-

11-26 2025

Today, let's talk about how to maintain a colloid mill

Colloidal mill is an equipment used for fine processing of materials, which is divided into two structures: vertical and split. Its structure is simple and easy to operate.

-

10-16 2025

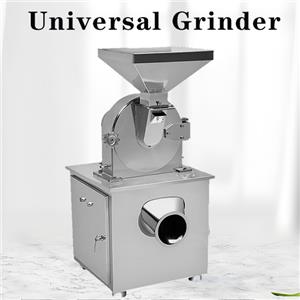

Today we will talk about the advantages of universal crushers

The universal crusher is a grinding equipment made of stainless steel material. Customers can suspend the grinding method according to their own material characteristics, adjust the mesh aperture, and control the particle size of the crushed material.

-

10-08 2025

Hello everyone, today we will talk about the grinder for chili sauce

Colloidal mills are divided into whole machine stainless steel or material contact stainless steel production, and are mostly used in industries such as food and chemical. Their principle is to shear and crush materials through high-speed relative linkage of fixed teeth and rotating teeth rotation.

-

09-27 2025

Today, we will introduce a chili grinding and crushing machine

The colloid mill is composed of stainless steel and semi stainless steel colloid mills. The basic principle of the colloid mill is that the fluid or semi fluid material passes through the high-speed relative movement between the fixed and moving teeth, causing the material to be subjected to strong shear force, friction force, and high-frequency vibration, effectively being crushed, emulsified, homogenized, and heated, thereby obtaining satisfactory precision processed products.

-

08-29 2025

Today we are going to try the universal crusher

Universal pulverizer is suitable for the food and chemical industries, with multiple pulverization methods. It utilizes the high-speed relative motion between the movable and fixed toothed discs to achieve pulverization through a combination of tooth impact, friction, and material impact.

-

08-02 2025

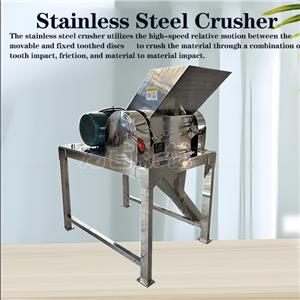

Today, let's talk about how to choose a stainless steel crusher

Stainless steel grinding is widely used in food, chemical plants, etc. It has the advantages of compact structure, small footprint, simple and easy maintenance, and high work efficiency.

-

07-26 2025

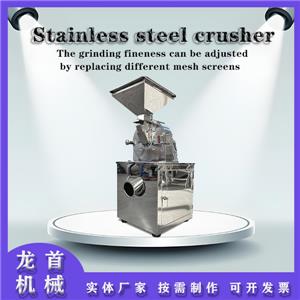

Today, let me introduce the advantages of stainless steel crushers

Stainless steel crusher is a crushing equipment made of stainless steel material, mainly used for processing food, chemical raw materials, etc. It has the characteristics of corrosion resistance and easy cleaning.

-

04-09 2025

Today, let me introduce the advantages of a universal crusher

Stainless steel crushers can be configured with different cutting tools according to the characteristics of customer materials, and are used in industries such as food, traditional Chinese medicine, and chemical engineering.

-

02-27 2025

Hello everyone, today we will talk about stainless steel grinding machines

Colloidal mill consists of a shell,rotor, regulating mechanism, cooling mechanism, motor, etc. It is a machine used for fine machining, which is suitable for homogenization, emulsification, dispersion, and mixing of various materials through high-speed relative linkage between fixed teeth and moving teeth for shearing, grinding, and stirring.

-

02-27 2025

Hello, today we will talk about stainless steel grinding machines

Colloidal mill consists of a shell, stator, rotor, regulating mechanism, cooling mechanism, motor, etc. It is a machine used for fine machining, which is suitable for homogenization, emulsification, dispersion, and mixing of various materials through high-speed relative linkage between fixed teeth and moving teeth for shearing, grinding, and stirring.