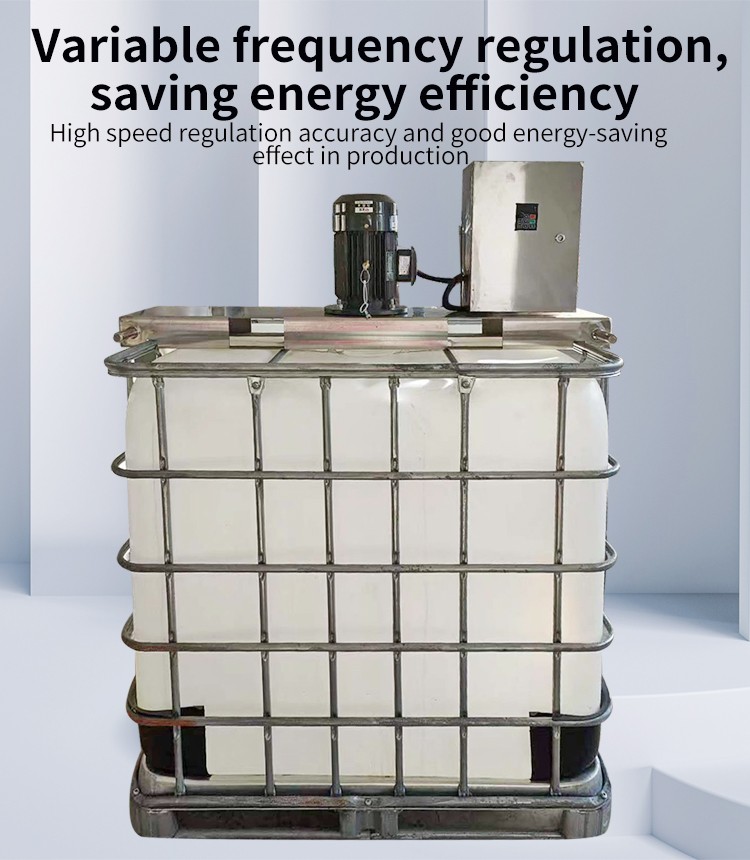

Today, let's take a look at how the IBC mixer works

The IBC bucket mixer adopts a horizontal plate frame on the IBC bucket frame, and is fixed on the bucket iron frame with two M10 handle screws at both ends. The mixing blades are equipped with two layers of extendable mixing blades, suitable for material buckets with a bucket mouth diameter of less than 150mm. The horizontal rack is equipped with 2 work holes for forklift extraction operations, making it convenient to lift the mobile mixer.

