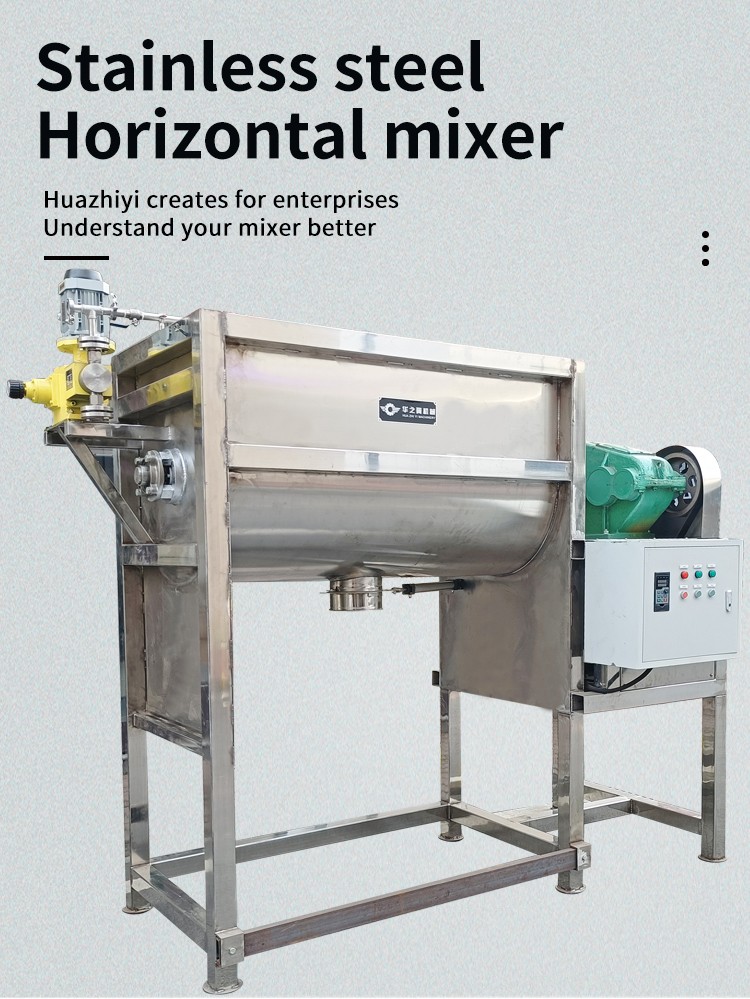

Today, let's talk about the maintenance of horizontal mixers

Horizontal mixers are mainly used for mixing two or more materials, pre mixed materials, and are suitable for industries such as food, daily chemical, seasoning, etc., such as milk powder, cereal powder, soy milk powder, seasoning products, salt, coffee, milk tea, flour, laundry detergent, talcum powder, pigment powder, coating powder, cement powder, rare earth and other solid solid (i.e. powder to powder) and solid slurry (i.e. powder to slurry) mixing.

Horizontal mixers are mainly used for mixing two or more materials, pre mixed materials, and are suitable for industries such as food, daily chemical, seasoning, etc., such as milk powder, cereal powder, soy milk powder, seasoning products, salt, coffee, milk tea, flour, laundry detergent, talcum powder, pigment powder, coating powder, cement powder, rare earth and other solid solid (i.e. powder to powder) and solid slurry (i.e. powder to slurry) mixing.

The working principle of a horizontal mixer is to arrange double-layer spiral blades on the transmission spindle, with internal and external spirals (small spiral belts) conveying materials to the outside, and external spirals (large spiral belts) pushing materials inward. Under the convective motion of the double spiral belts, the materials form a low power and high efficiency mixed environment. The inner and outer diameter screws installed on the mixing shaft drive the material inside the barrel, causing the agitator to flip the material within a certain range inside the barrel. When the mixing device is working, the inner screw drives the material near the axis to rotate axially, pushing it from the inside to both sides. The outer screw drives the material near the barrel wall to rotate axially, pushing it from both sides to the inside, allowing the mixed material to mix evenly in a short period of time.

Precautions for horizontal mixer:

1. It is necessary to regularly clean the inner wall of the mixing drum (clean easily sticky materials once

a day, and non sticky materials once every three to five days) to keep the drum smooth and clean.

2. The bearing needs to be filled with yellow glycerin every half month to one month (if there is any

abnormal noise or discomfort, please replace the bearing with a new one according to the model).

3. The gear oil of the reducer needs to be replaced every six months to one year (if impurities in the

oil are not replaced in time, it will affect the service life of the reducer).

4. Pay attention to the tightness and wear of the belt (if there is wear, please replace it in time to

prevent the belt from slipping and insufficient power).

5. Keep the electrical control box dry and dust-free (excessive dust can cause electric shock and false

connection, posing serious safety hazards).