Today we will talk about circular vibrating screens

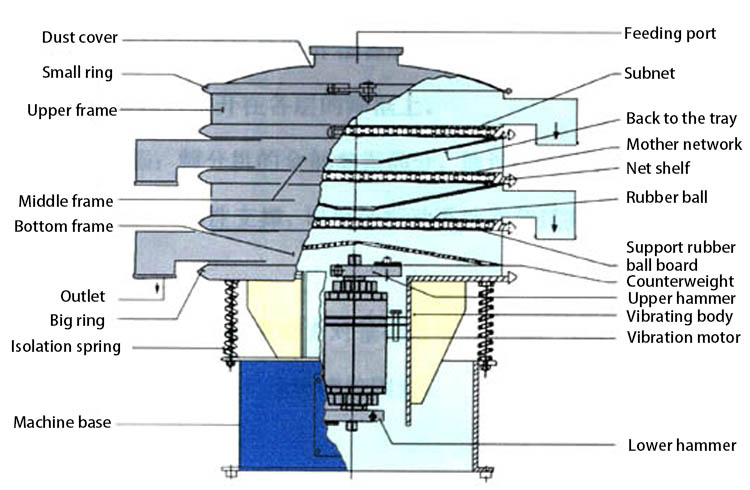

Stainless steel vibrating screen is a mechanical equipment that uses vibration to screen materials. It generally consists of a vibrating motor, isolation device, base, screen mesh, screen cover, screen frame, and other parts. Mainly used for grading, impurity removal, dehydration and other operations of particles, powders and other materials in production line operations in various industries such as chemical, metallurgical, building materials, ceramics, papermaking, food and feed processing.

The working principle of a circular vibrating screen is to use an upright motor as the excitation source. The periodic excitation force is generated by eccentric weights installed at the upper and lower ends of the vibration source motor, which converts the motor's rotational motion into horizontal, vertical, and inclined three-dimensional motion, and transmits it to the screen box, causing the screen to vibrate at high frequency. The material is subjected to vibration on the sieve surface, with particles smaller than the sieve aperture passing through and particles larger than the sieve aperture being discharged along the sieve surface, thus achieving classification.

Characteristics of vibrating screen products:

