Today we are showcasing a circular screening machine

Vibrating screens are mostly used in food industry and chemical industry: sugar powder, starch, salt, Rice noodles, milk powder, soybean milk, egg powder, resin, paint, cosmetics, aluminum powder, copper powder, alloy powder, welding rod powder, electrolytic copper powder, electromagnetic materials, grinding powder, refractory materials, lime, quartz sand, etc.

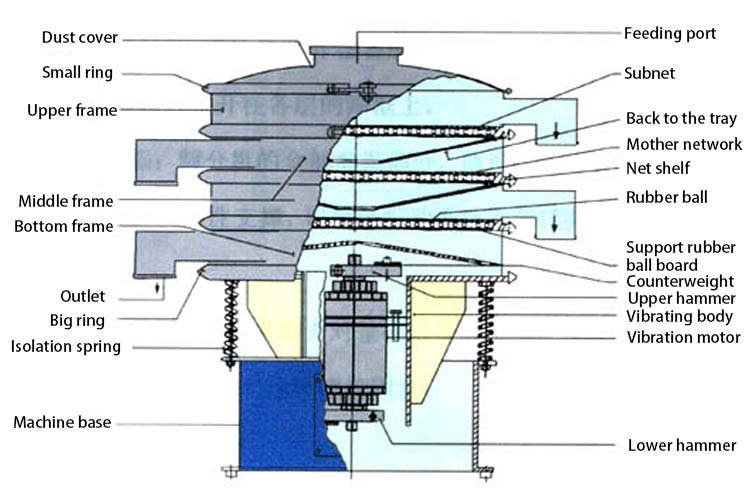

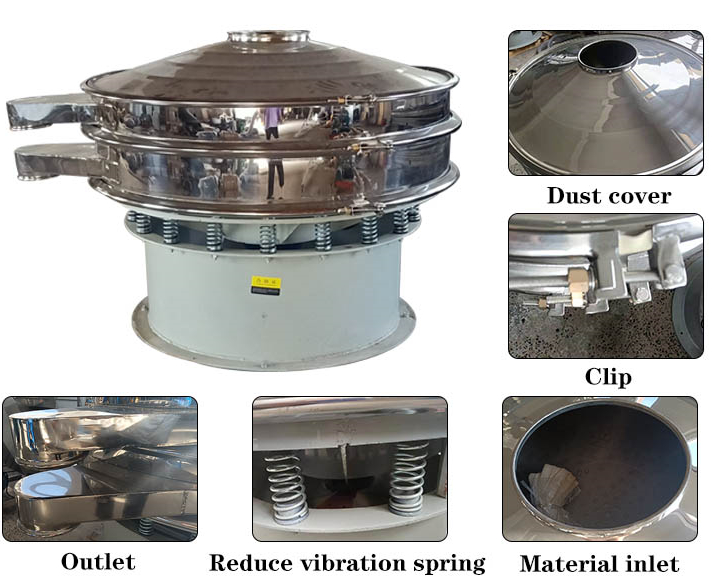

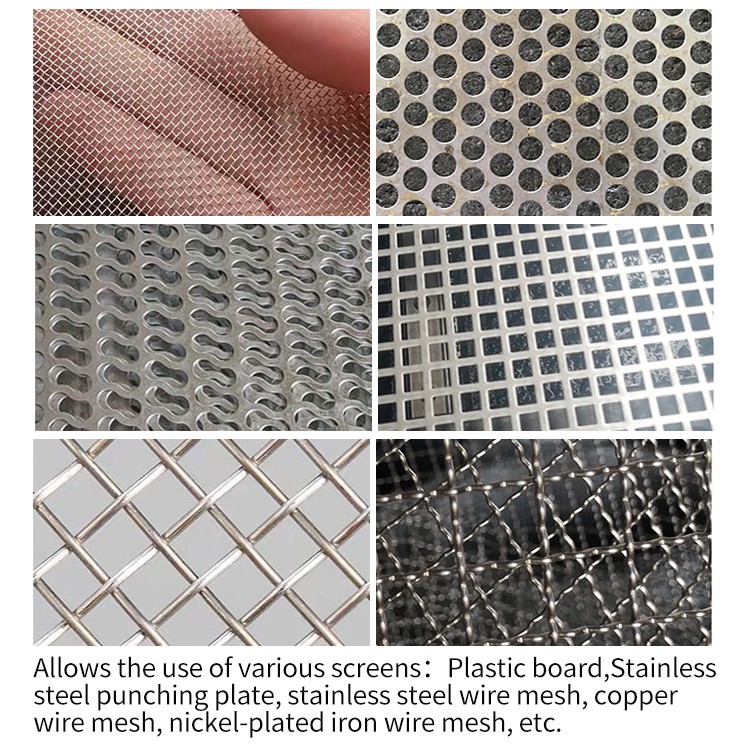

Introduction to vibrating screen: Circular vibrating screen is a high-precision fine powder screening equipment with low noise and high efficiency. It takes 3-5 minutes to quickly change the screen and has a fully enclosed structure. It is suitable for screening and filtering materials such as particles, powder, and mucus. The circular vibrating screen is excited by an upright motor, which is equipped with eccentric weights at the upper and lower ends of the motor. The rotating motion of the motor is transformed into horizontal, vertical, and inclined three-dimensional motion, which is then transmitted to the screen surface. Adjusting the phase angle between the upper and lower ends can change the motion trajectory of the material on the screen surface.

