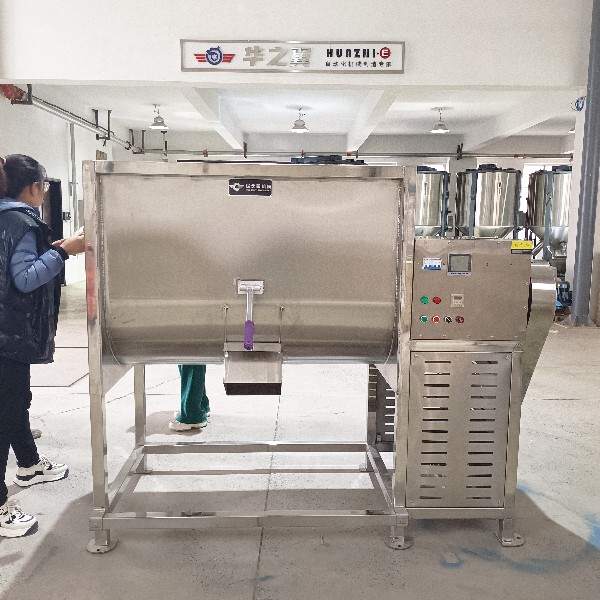

Today we will introduce a mixer with spiral discharge

Horizontal mixers are widely used for material mixing in industries such as chemical, food, compound fertilizers, dyes, pigments, rubber, building materials, diatomaceous earth mud, refractory materials, rare earths, plastic glass, as well as new materials, nuclear energy materials, etc., for solid solid (i.e. powder to powder) and solid slurry (i.e. powder to slurry) mixing.

The horizontal mixer has good mixing effect: the horizontal barrel body is matched with internal mixing blades (such as screw belts and blades), which can allow the material to fully flow and shear inside the barrel, especially suitable for powder and granular materials, and the mixing uniformity is much higher than that of the vertical mixer.

Horizontal mixer with spiral discharge for high efficiency and residue free: The spiral discharge structure can be driven by a motor to quickly and continuously transport the mixed materials to the next stage (such as a silo or packaging machine), and the spiral can be designed to fit the bottom of the bucket, greatly reducing the residual amount of materials in the bucket.

Easy cleaning and maintenance: Some models' mixing drums or spiral components can be disassembled and cleaned, with smooth inner walls, reducing material adhesion and difficulty in cleaning. At the same time, the spiral structure has a low failure rate and relatively controllable maintenance costs.

The working principle of the horizontal mixer with spiral discharge can be divided into two core stages: material mixing and spiral discharge. The whole process is completed by the cooperation of different components driven by a motor:

1. Material mixing stage

-After the material enters the horizontal mixing drum through the feeding port, the motor drives the mixing components (usually screws, blades, or mixing rods) inside the drum to rotate at high speed.

-The mixing component disperses and mixes different types and states of materials (such as powders and particles) in the bucket through shearing, convection, flipping, and other actions until the uniformity requirements are met. During this process, the horizontal bucket design can reduce mixing dead corners and ensure the mixing effect.

2. Spiral discharge stage

-After mixing is completed, turn on the spiral conveyor motor at the discharge port to drive the spiral blades at the bottom (or discharge end) of the barrel to rotate.

-The spiral blades generate propulsion force through rotation, continuously and stably pushing the uniformly mixed materials along the spiral groove towards the discharge port, and finally conveying them to the next production process (such as material bin, packaging machine), and the design of the fit between the spiral and the barrel wall can minimize material residue.