Today, we will introduce a steam heated reaction kettle

Reactors are widely used in industries such as coatings, building materials, pigments, resins, food, and scientific research. Suitable for mixing and stirring different materials, such as shampoo, shower gel, cosmetic water emulsion, adhesive, ink, paint,etc. It can also be used to mix, dissolve, and evenly mix and stir according to customer requirements. It can also be made into a physical equipment with functions such as heating, homogeneous emulsification, temperature control, and cooling according to customer requirements.

There are various heating and cooling methods for reaction vessels, and the following are some common types:

Heating method

-Electric heating: By installing electric heating elements such as heating rods, heating wires, etc. in the jacket or inside of the reaction vessel, electrical energy is converted into thermal energy to heat the materials inside the reaction vessel. The advantages are fast heating speed, precise temperature control, and clean and pollution-free. The disadvantage is that the operating cost is higher when the power is large.

-Steam heating: Using steam as a heat medium, heat exchange is carried out through a reactor jacket or coil. The advantages are high thermal efficiency, uniform temperature, and easy control of steam pressure and temperature, making it suitable for large-scale production. The disadvantage is that it requires auxiliary equipment such as steam boilers, and the system is relatively complex.

-Thermal oil heating: Using thermal oil as the heat transfer medium, the thermal oil is driven by a circulation pump to flow in the jacket or coil of the reaction vessel. The advantage is that it can achieve higher temperatures at lower pressures, with a wide temperature control range, and good thermal stability of the heat transfer oil. The disadvantage is that the thermal oil needs to be replaced regularly and there is a certain risk of leakage.

Cooling method

-Water cooling: Cooling water is introduced into the jacket or coil of the reaction vessel to remove heat. The advantages are good cooling effect, low cost, and wide water source. The disadvantage is that it requires high water quality, is prone to scaling, and requires anti freezing measures in cold regions during winter.

-Air cooling: Using air as a cooling medium, heat is dissipated through fans or fins installed outside the reactor. The advantage is that it is clean, pollution-free, does not require additional cooling water sources, and is suitable for small reaction vessels with low temperature control requirements. The disadvantage is that the cooling efficiency is relatively low and is greatly affected by the ambient temperature.

Characteristics of stainless steel reaction kettle:

1. Stainless steel material has excellent mechanical properties, can withstand high working pressure, and can also withstand the impact of block solid material feeding.

2. It has excellent corrosion resistance and no rusting phenomenon.

3. Good heat resistance, with a wide working temperature range (-196-600 ℃). It does not oxidize and peel at higher temperatures, so it can be used for direct fire heating.

4. The heat transfer effect is better than that of an enamel reactor, with faster heating and cooling rates.

5. It has good processing performance and can be made into reaction kettles of various shapes and structures according to process requirements. The kettle wall can be polished and polished to prevent hanging of materials and facilitate cleaning.

Introduction to stainless steel reaction kettle:

