-

01-07 2026

Today, we will introduce an ink mixing reactor

A reaction kettle is a device used for conducting reaction processes, made of stainless steel such as SUS3O4 and SUS316L. It consists of a kettle body, jacket, stirrer, transmission device, shaft seal device, bracket (or ear), etc.

-

10-24 2025

Today, let's talk about the characteristics of stainless steel reactor

The high-speed dispersion reactor is made of SUS304/316 stainless steel material; The mixing method can be customized according to the characteristics of the material, such as paddle type, anchor type, frame type, screw type, scraping wall type, etc; Mechanical seals are commonly used as sealing methods; It is a device that implements the reaction process.

-

09-06 2025

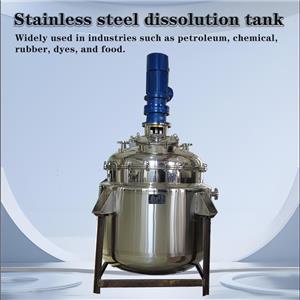

Today, I will show you a stainless steel dissolution tank

Stainless steel dissolution tank is an industrial equipment made of stainless steel material, used to achieve processes such as material dissolution and mixing. It is widely used in industries such as petrochemicals and food.

-

08-11 2025

Today we will talk about steam heating tanks

Steam heated mixing tank is a type of mixing equipment that uses steam as a heat source for heating, suitable for industries such as food and chemical, mainly used for material mixing, preparation, and reaction processes.

-

07-11 2025

Today, we will introduce an emulsifying equipment suitable for chemical plants

Emulsifying tank is an industrial equipment used to mix incompatible liquid or solid suspensions evenly to form a stable emulsion, widely used in industries such as food, cosmetics, and chemical.

-

06-07 2025

Today, we will introduce a steam heated reaction kettle

Stainless steel reaction vessels have the characteristics of rapid heating, high temperature resistance, corrosion resistance, hygiene, no environmental pollution, no need for boiler automatic heating, and convenient use. They are widely used in petroleum, chemical, rubber, dyes, food, and other processes such as vulcanization, nitrification, hydrogenation, alkylation, polymerization, and condensation.

-

05-20 2025

Today let's take a look at the mixing forms of mixing tanks

Stainless steel mixing tanks have various mixing methods and can be processed and manufactured according to the material characteristics and process requirements of users.

-

03-15 2025

Today we will talk about how to distinguish between mixing tanks and reaction vessels

There are many similarities in function and use between mixing tanks and reaction vessels, both of which are used for stirring liquid materials. The difference lies in the structure: the mixing tank is mostly a top flat cover structure, while the reaction kettle is a top and bottom head structure.

-

03-03 2025

What industries are mixing tanks used for

A mixing tank is used for mixing, blending, blending, and homogenization of materials. Stainless steel mixing tanks are designed with standardized and user-friendly structures and configurations according to the requirements of production processes. Mixing tanks are widely used in industries such as coatings, building materials, chemicals, pigments, resins, food, and scientific research. This device can be made of materials such as carbon steel and stainless steel according to the process requirements of the user's product, and equipped with heating and cooling devices to meet different process and production needs.

-

02-13 2025

Today we will talk about liquid mixing equipment

As the name suggests, a mixing tank is used to stir, mix, blend, homogenize, and disperse materials. Stainless steel mixing tanks are designed with standardized and user-friendly structures and configurations according to the requirements of production processes. The mixing tank can achieve feed control, discharge control, mixing control, and other manual and automatic controls during the mixing process.