The introduction of the new conveyor product U-shaped feeder in 2022

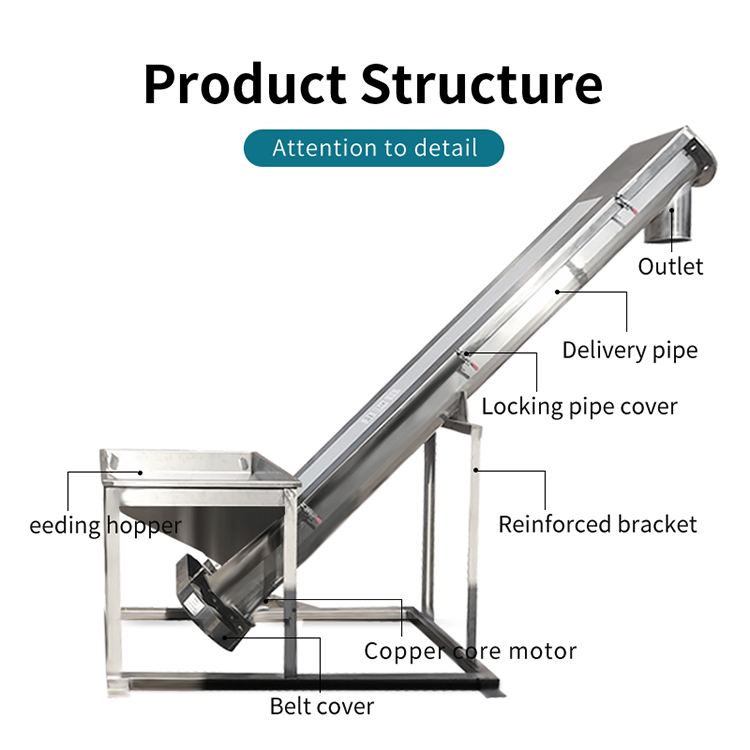

The U-type screw conveyor is designed and manufactured according to the JB/T679-95 "Screw Conveyor" standard, and it is the replacement product of the GX-type screw conveyor. The screw conveyor, commonly known as the auger, is a kind of conveying equipment widely used in the mining, feed, grain and oil, and construction industries. From the perspective of the displacement direction of the conveyed materials, the screw conveyor is divided into a horizontal screw conveyor and a vertical screw conveyor. There are two types of machines, which are mainly used for horizontal conveying and vertical lifting of various powder, granular and small pieces of loose materials. The screw conveyor is all made of steel, and the screw conveyor is used to transport chemical and building materials products such as powder or solid particles with high temperature. There is a conveying pipe inside the screw conveyor, and the blades are spirally welded on the conveying pipe.

Main features of U-shaped screw conveyor:

