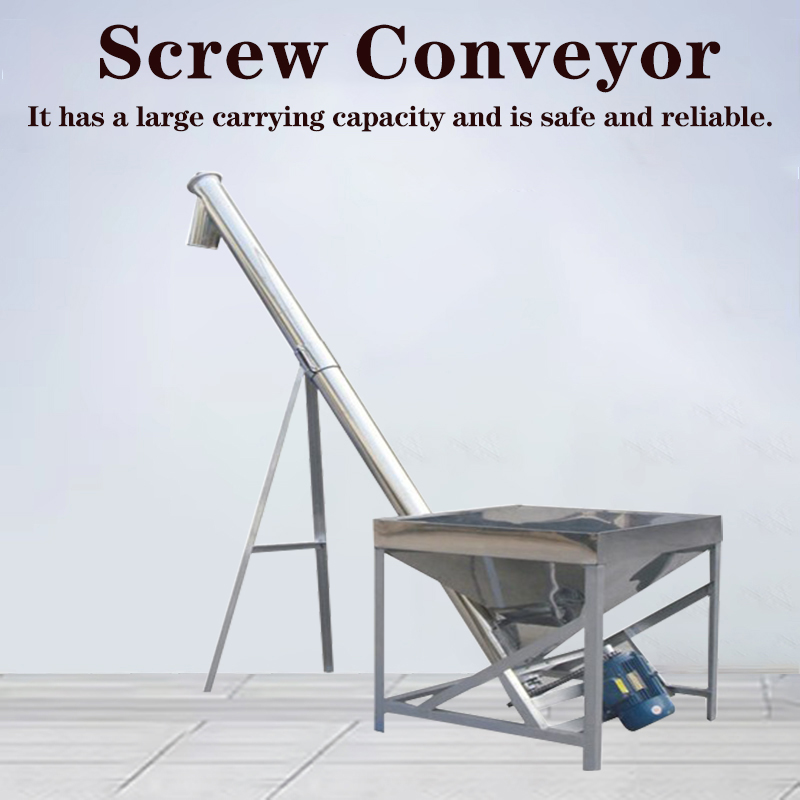

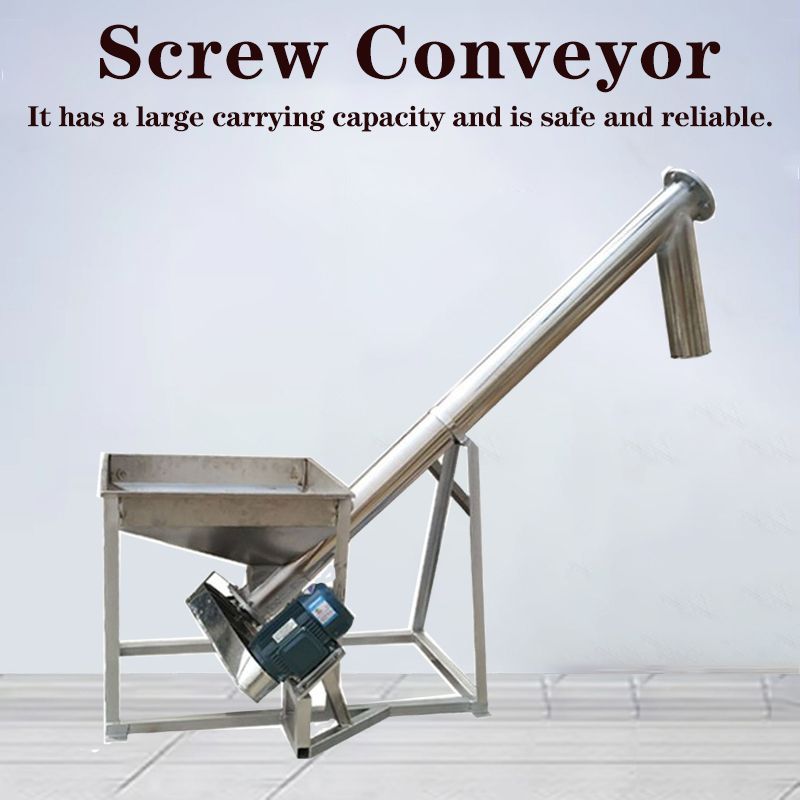

Today, we will introduce a stainless steel feeder

Spiral feeder is suitable for conveying powdered, granular, and block materials in industries such as food, chemical, plastic, feed, and construction. Made of carbon steel or stainless steel material. It can be moved freely, and the conveying method can be horizontal, inclined, vertical, etc.

Stainless steel screw conveyor refers to a conveying equipment made of stainless steel material, also known as screw feeder, screw packing machine, screw feeding machine, etc. It is a device that transports materials from low to high, saving labor, reducing material spillage, minimizing losses and waste, and is easy to operate and convenient.

Introduction to Spiral Feeding Machine:

1. The material of the feeding machine is divided into A3 carbon steel, 201 stainless steel, and 304 stainless steel.

2. The feeding machine is suitable for conveying powders, granules, and sheet materials.

3. The conveying methods of the feeding machine include horizontal conveying, inclined conveying, and vertical conveying.

