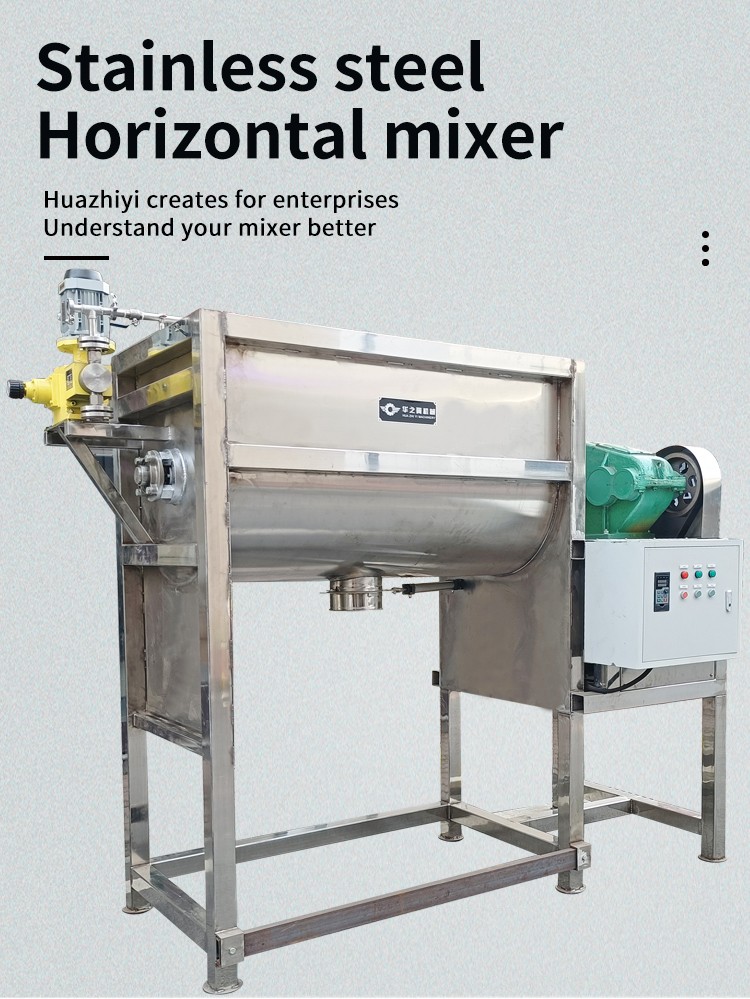

Today, let's talk about the advantages of horizontal mixers

Horizontal mixers are widely used in industries such as feed, chemical, and food. In the feed industry, it is used for mixing animal feed such as pigs, cows, and sheep; In the chemical industry, it is used for mixing various chemical raw materials; In the food industry, it is used for mixing food additives and seasonings.

The working principle of a horizontal mixer is to arrange double-layer spiral blades on the transmission spindle. The internal spiral (small screw belt) transports the material outward, while the external spiral (large screw belt) pushes the material inward. Under the convective motion of the double screw belt, the material forms a low-power and high-efficiency mixing environment. The inner and outer diameter screws installed on the mixing shaft drive the material inside the barrel, allowing the mixer to perform a range of flipping processes on the material inside the barrel. When the mixing device is working, the inner screw drives the material near the axis to rotate around the axis, pushing it from the inside to both sides in the axial direction. The outer screw drives the material near the barrel wall to rotate around the axis, pushing it from both sides to the inside in the axial direction, so that the mixed material can be evenly mixed in a short time.

The advantages of a horizontal mixer include:

1. High mixing uniformity: The mixing blades of the horizontal mixer are usually S-shaped double helix belt type, which can circulate and stir the material along the axial and radial directions, enabling the material to achieve rapid and uniform mixing in a short period of time, with a uniformity of up to 99% or more.

2. High production efficiency: The structural design of the horizontal mixer enables it to process more materials per unit time, and the mixing speed is fast, which can quickly complete the mixing operation and improve production efficiency.

3 . Easy unloading and minimal residue: The discharge port of the horizontal mixer is usually located in the center or lower position at the bottom, and the material can be discharged smoothly under the action of gravity. The unloading speed is fast and clean, with minimal residue.

4. Good operational stability: The center of gravity of the horizontal mixer is lower, making it operate more smoothly with relatively less vibration and noise, especially suitable for long-term continuous operation.

5. Wide applicability: Suitable for mixing various materials, whether they are in powder, granular or viscous form, it can achieve good mixing effect.

6. Low maintenance cost: The structure of the horizontal mixer is relatively simple, with fewer vulnerable parts, and most of the components are easy to disassemble and replace, making maintenance relatively easy and with lower maintenance costs.