Today let's take a look at the mixing forms of mixing tanks

The liquid mixing tank is tailor-made according to customer requirements. To briefly introduce, it consists of a stainless steel tank body, stainless steel cover, mixer, support, transmission device, shaft seal device, etc. The mixing tank body and cover can be connected by welding or by flange sealing; We can provide process pipe holes such as inlet, outlet, sight glass, temperature measurement, liquid level measurement, pressure measurement, steam distillation, and vent valve according to customer requirements. The cycloidal pin reducer is driven by an electric motor, and then the agitator inside the mixing tank is driven by a transmission shaft to thoroughly mix the materials; Various forms such as atmospheric pressure flat cover, mechanical seal type, and labyrinth seal can be processed according to requirements.

Classification of mixing tanks:

1. Classified by structural form: upper flat and lower cone, upper flat and lower oblique, upper flat and lower elliptical head.

According to the heating method, it can be divided into electric heating, oil heating, and steam heating.

3. Classified by volume size: specifications such as 10-5000L can be customized according to the actual needs of customers.

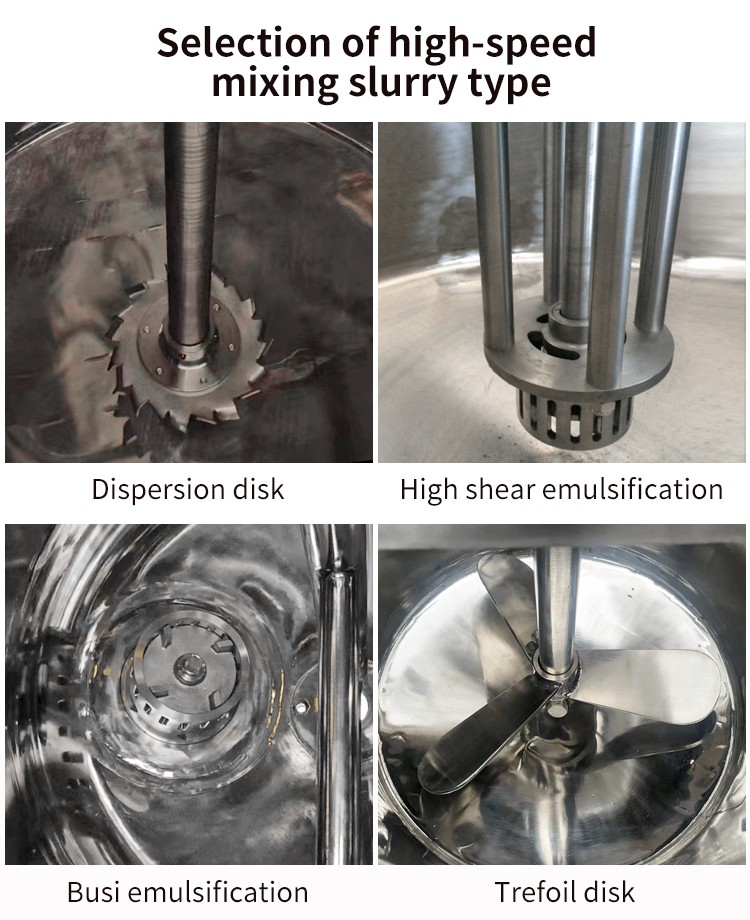

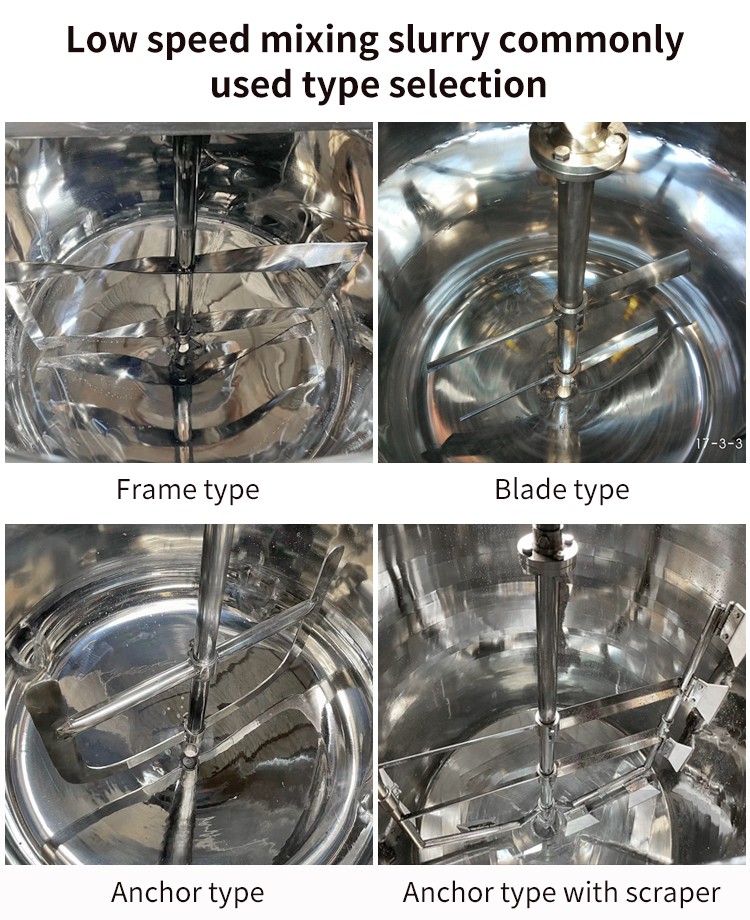

4. According to the mixing form, it can be divided into high-speed mixing, low-speed mixing, and combination type. High speed mixing includes high shear, uniform emulsification, bottom emulsification, spiral stirring, high-speed dispersion, etc; Low speed mixing includes frame mixing, anchor rod mixing, blade mixing, scraping wall mixing, etc.

5. Heating structure: jacket type, outer coil type, inner coil type.

Stainless steel mixing tanks can choose the mixing form according to customer process requirements and material characteristics. Blade characteristics:

1. Anchor type and frame type are generally used at low speeds between 60 and 300 rpm. This is because considering that anchor type and frame type have lengths of 3 to 5 meters and support points located at the shaft head, the strength of the mixing shaft is limited. At high speeds, the mixing shaft has a relatively large jumping amplitude, especially the shaking amplitude at the bottom of the mixing vessel, which may even touch the inner wall of the reaction vessel. At the same time, the rotation speed should be selected based on the viscosity of the material. For high viscosity, the rotation speed should be low, while for low viscosity, the rotation speed should be appropriately high.

2. Turbo type: With a large number and variety of blades, and high rotational speed, the fluid moves uniformly from vertical to horizontal direction.

3. Propulsion type: Propulsion type, also known as propeller type, is often cast as a whole. When welding, it is difficult to process by forging and then welding it to the shaft sleeve. Static balance experiments should be conducted during manufacturing. Can be connected to the shaft using shaft sleeves, flat keys, and set screws.

Characteristics of mixing tank:

1: Suitable for stirring, color mixing, blending, and homogenization of powders and liquids, or liquids and liquids;

2: Design the structure and configuration according to the customer's production process requirements; More standardized and humanized;

3: During the mixing process, feeding control, discharging control, mixing control, and other manual and automatic controls can be achieved;

4: It can be purchased separately or as a set according to the actual situation of the customer;