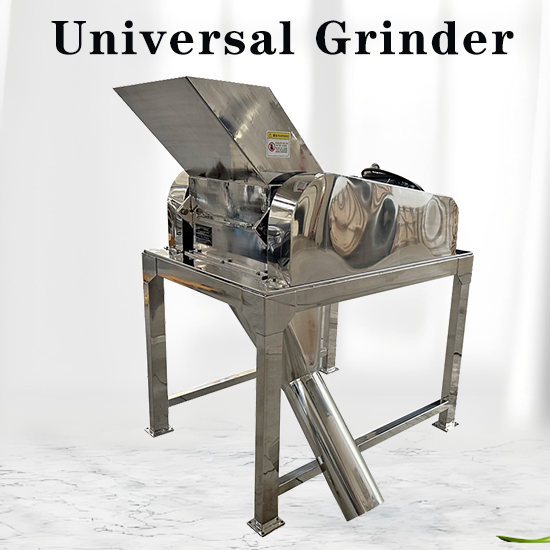

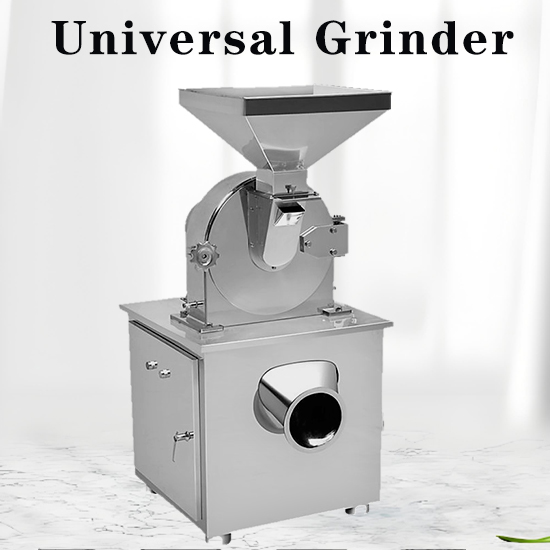

Today we will talk about the advantages of universal crushers

The universal crusher has a simple, sturdy structure, smooth operation, and excellent crushing effect. The crushed material can be directly discharged from the grinding chamber of the main machine, and the particle size can be obtained by replacing the mesh screen with different aperture sizes. Universal crusher is suitable for grinding and crushing granular and block materials in various industries such as food, chemical, and grain; To crush wet materials such as hawthorn, corn, ginger, garlic, red chili, etc., they need to be dried first and then crushed with a grinder.

Product features of universal crusher:

1. The whole machine is made of 304 stainless steel material. If requested by the customer, the material of the cutterhead and screen mesh are both made of 304 stainless steel.

2. Pricing High ratio, easy to operate, stable operation, low noise, easy to clean, large air volume, fast discharge, high output.

3. The discharge size can be adjusted by replacing the sieve with different aperture sizes.

4. Adopting a high-speed rotating blade with impeller, the impeller generates strong wind force during high-speed operation, making it less likely for the machine cavity to heat up and materials to block the machine.

5. Equipped with bag type dust removal box and cyclone collection to purify the air, the production process is dust-free, and the dust can be recycled and reused.

6. Equipped with a water cooling system, the bearing water cooling system has a low inlet and high outlet water pipe, which is used to cool the high temperature caused by the high-speed rotation of the bearing and extend the service life of the machine. When some thermosensitive materials are prone to softening and difficult to crush at high temperatures, a crusher with a cold water or cold air jacket inside the chamber can be used.

Instructions for using the crusher:

1. Before starting up, it is necessary to check whether the door is tightly closed. When closing the door, tighten the handwheel and positioning bolts.

2. Connect the water cooling device to ensure sufficient water supply, and it is strictly prohibited to cut off water during operation.

3. When installing, turn on the power and electrically check whether the motor rotates in the direction indicated by the arrow. If it is the opposite, please adjust the wiring of the motor junction box.

4. With the motor rotating in the correct direction, start and idle for 30 minutes, check the lubrication condition, and add lubricating grease in a timely manner. Regularly inspect and replenish lubricating grease.

5. Before feeding, air rotate for a few minutes, then slowly and evenly add the material. Do not fill the hopper completely, and pay attention to whether the current is overloaded to prevent damage to the equipment.

6. If there is any significant vibration or noise during operation, it should be promptly shut down for inspection.

7. Regularly maintain lubrication and cleanliness of machinery, and promptly repair or replace any faults or defects found.