Characteristics of vibrating screen products:

1. High efficiency, exquisite and durable design, capable of screening any powder or mucus.

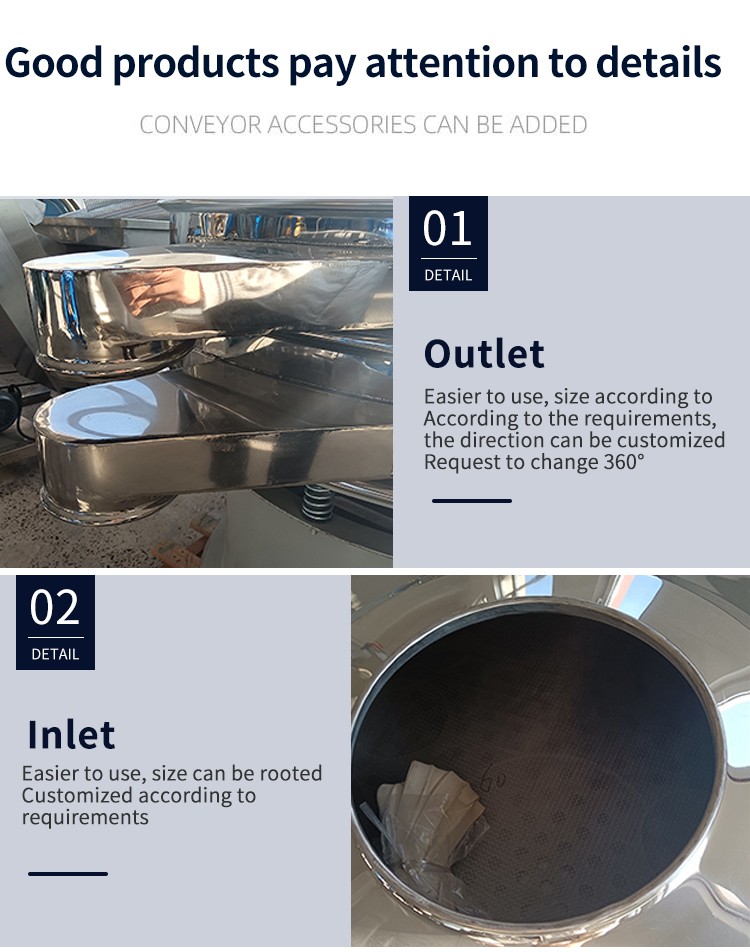

2. Easy to change mesh, easy to operate, and easy to clean.

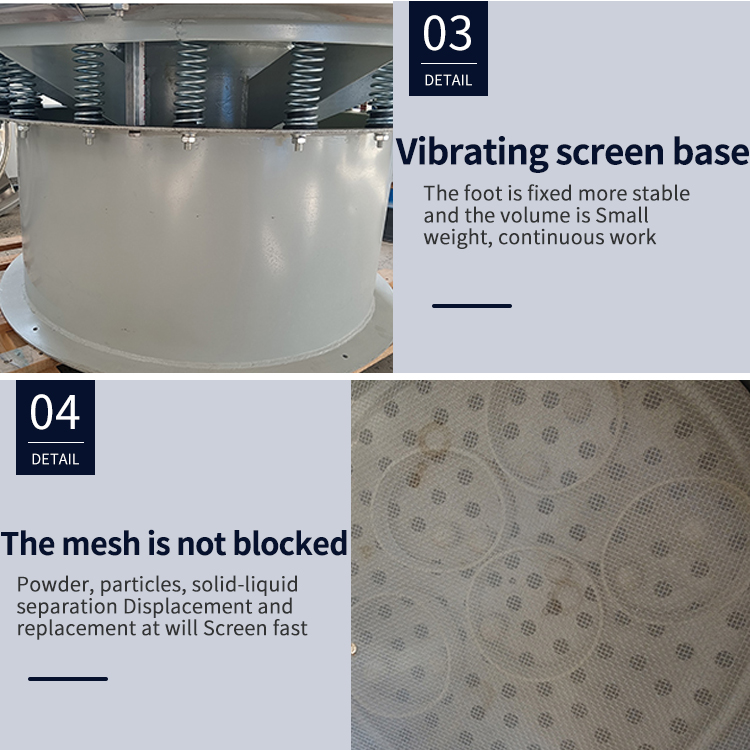

3. The mesh is not blocked, the powder does not fly, and can be sieved up to 500 mesh or 0.028mm.

4. Impurities and coarse materials are automatically discharged and can be operated continuously.

5. Unique mesh design, long-lasting use of the screen, fast mesh replacement, only 3-5 minutes.

6. Small size, space saving, and convenient mobility.

7. The screening machine can reach five layers, and it is recommended to use three layers.

Application scenarios and advantages of vibrating screens

Vibration screens are widely used in various scenarios such as material screening, classification, fragmentation, and dehydration. Its advantages include:

High throughput: The larger screening area enables high efficiency in material screening, with a production capacity of up to 2 tons per hour.

Multi layer separation: Up to 5 levels of grading can be achieved in a single operation, providing precise particle size distribution.

Adjustable: Equipped with an adjustable vibration motor, it can achieve different speeds and vibration levels according to the settings.

Efficient screening: It can effectively improve the efficiency and quality of aged garbage treatment, and is suitable for fine screening.