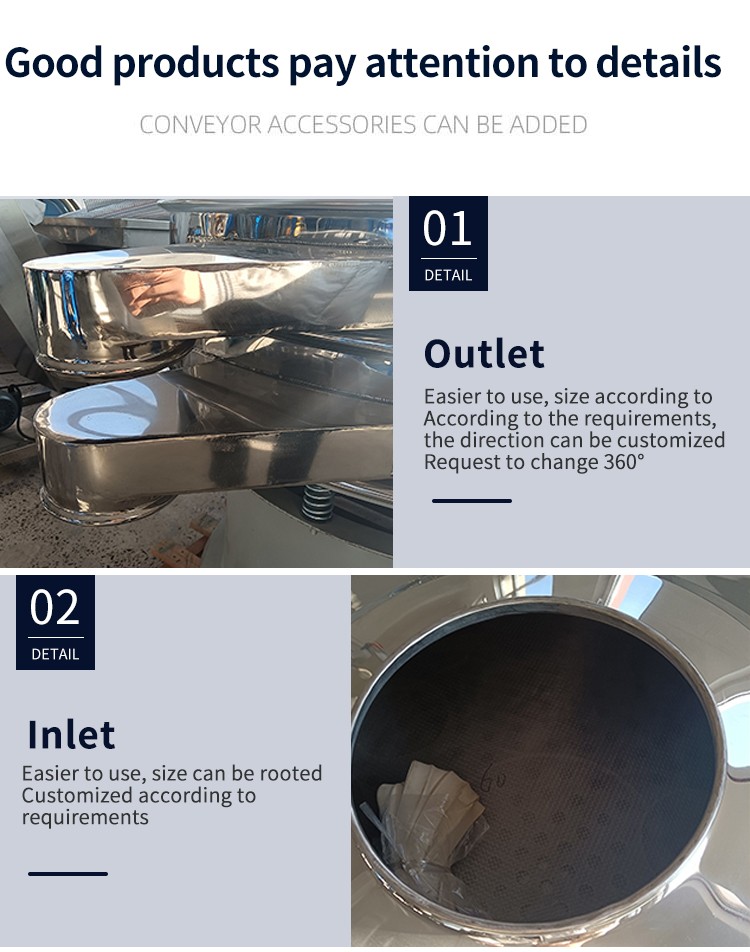

1. Fully enclosed design, high screening efficiency, exquisite and durable design, can screen any powder or mucus.

2. Easy to change the network, simple to operate, and easy to clean.

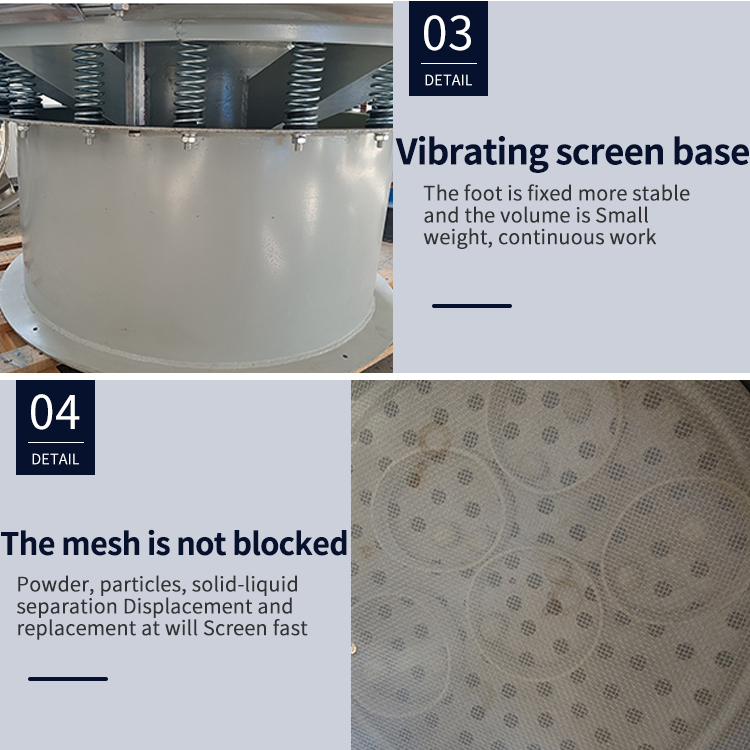

3. The mesh is not blocked, the powder does not fly, and it can be sieved up to 500 mesh or 0.028mm.

4. Impurities and coarse materials are automatically discharged and can be operated continuously.

5. Unique grid design, long screen usage time, fast screen replacement, only 3-5 minutes.

6. Small size, light weight, space saving, and easy to move.

7. The screening machine can reach five layers, and it is recommended to use three layers.

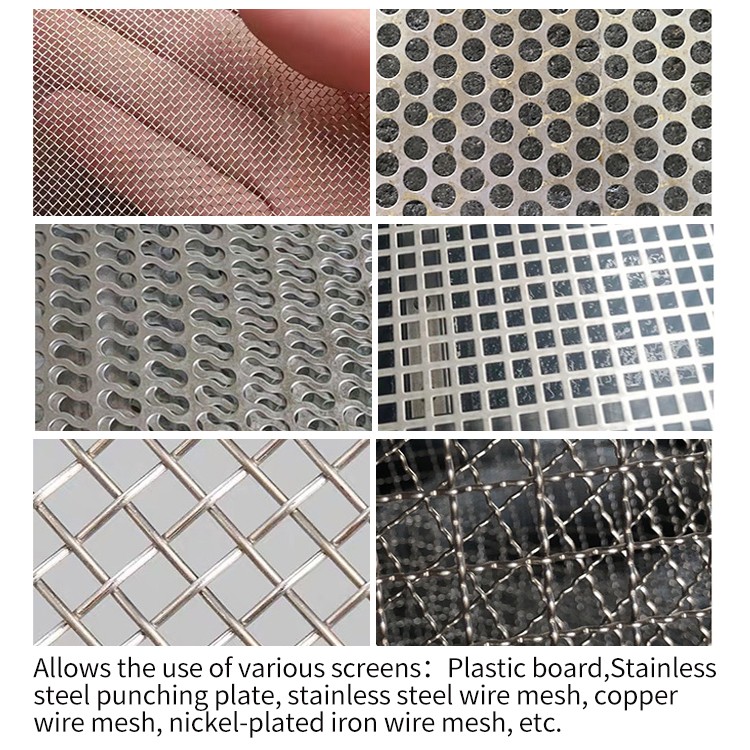

8.The circular vibrating screen adopts spring steel woven screen or perforated screen plate.

The sieve surface of a circular vibrating screen usually has two structural forms: single-layer and double-layer. The working principle of a circular vibrating screen is that after the screen machine is started, the vibrator of the screen machine drives the vibrating screen box to perform directional jumping motion together. During this process, materials smaller than the screen aperture fall to the lower layer through the screen aperture, becoming undersized materials. Materials larger than the screen aperture are discharged from the discharge port after continuous jumping motion. Complete screening work.