1. Large and reliable bearing capacity.

2. Strong adaptability, convenient installation and maintenance, and long service life.

3. The whole machine is small in size and high in rotation speed to ensure fast and even delivery.

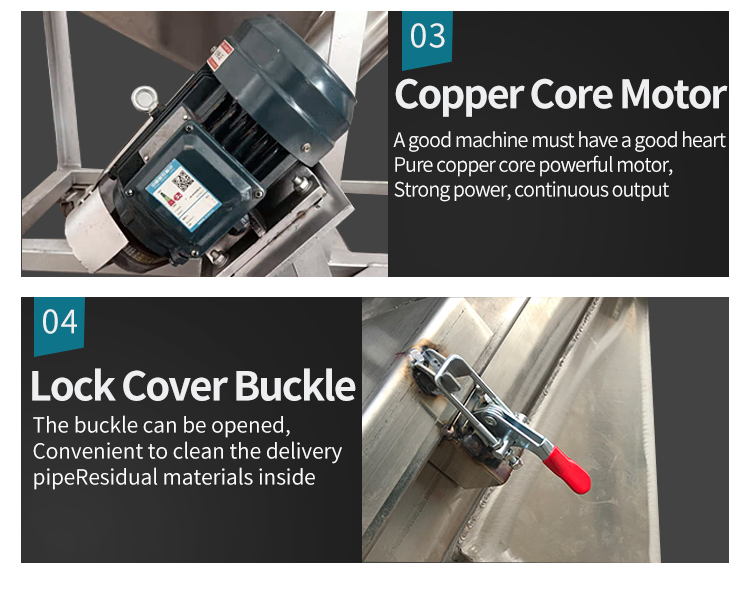

4. The discharge end is equipped with a cleaning device, the whole machine has low noise and strong adaptability, and the position of the inlet and outlet is flexible.

5. Good sealing, the shell is made of seamless steel pipe, and the ends are connected with each other by flanges, which has good rigidity.

Application scope of screw conveyor:

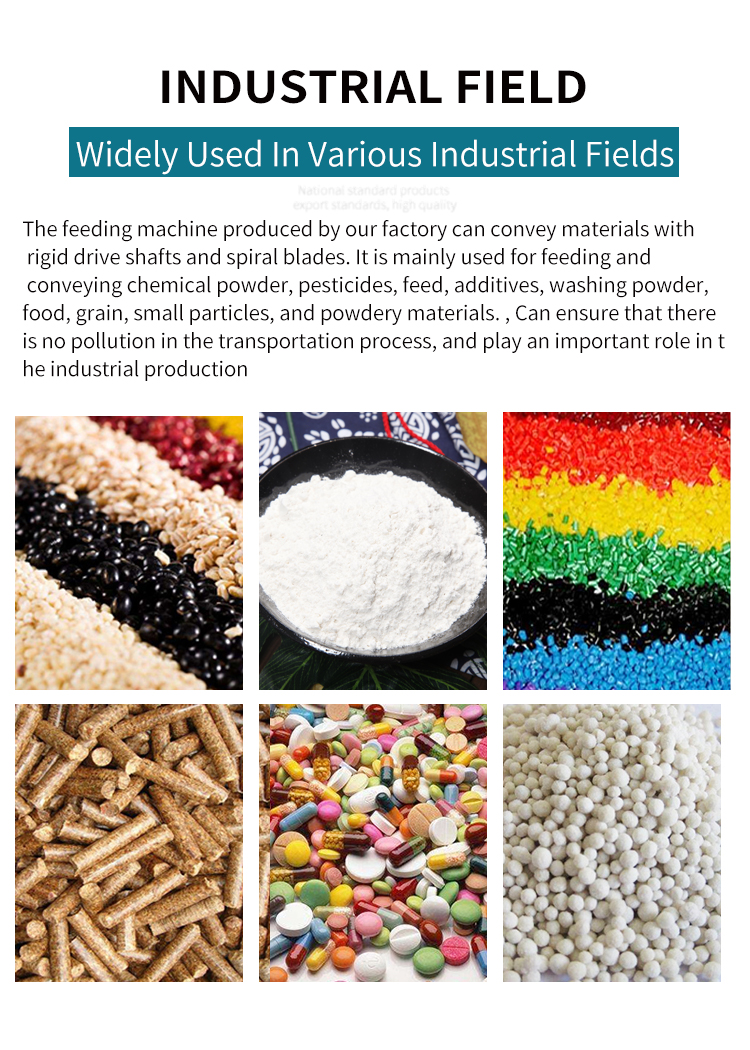

Screw conveyors have been widely used in various sectors of the national economy, such as building materials, metallurgy, chemical industry, electric power, coal, machinery, light industry, grain and food industries, suitable for conveying powdery, granular and small block materials, such as cement, Coal powder, grain, fertilizer, ash, sand, coke, etc. It is not suitable to transport materials that are easily deteriorated, viscous, and easy to agglomerate. -20~80℃, LS screw conveyor is suitable for horizontal and small inclination arrangement, the inclination angle should not exceed 15°, if the inclination angle is too large, please use GX series screw conveyor.