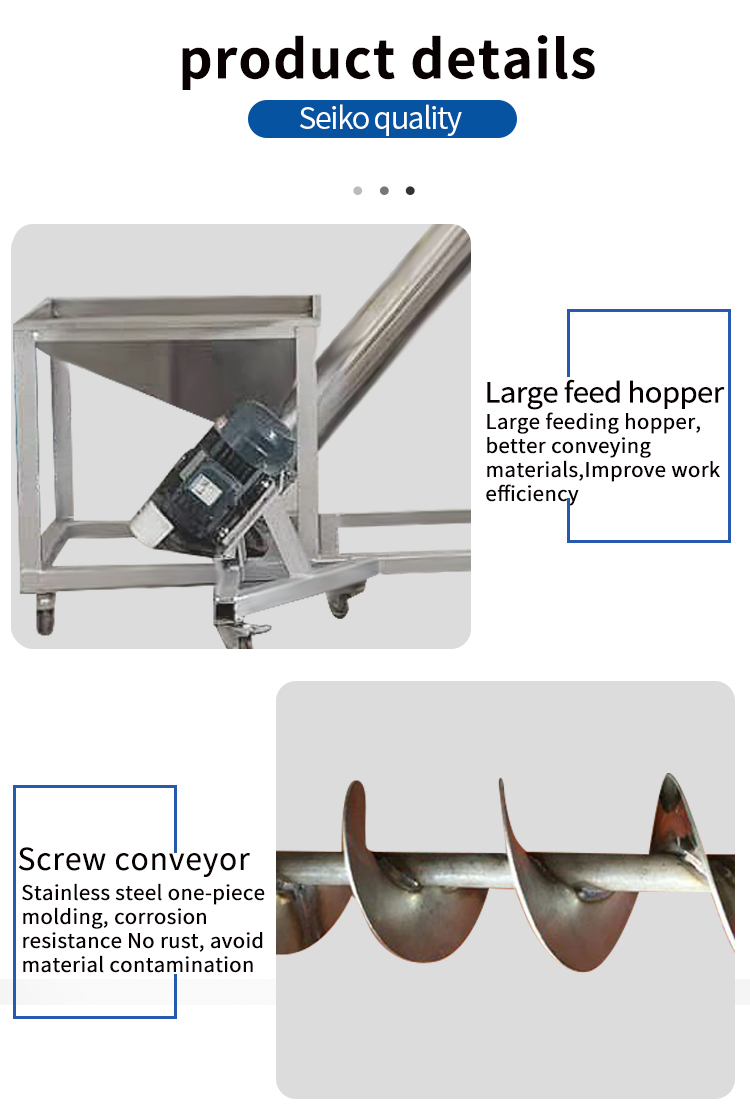

4. The feeding machine has the advantages of simple structure, small footprint, and high efficiency.

Characteristics of Spiral Feeding Machine

Wide temperature range, good anti adhesion, can be equipped with a baffle, large lifting angle, easy to clean, and simple maintenance.

Used for transportation in various environments, suitable for various special occasions and purposes.

It has the characteristics of high strength, acid resistance, alkali resistance, salt water, etc., and is used for transportation in various environments

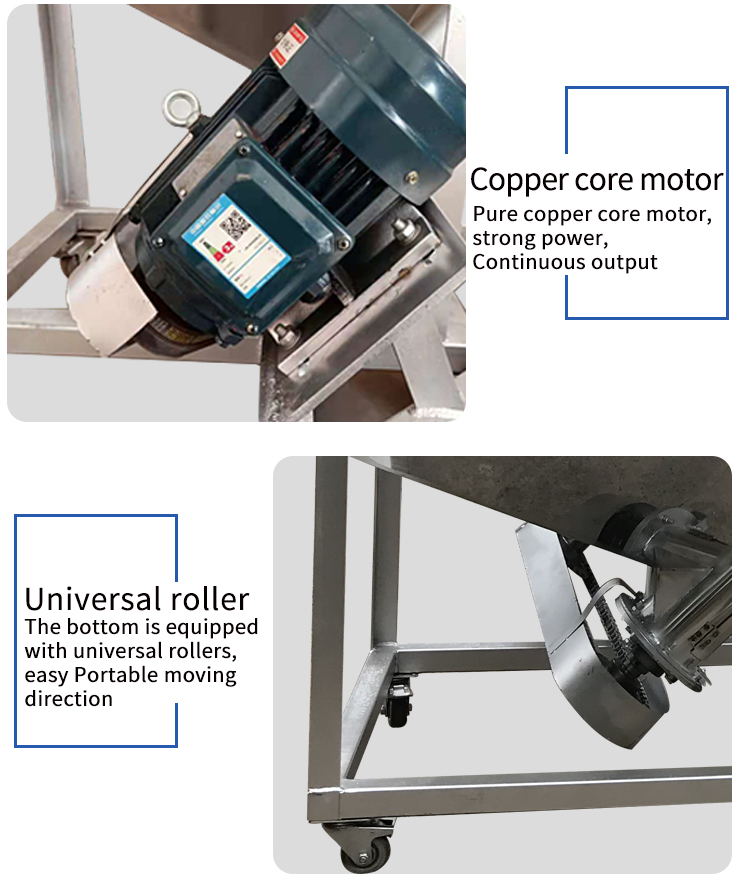

We can customize feeding machines of different specifications according to customer needs, such as hopper size, conveying height, motor position, etc.

The spiral feeder can automatically transport powdered or granular plastic raw materials directly into the hopper, or into containers such as high-speed mixers and mixers. The parts that come into contact with the raw materials are made of stainless steel, and the raw materials are completely free from contamination and foreign objects during the transportation process, achieving fully enclosed automation in the production process. Very suitable for professional machines that transport powders and small particles from bottom to top and in parallel, and can be matched with other equipment to achieve automation.

The working principle of stainless steel conveyor: The motor generates power, which is transmitted through a belt or a cycloidal pin reducer to the screw. The material is squeezed forward by the rotation of the screw, and there is a forward push between the materials. The material is fed from the inlet and forced to be pushed to the outlet by the screw.