Today, let me introduce how to operate a vertical mixer

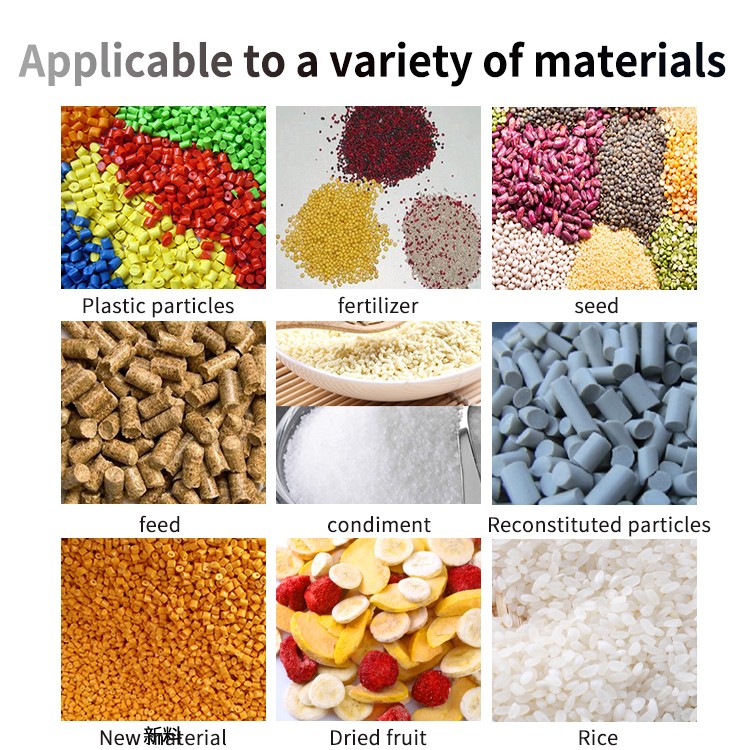

Scope of application of vertical mixer: mainly suitable for PVC particles, PC particles, PP particles, PE particles, TPR particles, dry powder, solid particles, sheet materials, fertilizer mixing, grain mixing, feed mixing, etc. in plastics, chemicals, and agriculture. This device has a beautiful appearance, is simple, corrosion-resistant, acid resistant, sturdy and durable, with low investment and good returns. It is an ideal product suitable for small and medium-sized enterprises or personal investments.

The working principle of a vertical mixer is that the screw rotates rapidly to lift the raw materials from the bottom of the barrel from the center to the top, and then scatter them in an umbrella shape, returning to the bottom. In this way, the raw materials circulate and stir back and forth in the barrel, and can be evenly mixed in a short period of time.

Performance parameters of vertical mixer:

1. Suitable for mixing and stirring various plastic raw materials with color masterbatch, with better results when mixing new, old materials and color masterbatch.

2. The spiral conveyor pipe circulates the material from the bottom to the top, making the mixing of raw materials more uniform and fast.

3. The contact surface between the equipment and raw materials is made of 201 stainless steel, which is easy to clean and avoids rust.

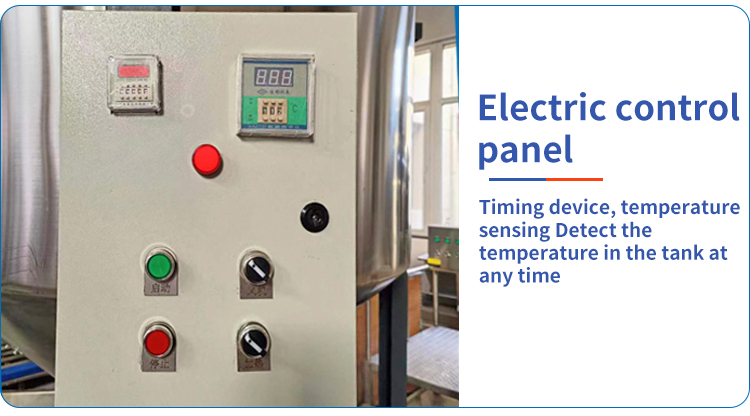

4. The equipment is equipped with an electronic safety protection device to ensure safe operation.

Preparation before using a vertical mixer:

-Equipment inspection: Confirm that all components of the mixer (such as the mixing blade, motor, and protective cover) are securely installed without looseness or damage; Check if the lubricating oil is sufficient and if the oil circuit is unobstructed.

-Environmental cleaning: Clean up the debris around the equipment, ensure spacious operating space, and avoid obstacles affecting operation.

-Material confirmation: Verify the type and ratio of the materials to be mixed to ensure compliance with process requirements and the absence of impurities such as metals and stones in the materials.

Operation steps of vertical mixer

1. Start the device: Connect the power, turn on the control switch, and observe whether the device starts normally, whether there are any abnormal sounds or vibrations.

2. Add materials: After the equipment runs stably, slowly pour the materials into the mixing bucket to avoid overloading caused by excessive feeding at once.

3. Parameter adjustment: Adjust the mixing speed (such as low speed, medium speed, high speed) and mixing time according to the material characteristics and process requirements to ensure uniform mixing of the materials.

4. Operation monitoring: During operation, continuously observe the operation status of the equipment and the mixing of materials. If any abnormalities are found (such as material jamming, abnormal noise, or high temperature), immediately press the emergency stop button to stop the machine for inspection.

5. Shutdown and Unloading: After mixing is complete, turn off the power first, wait for the mixing blade to completely stop rotating, open the unloading port to discharge the material, and clean the residual material in the mixing bucket and mixing blade.

Operation steps of vertical mixer

1. Start the device: Connect the power, turn on the control switch, and observe whether the device starts normally, whether there are any abnormal sounds or vibrations.

2. Adding materials: Slowly pour the materials into the feeding port, being careful not to exceed the middle position of the feeding port to avoid affecting the mixing effect.

3. Set mixing time: Set the corresponding mixing time based on the type of material being mixed.

4. Parameter adjustment: Adjust the mixing speed (such as low speed, medium speed, high speed) and mixing time according to the material characteristics and process requirements to ensure uniform mixing of the materials.

5. Operation monitoring: During operation, continuously observe the operation status of the equipment and the mixing of materials. If any abnormalities are found (such as material jamming, abnormal noise, or high temperature), immediately press the emergency stop button to stop the machine for inspection.

6. Feeding method: Mixing and feeding at the same time can ensure that the materials are evenly mixed during the mixing process, avoiding the phenomenon of layering or clumping of materials in a static state.