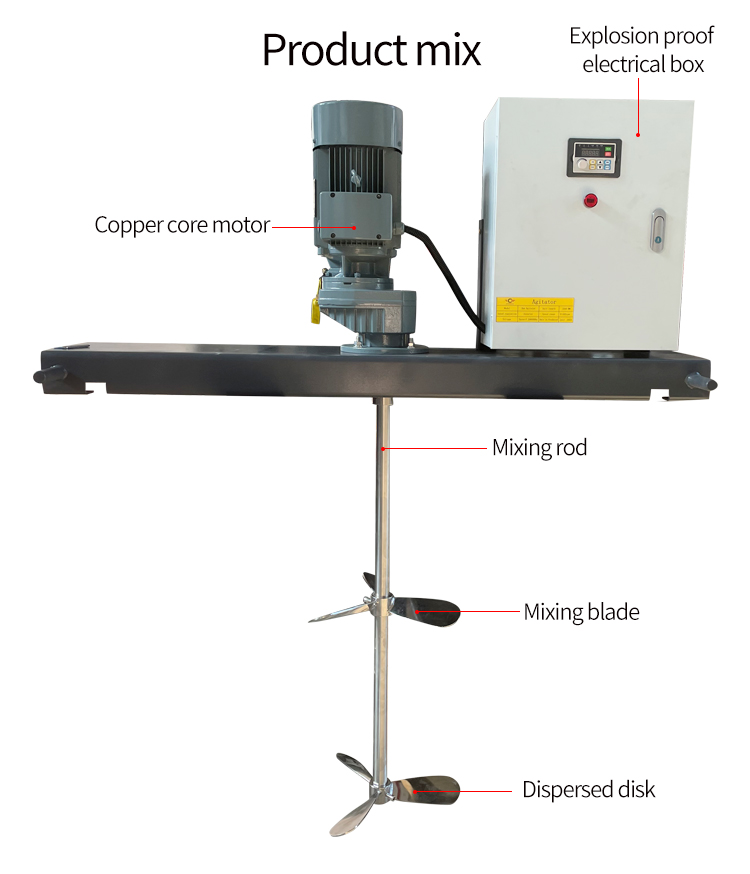

Technical characteristics of IBC ton drum mixer:

1. Adopting copper core motor, equipped with reducer, with high torque and strong power.

2. The part in contact with the liquid is made of SUS304 stainless steel material, which has good acid and alkali corrosion resistance.

3. The mixing shaft and blade are fixed with screws for easy disassembly.

4. The horizontal board is equipped with forklift extraction holes for easy forklift operation

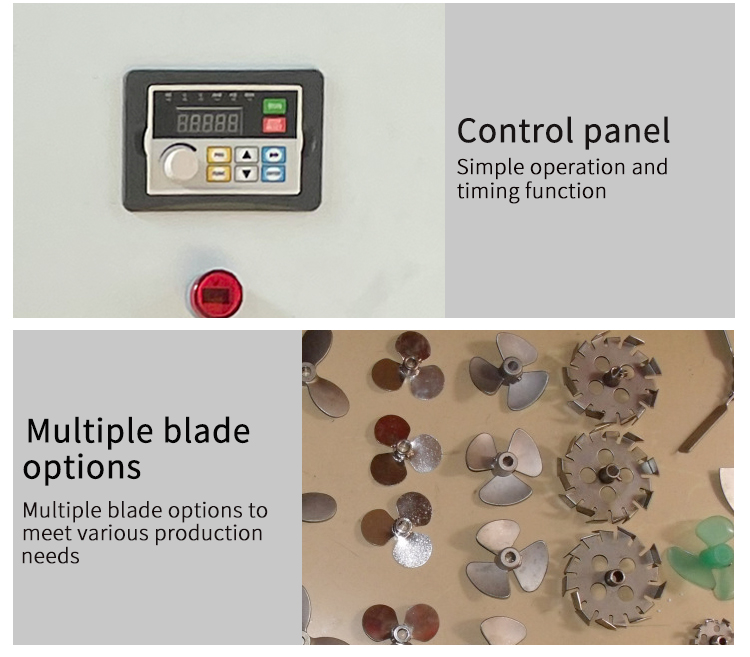

5. The mixer is equipped with variable frequency speed control, and the speed is adjusted according to the demand.

Technical characteristics of IBC mixer:

1. The liquid contact part is made of SUS304 stainless steel.

2. High-quality brand motor is adopted, with large torque, strong power and wide mixing range.

3. The mixing shaft and paddle are fixed with screws for easy disassembly.

4. The cross plate is equipped with a forklift hole to facilitate the lifting and movement of the forklift and reduce manpower.

5. Both ends are fixed with clamps.

6. The electric mixer is equipped with variable frequency speed control, and the speed can be adjusted according to the demand.

IBC agitator hydraulic lifting type high-speed disperser, the dispersing disk is driven by the motor at high speed, generating high linear velocity rotation. Under the action of huge centrifugal force, it produces strong hydraulic shear and high-frequency mechanical effects, making the fluid material withstand tens of thousands of shear and high-frequency mechanical effects per minute, thus achieving the effect of mixing and dispersion. Widely applicable to industries such as coatings, dyes, inks, papermaking, adhesives, and chemicals. Mixing, blending, dissolving, and dispersing two or more liquid and solid powders.

IBC lifting mixer features:

1. The high-speed disperser is suitable for pre mixing, dispersing, and color matching of powder liquid phase and liquid-liquid phase;

2. High production efficiency, hydraulic lifting, and flexible frame rotation:

3. During stirring and dispersion, air absorption is minimal, which can quickly dissolve the material and reduce particle size

4. Good mixing and blending effects:

5. This model is particularly suitable for large-scale production selection.