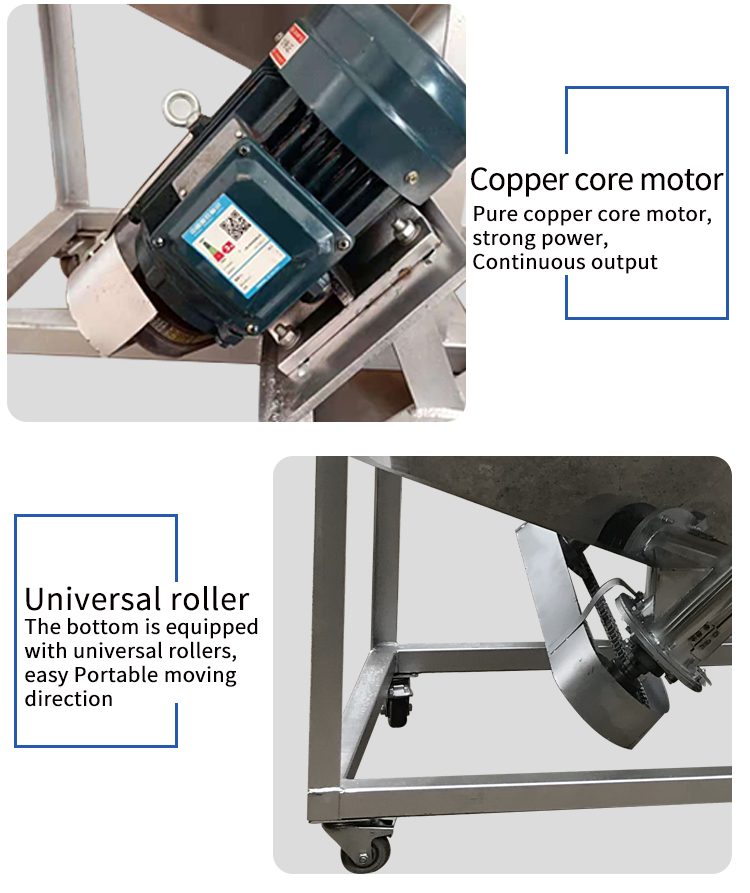

Horizontal screw conveyor: Material is transported horizontally and is the most common type, suitable for short distance, horizontal range material transfer, such as material transfer between different equipment in the workshop.

Tilted screw conveyor: The material is conveyed in an inclined direction, with a tilt angle usually not exceeding 30 ° (excessive angles can affect conveying efficiency and cause material slippage). It is commonly used to transport materials from low to high places, such as from the ground to storage bins.

Vertical screw conveyor: Materials are transported in the vertical direction and pushed upwards by the rotation of the spiral blades. It is suitable for scenarios where space is limited and materials need to be vertically lifted, such as transporting from underground material pits to surface equipment. Its structure requires special design to overcome material gravity and prevent sliding.

Spiral conveyors can be classified into the following categories based on their materials:

-Carbon steel material: Low cost, high strength, good processing performance, suitable for conveying general materials that are non corrosive and do not require high hygiene, such as cement, coal, stone, etc. But it is prone to rusting in damp or corrosive environments.

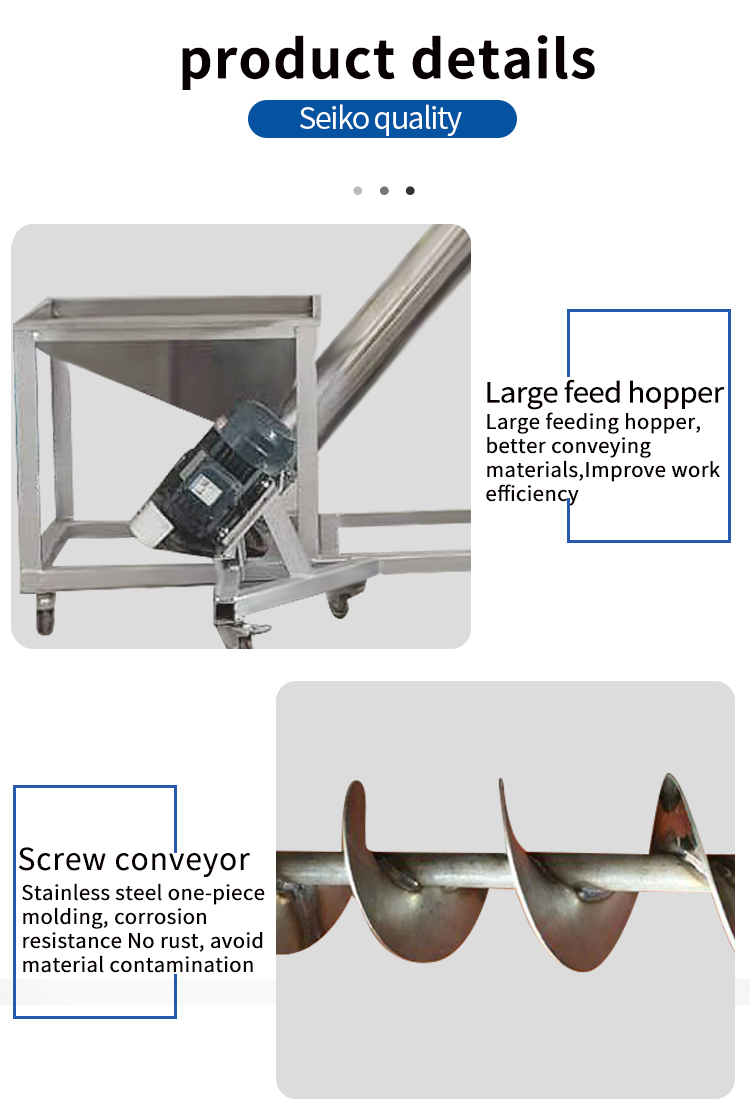

-Stainless steel material: It has the characteristics of corrosion resistance, high temperature resistance, rust prevention, and good hygiene performance. It has a high surface finish and is easy to clean and disinfect. It is suitable for conveying materials with high hygiene requirements or corrosive properties in food, chemical, and other industries. Common models include 201, 304, 316, 316L, etc.

Classified by external structure

-U-shaped screw conveyor: The screw shaft rotates in the U-shaped groove, which makes it easier to observe the material conveying situation compared to the tubular structure. The bottom of the U-shaped groove is convenient for installing cleaning devices and can be used horizontally or obliquely, suitable for small inclination angles and small range conveying.

-Pipe type spiral conveyor: The spiral blades are installed in a closed circular pipeline, which is a continuous cylinder. The inlet and outlet are usually connected to the pipeline through flanges or openings, with excellent sealing performance, which can effectively prevent dust from flying and material leakage.