Today we introduce a commercial kitchen planetary mixing pot

Planetary stir fry pan is an industrial equipment widely used in the food processing industry, mainly used for baking fillings (such as sauce, lotus seed paste, bean paste, fruit paste, candied fruits, jujube paste, etc.), seasonings (such as hot pot base, instant noodle sauce), as well as mixing and processing candies, vegetable corn products (such as mushroom sauce, peanut butter).

Planetary mixing pot is a mechanical equipment used for mixing, which mainly consists of a pot body, a frame body, a mixing system, a heating system, a speed control transmission device, a mixing shaft, a pot body flipping system, etc.

Planetary mixing pot is a mechanical equipment used for mixing, which mainly consists of a pot body, a frame body, a mixing system, a heating system, a speed control transmission device, a mixing shaft, a pot body flipping system, etc.

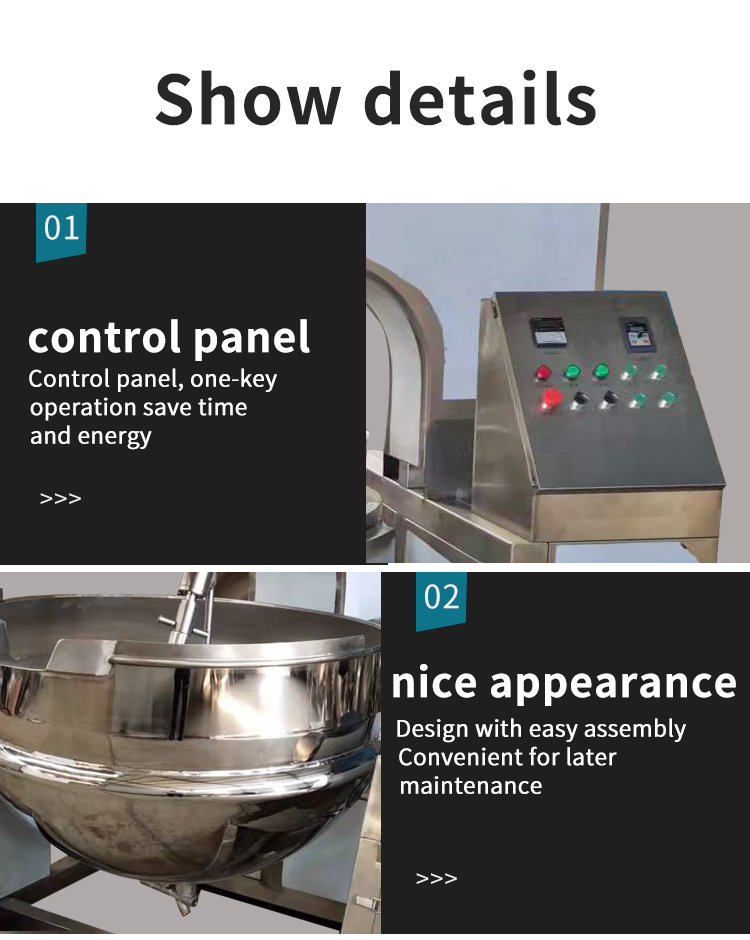

The planetary mixing sandwich pot has the characteristics of easy operation, high work efficiency, low energy consumption, long service life, compact structure, and easy maintenance, making it a high-performance mixer.

The planetary stirring pot adopts a hemispherical stainless steel pot body formed by one-time stamping, and is heated by steam, liquefied gas, natural gas and other heating methods. The stirring method adopts a special inclined transmission, and the planetary stirrer used is in full contact with the pot body, achieving an uneven transmission ratio between the transmission revolution and rotation, so that there are no mixing dead corners in the pot. Using advanced transmission and sealing structures to keep the transmission part and the pot clean and hygienic. Adopting variable frequency speed regulation power for smoother operation. Using hydraulic lifting, flipping the pot to transport materials, without disassembling the mixer, saving manpower and reducing labor intensity, it is a high-performance food processing equipment.

The structure of a mixing pot consists of a pot body, mixing, heating, and transmission devices.

Pot system: Adopting a hemispherical stainless steel pot body or butterfly shaped stainless steel pot body formed by one-time stamping.

Mixing system: The planetary mixer is combined with a scraping bottom mixing system to achieve seamless mixing through an inclined planetary transmission.

Heating system: supports three heating methods: electric heating, gas heating, and steam heating, equipped with an integrated combustion engine and microcomputer control system.

Transmission device: Variable frequency speed control power system, with a large adjustable range of mixing shaft speed.

Main model parameters:

Pot diameter: Φ 1300- Φ 1500 millimeters

Mixing motor power: 3KW

Speed adjustment range: 0-36 revolutions per minute

Turnover form: Fully automatic hydraulic control

Heating method: gas/electromagnetic

Mixing method: planetary/scraping bottom