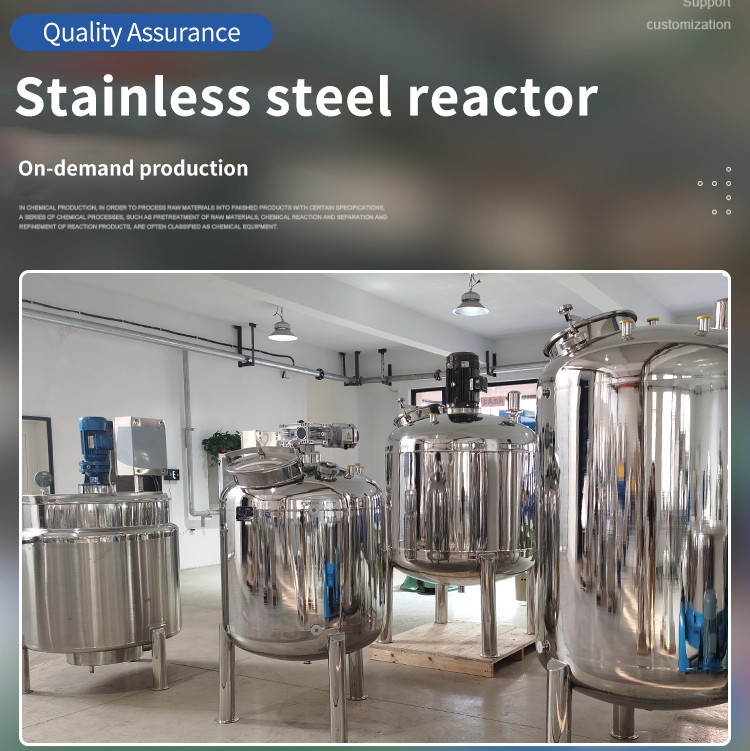

Today, we will introduce an ink mixing reactor

Vacuum reaction vessels are mainly used in industries such as chemical, coatings, pigments, resins, food, building materials, resins, agriculture, and scientific research, according to customer production processes and needs. Make regular or heated type; The equipment has a reasonable structural design, advanced technology, durability, and is characterized by simple operation and easy use.

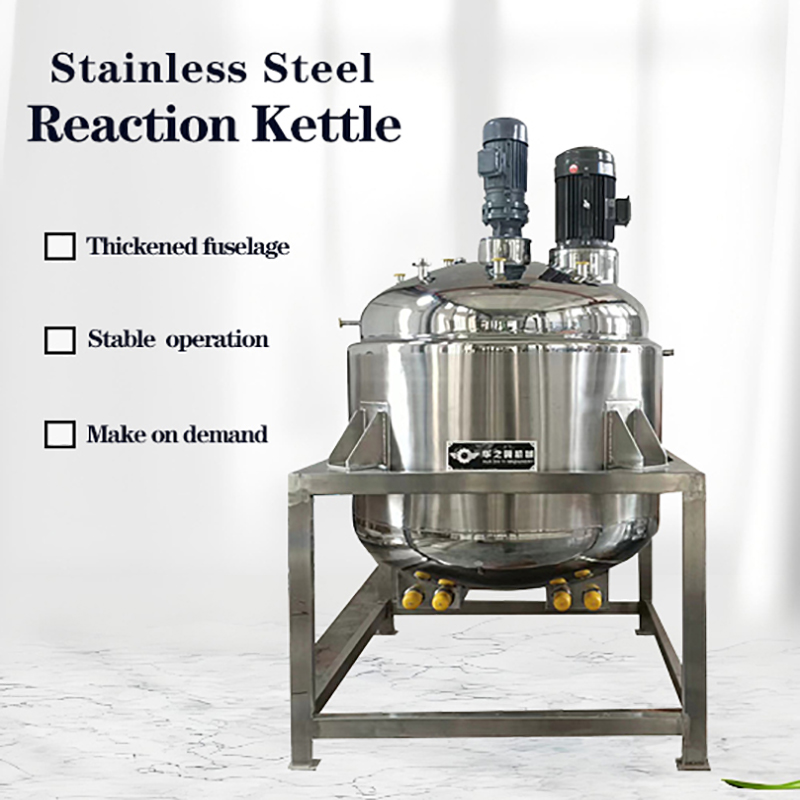

A vacuum reactor is composed of a stainless steel tank body, a stainless steel upper cover, a stirring device, a supporting device, a transmission device, a shaft sealing device, etc. The stirring tank body and the upper cover can be connected by welding or sealed by a cylinder flange. We can provide process pipe holes for feeding, discharging, sight glass, temperature measurement, liquid level measurement, pressure measurement, steam distillation, safety venting, etc. according to the customer's process requirements. The cycloidal pin reducer is driven by an electric motor, and then the agitator inside the mixing tank is driven by a transmission shaft to thoroughly mix the materials; Various forms such as atmospheric pressure flat cover, mechanical seal type, and labyrinth seal can be processed according to requirements.

Introduction to Reactor Equipment:

1. Material: Made of stainless steel materials such as SUS3O4 and SUS316L.

2. Agitators: anchor type, frame type, paddle type, turbine type, scraper type, dispersing disc type, combination type.

3. Rotating mechanism: cycloidal pinwheel reducer, continuously variable speed reducer or variable frequency speed regulation, etc.

4. Sealing device: mechanical seal, packing seal and other sealing structures.

5. Heating and cooling devices: jacket, half tube, coil, Miller plate, etc.

6. Heating methods include steam, electric heating, and thermal oil.

7. Pressure inside the kettle: normal pressure, positive pressure, negative pressure.

8.The discharge method includes manual ball valve, pneumatic valve, solenoid valve, and downward expansion valve.

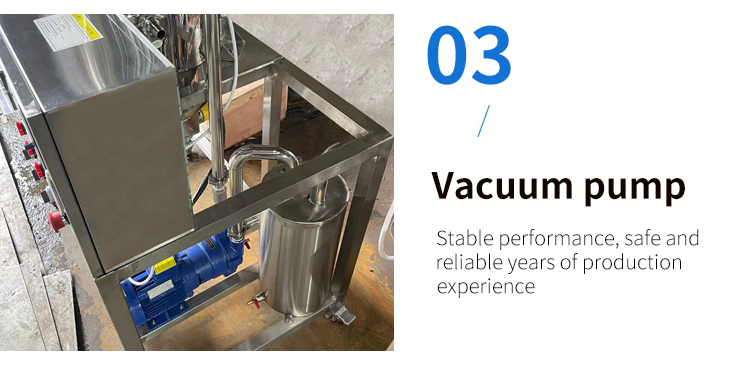

Requirements for the use of the reactor sealing device:

1. Packing sealing is usually used under normal or low pressure conditions, with a pressure of less than 2 kilograms.

2. In general, mechanical seals are used for medium pressure or vacuum situations, with a pressure of negative pressure or 4 kilograms.

3. Magnetic sealing will be used under high pressure or high volatility of the medium, generally with a pressure greater than 14 kilograms. Except for magnetic seals that use water cooling, other sealing forms will increase the cooling water jacket when the temperature is above 12 degrees.