Today, let's talk about the characteristics of stainless steel reactor

Stainless steel high-speed dispersion reaction kettle is mainly used in industries such as food, chemical, pharmaceutical, daily chemical, petroleum, etc., such as coatings, pigments, laundry detergent, detergent, shower gel, glue, resin, etc. It is a container used to complete processes such as hydrolysis, neutralization, crystallization, evaporation, and mixing.

A stainless steel reactor is a device used to carry out reaction processes, including single-phase liquid reactions and multiphase reactions such as liquid-liquid, gas-liquid, liquid-solid, and gas-liquid solid reactions. Stirring devices (mechanical stirring, air flow stirring, etc.) are often installed inside the kettle. When the aspect ratio is large, multi-layer stirring blades can be used. When the material needs to be heated or cooled during the reaction process, a jacket can be installed on the wall of the reaction vessel, or a heat exchange surface can be set inside the vessel, or heat exchange can be carried out through external circulation.

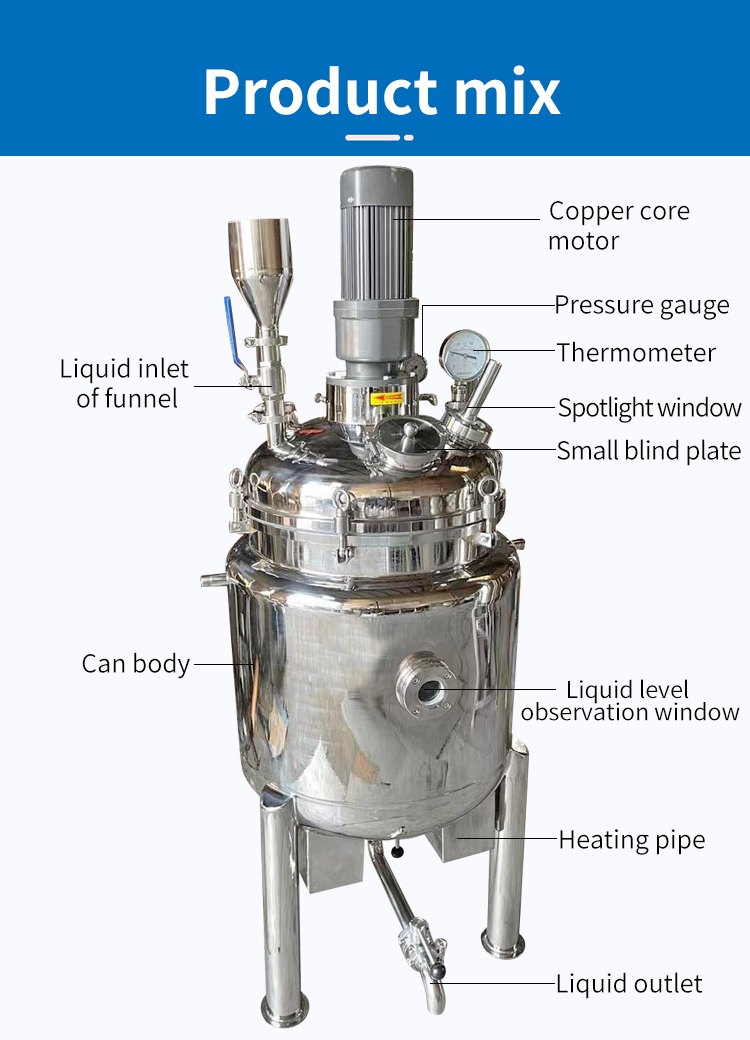

Structure and advantages of stainless steel reaction kettle:

1. The reaction kettle consists of a pot body, pot cover, stirrer, jacket, support and transmission device, shaft seal device, etc. The opening can be customized according to the user's process requirements. 2. Heating methods include electric heating, oil heating, steam heating, water heating (or cooling), open flame heating, etc.

3. The jacket forms are divided into jacket type and outer half tube type, and the jacket oil heating type is equipped with a flow guide device.

4. The mixing forms generally include paddle type, anchor type, frame type, screw type, scraping wall type, etc.

5. The high-speed category includes dispersed impeller, turbine, high shear, and thruster types, for customers to choose according to the process.

6. The transmission forms include ordinary motors, explosion-proof motors, electromagnetic speed regulating motors, frequency converters, etc. The heat exchangers include cycloidal pinwheel, worm wheel, and planetary continuously variable transmission. 7. The shaft seal includes ordinary water-cooled packing seal, combined PTFE packing seal, and mechanical seal.

8. The materials include SUS3O4 stainless steel, SUS316L stainless steel, and carbon steel. The discharge methods include manual ball valves, pneumatic valves, solenoid valves, and downward expansion valves.