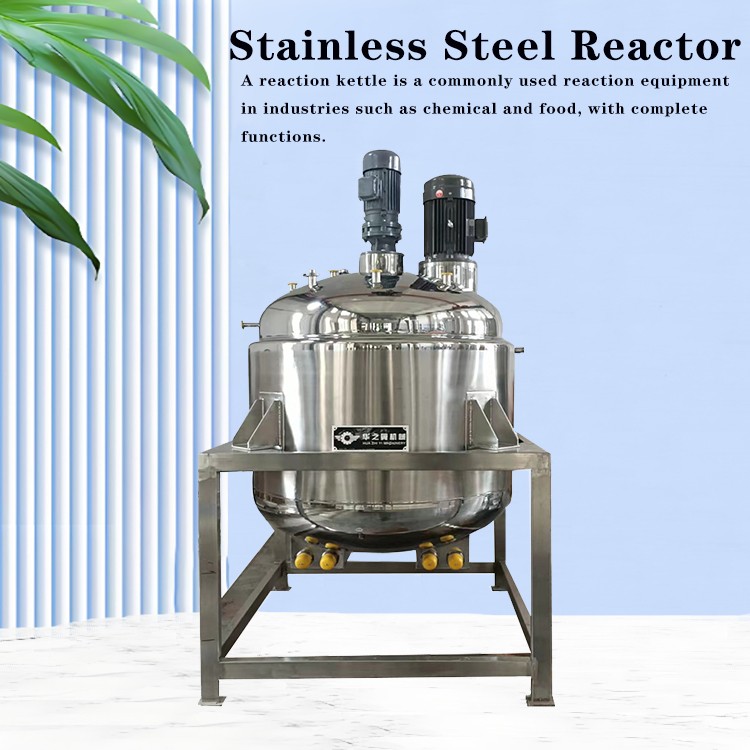

Today, let's talk about how to choose a suitable stainless steel reactor

Stainless steel reaction kettle is widely used Widely applied in industries such as coatings, building materials, chemicals, pigments, resins, food, and scientific research; This device can be selected according to the process requirements of the user's product Made of materials such as carbon steel and stainless steel; And set up heating and cooling devices to achieve full capacity Different processes and production needs; The heating forms include jacket electric heating and coil heating. The equipment has a reasonable structural design and advanced technology Advanced and durable It is easy to operate and convenient to use.

Stainless steel reaction kettle is widely used Widely applied in industries such as coatings, building materials, chemicals, pigments, resins, food, and scientific research; This device can be selected according to the process requirements of the user's product Made of materials such as carbon steel and stainless steel; And set up heating and cooling devices to achieve full capacity Different processes and production needs; The heating forms include jacket electric heating and coil heating. The equipment has a reasonable structural design and advanced technology Advanced and durable It is easy to operate and convenient to use.

Introduction to Reactor Equipment:

1. Material: Made of stainless steel materials such as SUS3O4 and SUS316L.

2. Agitators: anchor type, frame type, paddle type, turbine type, scraper type, dispersing disc type, combination type.

3. Rotating mechanism: cycloidal pinwheel reducer, continuously variable speed reducer or variable frequency speed regulation, etc.

4. Sealing device: mechanical seal, packing seal and other sealing structures.

5. Heating and cooling devices: jacket, half tube, coil, Miller plate, etc.

6. Heating methods include steam, electric heating, and thermal oil.

7. Pressure inside the kettle: normal pressure, positive pressure, negative pressure.

A reaction kettle is a commonly used reaction equipment in industries such as chemical and food, and its advantages are mainly reflected in the following aspects:

-Strong applicability: It can adapt to various reaction conditions, such as high temperature, high pressure, low temperature, vacuum, etc., and can meet the chemical reaction requirements of different materials. For example, it can be used for polymerization reactions in the chemical industry.

-Good mixing effect: Equipped with a stirring device, it can fully mix the materials, improve the reaction rate and uniformity, ensure a more complete reaction, and reduce the generation of by-products.

-High controllability: Through the equipped temperature, pressure, liquid level and other sensors and control systems, various parameters in the reaction process can be accurately regulated to ensure stable reaction and improve the consistency of product quality.

-Good sealing performance: For reactions involving volatile, corrosive, or toxic materials, good sealing performance effectively prevents material leakage, ensuring production safety and environmental friendliness.

-Flexible Capacity: There are multiple specifications of capacity to choose from, ranging from small laboratory reactors to large industrial production equipment, which can meet the production needs of different scales.