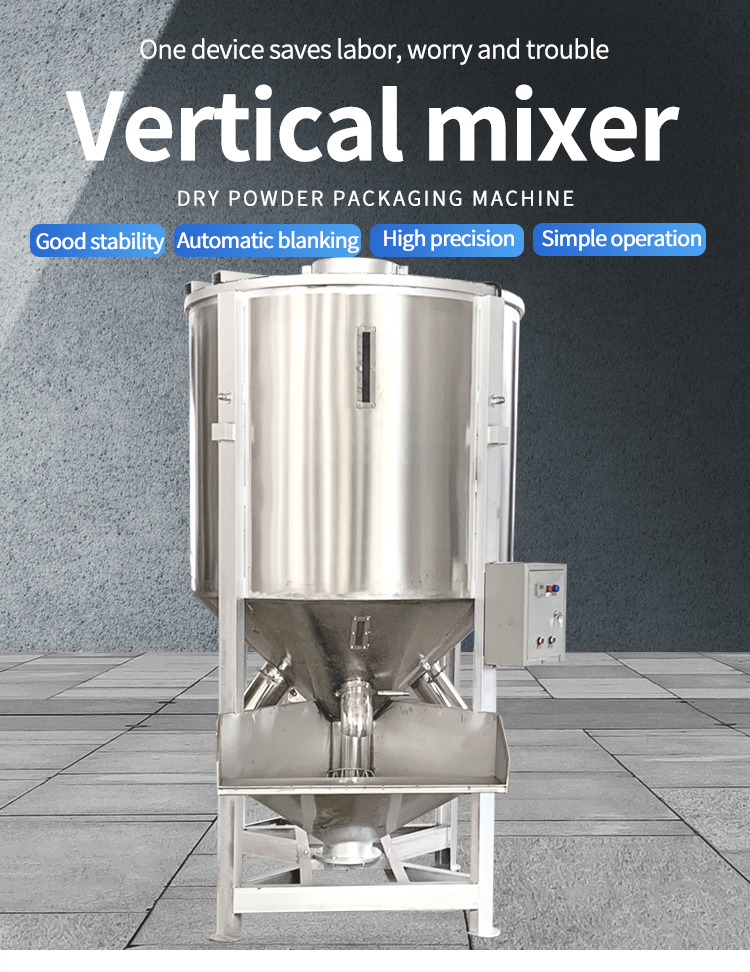

Today we will introduce a vertical mixer that can be dried

Vertical mixers can be widely used for mixing plastic sheets, crushed materials, plastic particles, new and old plastic materials, and adding colorants evenly; Equipped with automatic operation timing, overload protection and other functions; And it has the advantages of small footprint, large capacity, low power consumption, labor-saving, convenient operation, and fast and uniform mixing.

Introduction to Vertical Mixing Mixer:

1. Vertical design: easy to operate and easy to maintain

2. Capacity optional: A regular 1-10 ton model is available for customers to choose from

3. Easy to clean: SUS2O1 stainless steel manufacturing, easy to clean

4. Uniform mixing: Fast stirring speed, ensuring consistency of each batch of materials

5. Cost saving: The advantages of small investment, less land occupation, labor saving, and high efficiency

6. Support customization and can be customized according to the actual needs of customers.

Performance parameters of vertical mixer:

1. Suitable for mixing and stirring various plastic raw materials with color masterbatch, with better results when mixing new, old materials and color masterbatch.

2. The spiral conveyor pipe circulates the material from the bottom to the top, making the mixing of raw materials more uniform and fast.

3. The contact surface between the equipment and raw materials is made of 201 stainless steel, which is easy to clean and avoids rust.

4. The equipment is equipped with an electronic safety protection device to ensure safe operation.

Advantages of vertical mixer:

1. Compact structure and space saving: The vertical design makes it occupy a small area and suitable for places with limited space. It can effectively utilize vertical space and facilitate workshop layout planning.

2. High mixing efficiency: The fast rotation of the screw lifts the raw materials from the center to the top of the barrel, and then scatters them in an umbrella shape, returning to the bottom. In this way, the raw materials circulate and mix back and forth in the barrel, and can be evenly mixed in a short time.

3. Convenient operation: The feeding and discharging methods are relatively simple, and some models can be equipped with automatic loading or unloading devices to reduce manual operation intensity. Maintenance is also convenient, and the replacement of vulnerable parts is simple.

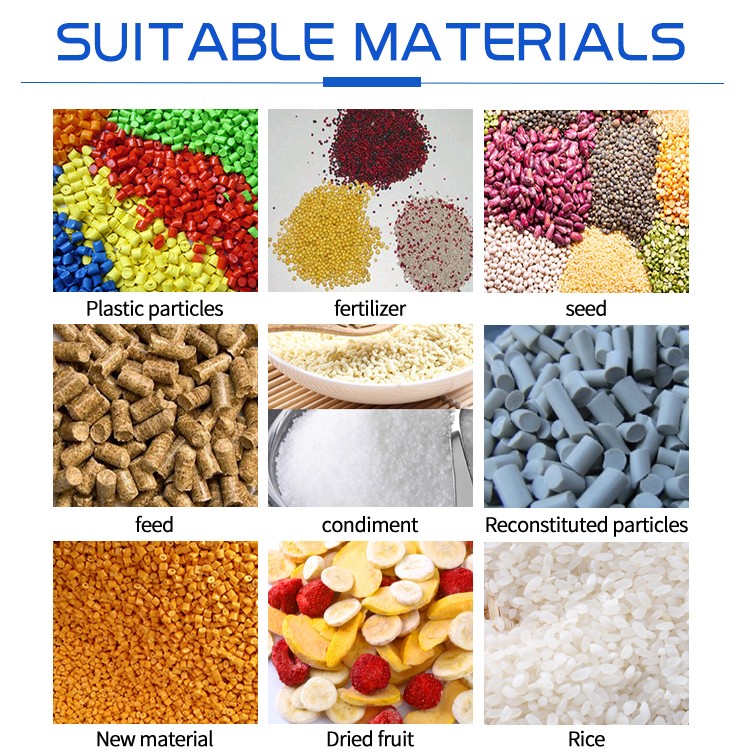

4. Strong adaptability: The mixing blade type can be changed according to different material characteristics (such as granular, powder, paste, etc.) to meet various mixing needs, and is widely used in industries such as chemical, food, and building materials.

5. Good mixing effect: During the mixing process, the material is not easily layered, which can ensure the uniformity and stability of the mixture and improve product quality.