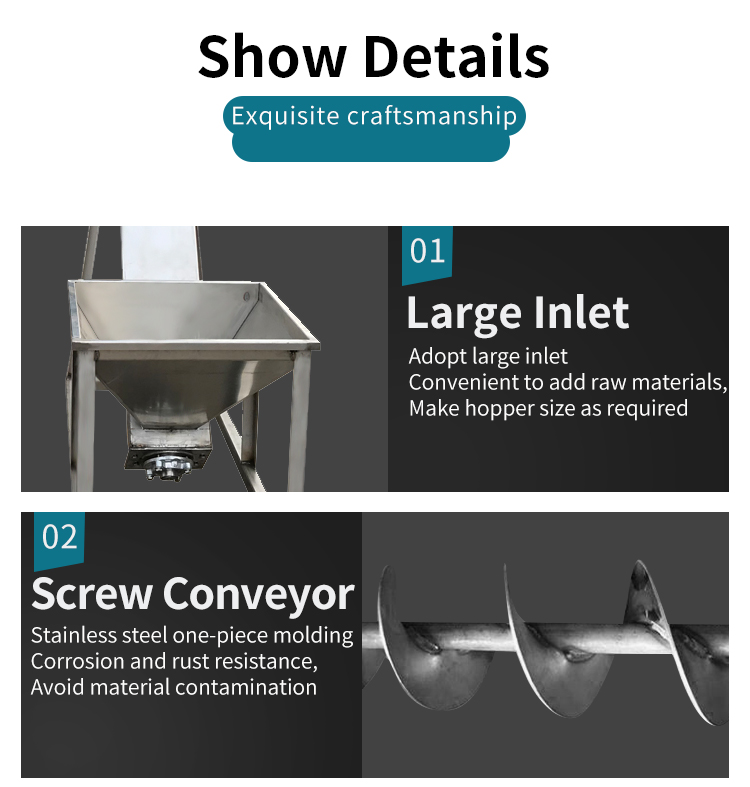

The U-shaped trough screw conveyor is an ideal conveying equipment for bulk powder materials. It provides closed transportation and can prevent powder materials from overflowing. The U-shaped trough screw conveyor can add materials from one or more inlets, which is very convenient to use. The U-shaped trough screw conveyor can transport materials both horizontally and obliquely. When space allows, it is a very economical lifting and conveying equipment, but as the inclination angle increases, the conveying capacity will decrease.

Six specifications of U-groove screw conveyor: screw diameter: LX220, LX250, LX300, LX350, LX400.

Six standard revolutions (number/min): 35, 45, 75, 95, 120, 140

Length of screw machine: from 0.5 meters to 15 meters, the conveying length can be freely selected

Features of U-shaped screw conveyor:

1. The U-shaped trough screw conveyor has the advantages of high power, low energy consumption, small volume and no floor space.

2. Strong conveying capacity, stable conveying, even conveying material, not easy to jam

3. Convenient maintenance, easy maintenance, low failure rate

4. It belongs to environmental protection equipment, because it will not cause dust during material transportation, will not pollute the surrounding environment, and has good sealing performance

Application: Mainly used for horizontal or small angle (0-15°) conveying. It can be divided into axial spiral and non-axial spiral.

Matters needing attention when purchasing inclined tubular screw conveyor:

1. Materials to be conveyed: it is better that the specific gravity of dry powder materials should not be too heavy

2. Inclination angle: 0-60°

3. Conveying length: the larger the inclination angle is, the conveying length should not be too long;

4. Motor power: Determine the motor power to be selected according to the conveying length, inclination angle, and conveying amount, choose large or small;

5. Spiral rotation speed: The rotation speed of the screw conveyor is selected according to the inclination angle of the specification model. The larger the inclination angle, the faster the rotation speed.