Today we will talk about steam heating tanks

The steam heating mixing tank has high heating efficiency, strong temperature controllability, and can achieve uniform mixing, making it suitable for industries such as food, chemical, daily chemical, and agriculture.

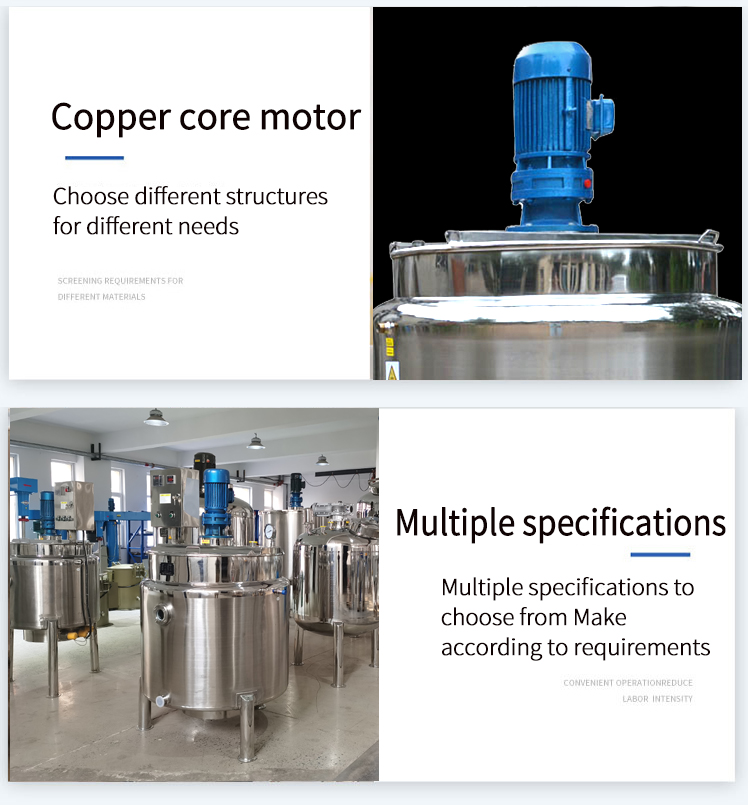

The steam heated mixing tank achieves efficient processing of materials through the dual effects of steam heating and mechanical stirring. Steam enters the mixing tank through a jacket or internal pipeline, directly heating the material. The temperature and pressure of steam can be adjusted to meet the heating needs of different materials. The tank is equipped with a stirrer (such as paddle type, screw type, etc.) to evenly mix the materials by rotating, preventing local overheating or clumping.

Characteristics of mixing tank:

1: Suitable for stirring, color mixing, blending, and homogenization of powders and liquids, or liquids and liquids;

2: Design the structure and configuration according to the customer's production process requirements; More standardized and humanized;

3: During the mixing process, feeding control, discharging control, mixing control, and other manual and automatic controls can be achieved;

4: It can be purchased separately or as a set according to the actual situation of the customer;

Electric heating mixing tank, heating methods include: thermal oil thermal conduction, hot water circulation heating, coil steam heating; The device has a reasonable structural design, a large heating area, uniform heating, and adjustable heating temperature. For electric heating type mixing tanks, the company has strict requirements for heating sealing and meticulous workmanship.

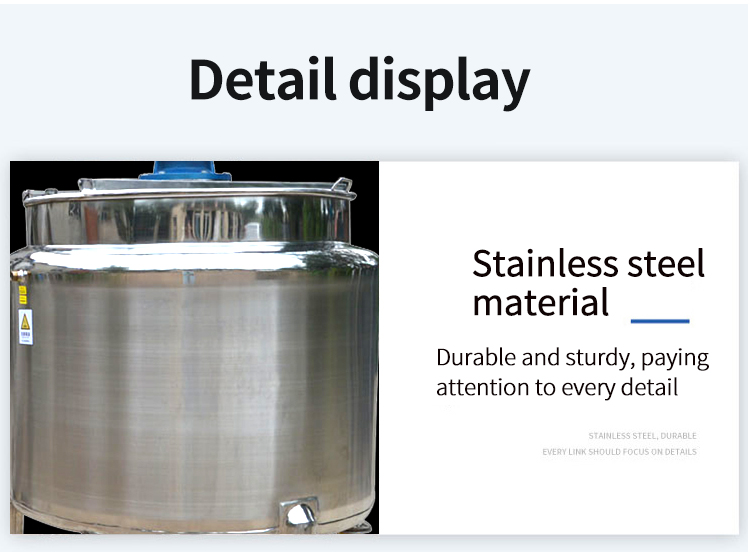

The stainless steel mixing tank is tailor-made according to customer requirements. To briefly introduce, it consists of a stainless steel tank body, stainless steel upper cover, mixer, support, transmission device, shaft seal device, etc. The mixing tank body and cover can be connected by welding or by flange sealing; We can provide process pipe holes such as inlet, outlet, sight glass, temperature measurement, liquid level measurement, pressure measurement, steam distillation, and vent valve according to customer requirements. The cycloidal pin reducer is driven by an electric motor, and then the agitator inside the mixing tank is driven by a transmission shaft to thoroughly mix the materials; Various forms such as atmospheric pressure flat cover, mechanical seal, and labyrinth seal can be processed according to requirements. Due to the different production processes of users, the agitator forms include frame type, anchor type, blade type, spiral type, high-speed dispersing disc, high shear emulsification type, etc.