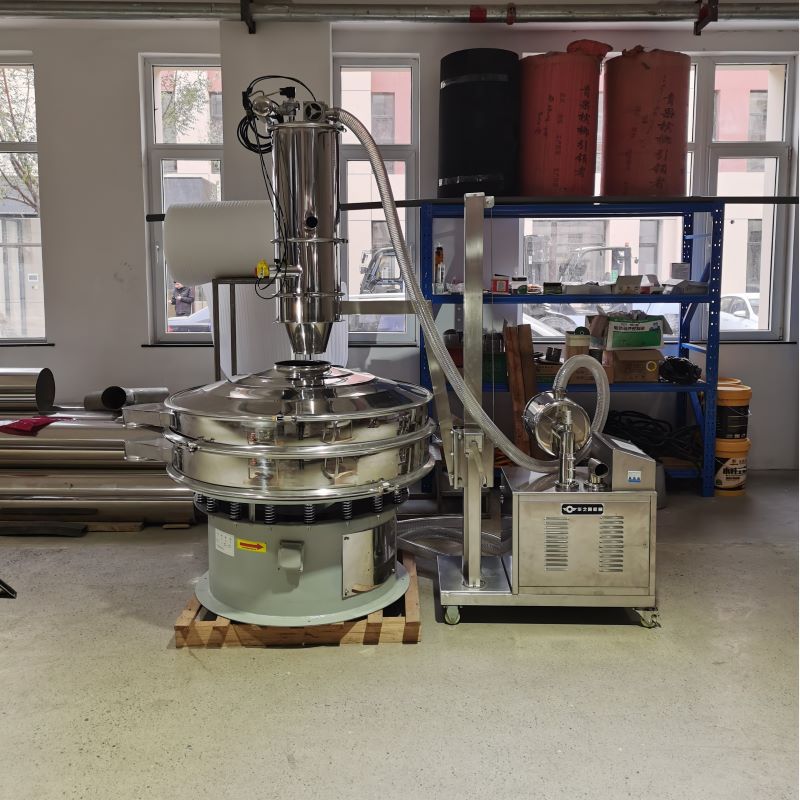

Today, we will introduce a vacuum dust-free feeding machine

Vacuum suction machines come in electric, pneumatic, continuous, mobile hand-operated lifting, and separated designs, among others, which can effectively meet the needs of customers.

A powder suction machine is a dust-free, enclosed pipeline conveying equipment that utilizes vacuum suction to transport granular and powdered materials. It exploits the pressure difference between the vacuum and the ambient environment to create gas flow within the pipeline, which drives the movement of powdered materials, thereby completing the conveyance of the powder.

The vacuum powder suction machine is composed of a vacuum pump, a vacuum hopper, a filter, a compressed air blowback device, a pneumatic discharge valve, a material level automatic control device, a stainless steel suction nozzle, and a conveying hose. It is suitable for vacuum conveying equipment of powdered materials, granular materials, and powder granule mixtures in industries such as food, chemical, and plastic.

Vacuum pump: It is the core component of an electric vacuum feeder, which generates vacuum suction and sucks materials into the conveying pipeline. There are many types of vacuum pumps, and the common ones are rotary blades

Vacuum pumps, reciprocating vacuum pumps, water ring vacuum pumps, etc.

Suction nozzle: It is a component that comes into contact with materials, and its shape and size are designed according to the characteristics and conveying requirements of the materials. The function of the suction nozzle is to suck the material into the conveying pipeline,

And ensure that the materials will not leak during the transportation process.

Conveyor pipeline: It is a component that connects the suction nozzle and the hopper, and its function is to transport materials from the suction nozzle to the hopper. The material of the conveying pipeline is usually stainless steel or carbon steel,

Its diameter and length are designed according to the conveying capacity and distance of the material.

Hopper: It is a component for storing materials, and its shape and size are designed according to the characteristics and conveying requirements of the materials. The function of the hopper is to store materials and ensure that they are transported during transportation

There will be no leakage during the process.

Filter: It is a component installed above the hopper, which filters impurities and dust in the air to ensure the cleanliness of the air entering the vacuum pump. The material of the filter is usually selected

Using stainless steel or polyester film, the filtration accuracy is designed according to the characteristics of the material and the conveying requirements.

Compressed air blowback device: It is a component installed above the filter. Its function is to blow back the filter with compressed air pulses during each discharge, and to remove the adsorbed material from the filter

The surface powder falls off to ensure the normal operation of the suction material.

Pneumatic discharge valve device: It is a component installed below the hopper, and its function is to control the discharge of materials. The pneumatic discharge valve device is usually composed of a cylinder, solenoid valve, and valve master

The body is composed of various components, and its movements are controlled by the control center.

Material level automatic control device: It is a component installed inside the hopper, and its function is to automatically control the conveying amount of materials. The automatic level control device is usually composed of level sensors

Composed of equipment and other components, its actions are controlled by the control center.

The vacuum powder suction machine is composed of a vacuum pump (oil-free, waterless), a vacuum hopper, a filter (with multiple options including polyester film filter, PE filter, 316L stainless steel filter or titanium metal filter), a compressed air blowback device, a pneumatic discharge door device, a material level automatic control device, a stainless steel suction nozzle, a conveying hose, etc

Characteristics of vacuum suction machine equipment:

1. Made of 304/316 stainless steel material, it does not contaminate the powder.

2. Selected vacuum suction pump, working for a long time with low failure rate.

3. Backwash device to avoid air filter blockage and maintenance free.

4. Different materials can be selected, but the feeding machine cannot be configured.

5. The conveying pipeline can be customized as needed Made of materials such as rubber and metal.