Today, let's talk about the types of reaction vessels

Reactors are widely used in industries such as coatings, building materials, pigments, resins, food, and scientific research. It is suitable for mixing and stirring different materials such as shampoo, bath gel, cosmetics water lotion, adhesive, ink, paint, etc.

The heating and cooling methods of the reaction kettle can adopt structures such as jacket, half tube, coil, Miller plate, etc. Heating methods include steam heating, electric heating, and thermal oil heating. Customers can choose according to their actual needs to meet the process requirements of different working environments such as acid resistance, high temperature resistance, wear resistance, and corrosion resistance. And it can be designed and manufactured according to the user's process requirements.

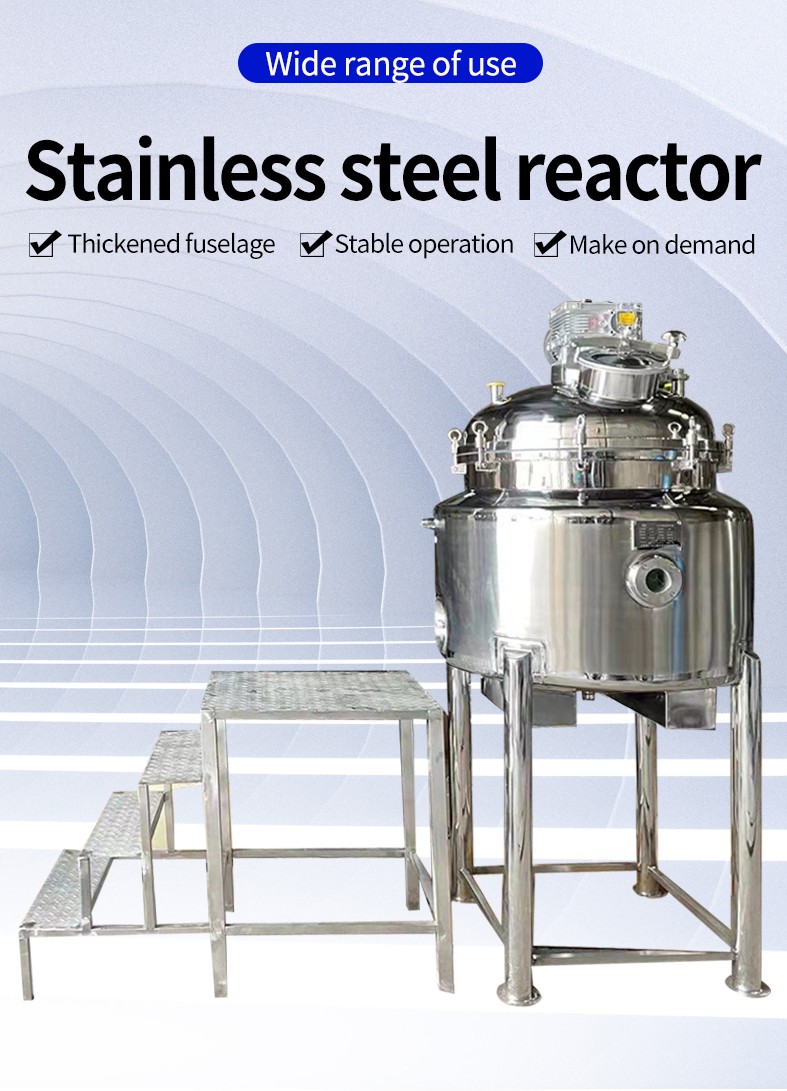

Introduction to stainless steel reaction kettle:

1. The mixing forms generally include paddle type, anchor type, frame type, screw type, scraping wall type, etc.

2. Heating forms include electric heating, oil heating, gas heating, water heating (or cooling), open flame heating, etc.

3. The jacket form is divided into: jacket type and outer half tube type, and the jacket oil heating type is equipped with a guiding device.

4. The mixing methods include low-speed mixing, dispersed impeller type, turbine type, high shear type, and propeller type, for customers to choose according to the process.

5. The sealing methods include ordinary water cooling packing seal, combined PTFE packing seal, and mechanical seal.

6. The discharge methods include manual ball valves, manual butterfly valves, pneumatic valves, electric valves, downward expansion valves, and so on.

Reactors can be divided into different types based on different reaction conditions and the characteristics of reactants, such as atmospheric pressure reactors, high-pressure reactors, vacuum reactors, stirred reactors, etc. Different types of reaction kettles need to be selected based on specific circumstances when used.

The working principle of a reaction kettle is to add reactants to a reaction vessel, and control the temperature, pressure, and stirring speed during the reaction process through a heating/cooling system and a stirring system, causing the reactants to undergo chemical reactions and ultimately obtain the required products.

Characteristics of stainless steel reaction kettle:

1. Stainless steel material has excellent mechanical properties, can withstand high working pressure, and can also withstand the impact of block solid material feeding.

2. It has excellent corrosion resistance and no rusting phenomenon.

3. Good heat resistance, with a wide working temperature range (-196-600 ℃). It does not oxidize and peel at higher temperatures, so it can be used for direct fire heating.

4. The heat transfer effect is better than that of an enamel reactor, with faster heating and cooling rates.

5. It has good processing performance and can be made into reaction kettles of various shapes and structures according to process requirements. The kettle wall can be polished and polished to prevent hanging of materials and facilitate cleaning.