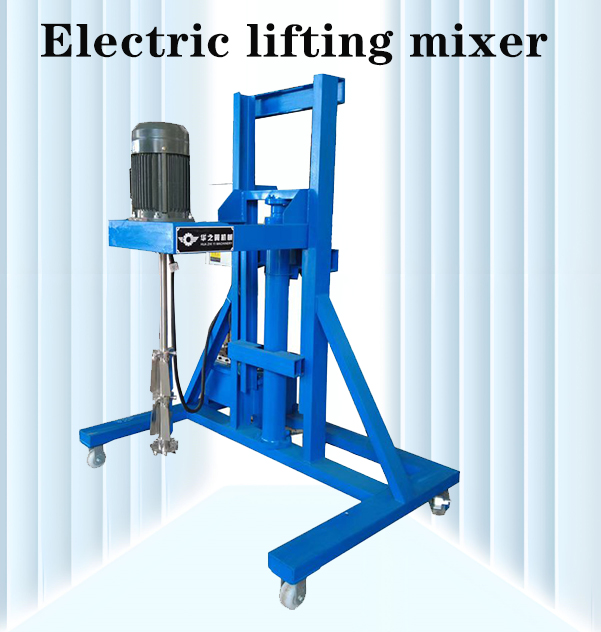

Today, we will introduce an electric lifting mixer

The lifting mixer utilizes the high-speed operation of three bladed and dispersing blades to create a circular flow of material, generating strong vortices that spiral down to the bottom of the vortex. Intense shear impact and friction occur between particles, achieving the functions of rapid dispersion, dissolution, uniform mixing, and emulsification.

IBC mixers are suitable for industries such as chemical, food, coatings, water treatment, and new energy that require mixing and stirring of large volume materials.

-Chemical industry: Mixing and dispersing various chemical raw materials, intermediates, solvents, resins, etc., such as coatings, adhesives, inks, etc.

-Food industry: Mixed food raw materials, sauces, beverage concentrates, additive solutions, etc. must meet food grade material requirements (such as stainless steel 304/316).

-Coatings and building materials industry: mixing latex paint, waterproof coating, putty powder slurry, building materials additives, etc., to solve the problems of material sedimentation and uneven dispersion.

-Water treatment industry: mixed wastewater treatment, circulating water quality regulators, etc.

-New energy industry: Mixing lithium battery positive and negative electrode slurries, electrolytes, photovoltaic material precursors, etc. to ensure material uniformity.

-Agricultural industry: mixing pesticide diluents, fertilizer solutions, feed additives, etc.

The core advantages of the electric lifting IBC mixer are:

1. Adaptability and universality: Designed specifically for IBC ton drums, without the need for container modification, it can directly adapt to standard specification ton drums such as 200L-1000L, suitable for liquid and paste mixing scenarios in multiple industries such as chemical, food, and pharmaceutical.

2. Convenient and efficient operation: The electric lifting system replaces manual handling and only requires button control of the lifting and positioning of the mixing shaft, greatly saving manpower and reducing operation intensity, especially suitable for high-frequency and large-scale mixing operations.

3. Stable mixing effect: The length and speed of the mixing shaft can be adjusted according to the characteristics of the material (such as viscosity and solid content), combined with customized propeller blades (such as push type and anchor type), to achieve uniform mixing of the materials in the bucket, avoiding local sedimentation or stratification.

4. Safety and durability: Some models are equipped with overload protection, limit switches, and other safety devices to prevent equipment damage caused by excessive load or lifting over travel; The body is mostly made of stainless steel or anti-corrosion materials, which are suitable for corrosive material environments and extend the service life.

5. Strong flexibility: Supports fixed installation or mobile base design, and can flexibly adjust the usage position according to the production layout, taking into account the needs of single barrel operation and assembly line integration.