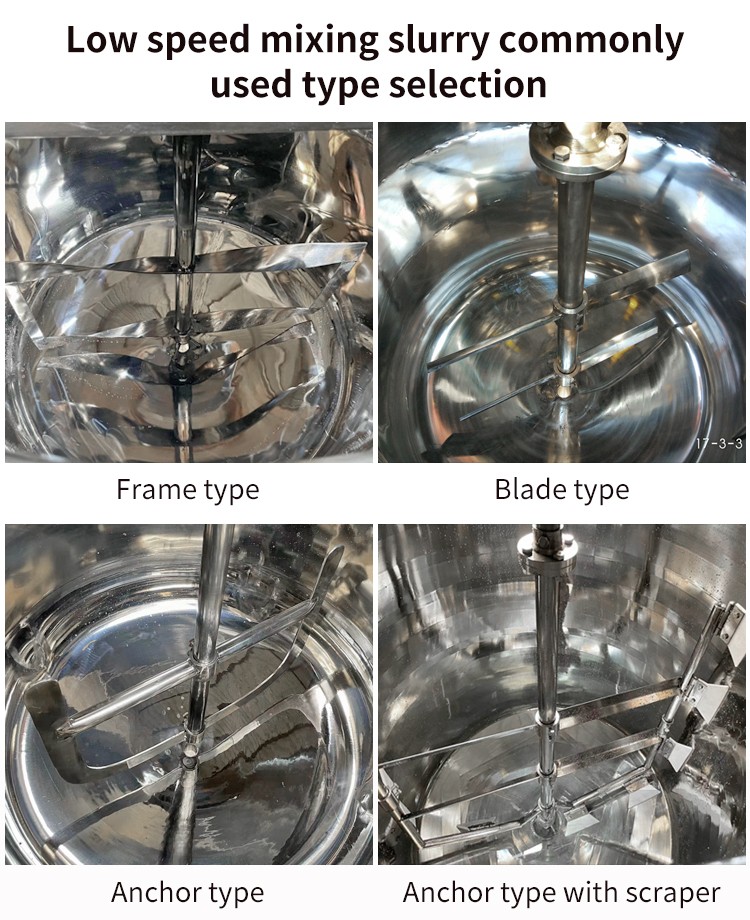

1. The mixing forms generally include paddle type, anchor type, frame type, screw type, scraping wall type, etc.

2. Heating forms include electric heating, oil heating, gas heating, water heating (or cooling), open flame heating, etc.

3. The jacket form is divided into: jacket type and outer half tube type, and the jacket oil heating type is equipped with a guiding device.

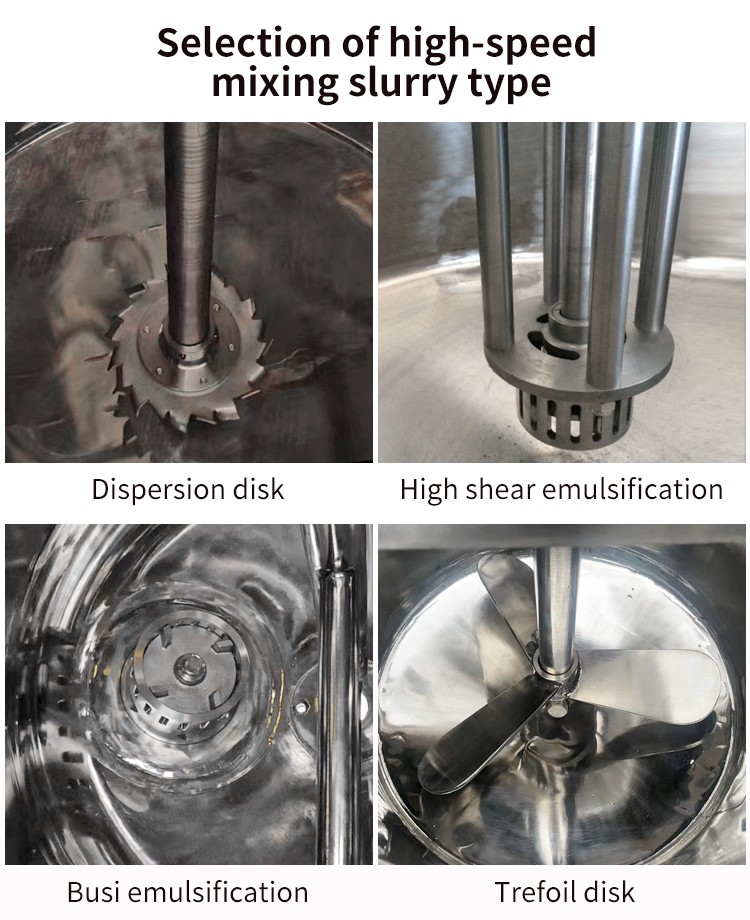

4. The mixing methods include low-speed mixing, dispersed impeller type, turbine type, high shear type, and propeller type, for customers to choose according to the process.

5. The sealing methods include ordinary water cooling packing seal, combined PTFE packing seal, and mechanical seal.

6. The discharge methods include manual ball valves, manual butterfly valves, pneumatic valves, electric valves, downward expansion valves, and so on.