Today, let's talk about how to maintain a colloid mill

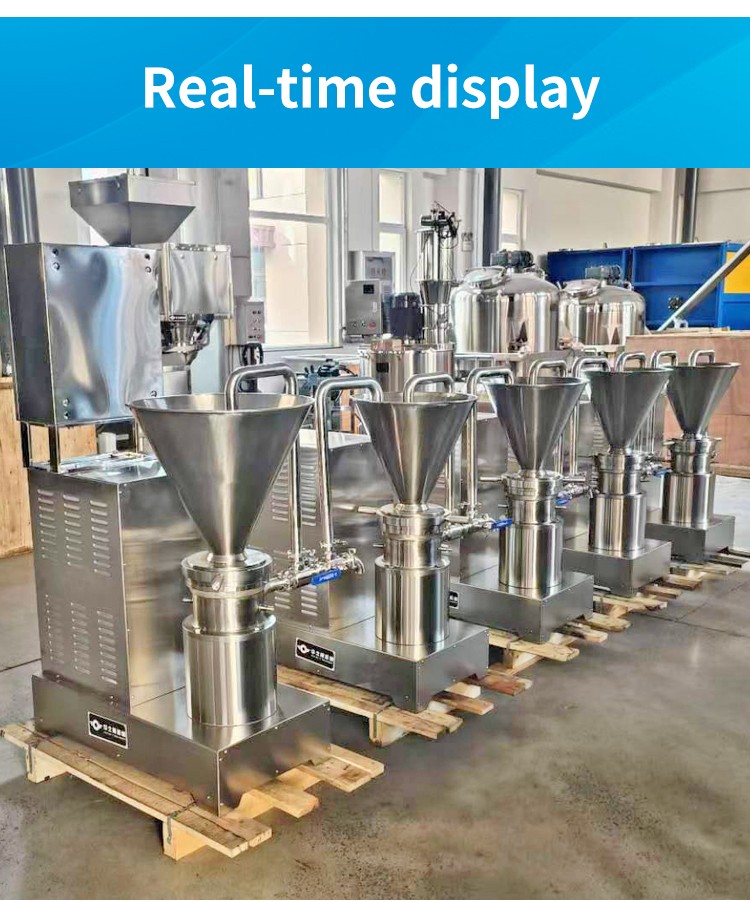

Application scope of stainless steel colloid mill: In the food industry, it can be used for processing dairy products, chocolate, jam, vegetables and fruits, royal jelly, etc; In the chemical industry, it can be used for the production of pigments, lubricants, paints and coatings, etc; In daily chemical industry, it can be used for the manufacturing of shoe polish, toothpaste, cosmetics, etc.

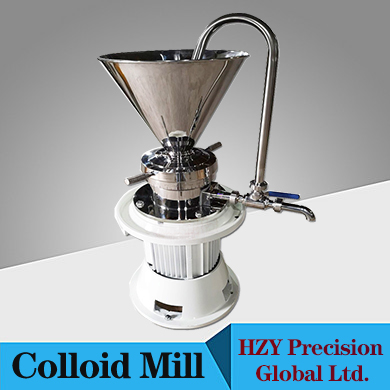

The colloid mill is composed of stainless steel and semi stainless steel colloid mills. The basic principle of the colloid mill is that the fluid or semi fluid material passes through the high-speed relative movement between the fixed and moving teeth, causing the material to be subjected to strong shear force, friction force, and high-frequency vibration, effectively being crushed, emulsified, homogenized, and heated, thereby obtaining satisfactory precision processed products.

Colloid mill discharge port:

1. The circulating pipe is suitable for materials with low viscosity that need circulating reflux grinding, such as soybean milk, fruit and vegetable juice, drinks, etc.

2. Fangkou is suitable for materials with medium to high concentrations that do not require reflux grinding, such as peanut sauce, chili sauce, minced meat, etc.

Precautions for colloid mill: Colloidal mill can only perform wet processing and cannot process dry solid materials. The material particle size should be less than 1m and the hardness should not exceed HV309. The equipment should be installed horizontally, and each component should be checked for normal operation before use. After operation, residual materials inside the stator and rotor should be cleaned in a timely manner.

The maintenance of colloid mills should revolve around component inspection, cleaning, lubrication, and fault prevention. The specific operations are as follows:

1. Daily cleaning: After each use, dismantle the grinding head, stator, and rotor in a timely manner, clean up residual materials, avoid material drying and blockage, rinse with clean water and wipe dry after cleaning to prevent rust.

2. Lubrication and maintenance: Regularly check the lubricating oil level of bearings and gearboxes, add suitable lubricating oil or grease according to the equipment instructions, and generally replace the lubricating oil every 1000 hours of operation.

3. Component inspection: Before operation, check whether the clearance between the fixed teeth and the moving teeth is normal. If there is wear or deformation, it should be adjusted or replaced in a timely manner; At the same time, check the seals, such as sealing rings and gaskets, and replace them immediately after aging to prevent leakage.

4. Shutdown storage: Before long-term shutdown, the equipment should be thoroughly cleaned, rust proof oil should be applied to the surface of metal parts, and placed in a dry and ventilated environment to avoid direct sunlight and moisture erosion.

5. Operation monitoring: Pay attention to the sound and temperature of the equipment during operation. If there is any abnormal noise or overheating (temperature exceeding 70 ℃), immediately stop the machine for inspection, troubleshoot and restart.