How to choose the right powder packaging machine

Which powder packaging machine manufacturer is good? Compared with traditional packaging machines, the operation of powder packaging machines in the production process is simpler, easy to use, and improves labor productivity. Many manufacturers have chosen powder packaging machines, so powder packaging machines are used in a wider and wider range. The question that everyone is most concerned about is which powder packaging machine is better, so let the packaging machine editor introduce it to you.

At present, the automatic speed of powder packaging machines has been unprecedentedly improved, and one machine can at least exceed the packaging efficiency of eight ordinary workers. The salary of 8 workers is actually a lot of expense, but if you use a powder packing machine, you only need two operators to get the job done. Moreover, the operation of the powder packaging machine is very simple and easy to learn

The powder packaging machine not only has high stability, but also has a very low error rate, which is about three thousandths. In the packaging process, there are very few errors, so a large number of substandard products will be produced, which will greatly increase the cost while wasting time and materials.

To sum up the above points, we can rationally judge whether the powder packaging machine is expensive or not?

The price of powder packaging machines is about 20,000 to 40,000 yuan, but purchasing powder packaging machines should not only look at the price, but also consider comprehensively. Long hair packaging service company has 20 years of experience in the packaging industry and has perfect after-sales service. The powder packaging machines they produce are stable in performance, easy to operate, and can also be customized according to needs.

The packaging range of dry powder packaging machine is 20G-5KG, 5KG-50KG and other specifications and models. Customers need to provide packaging and transportation. We recommend suitable packaging machines for you. At the same time, our company also produces sealing machines, powder feeding machines and other supporting equipment

a) Packing specification: 20g-5000g

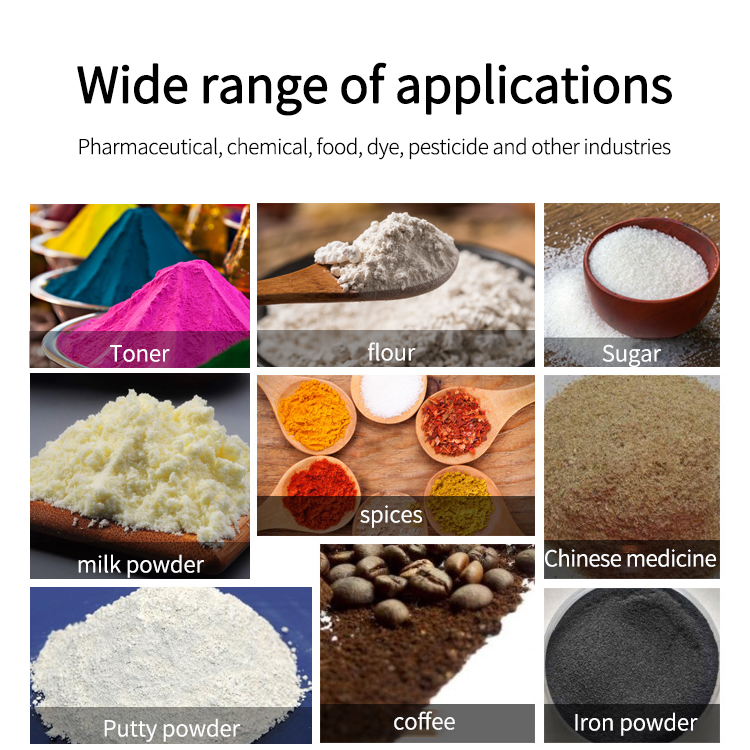

b) Applicable materials: powder

c) Packaging error: ±0.5-1% (depending on material and weight)

d) Material particle size: 50~500 mesh

e) Packing speed: 10~25 bags/min

f) Torque: 10 N/M

g) Speed: 1500 rpm,

h) Torque/Speed: No change

i) Appearance length, width and height: 850*850*1950

j) Host power: 0.9kw

Computer quantitative packaging machine is mainly composed of host, computer controller, electronic scale and other parts. The main machine adopts screw metering and stepper motor to control the blanking.

This set of equipment is especially suitable for fine powder materials such as (chicken powder, milk powder, soybean powder, five-spice powder, flour, curry powder, garlic powder, baking powder, chili meat powder, corn flour, milk tea powder, glutinous rice flour, sesame aleurone powder, Nutritious rice flour, baby rice flour, sticky rice flour, starch, cinnamon powder, pepper powder, Chinese yam powder, garlic powder and corn soup stock, Chinese pepper powder, cornstarch beef powder, pork ribs powder, custard powder, sweet potato powder, wheat flour cake powder , cake flour, jelly bean flour, black pepper powder, Orleans roast chicken powder, star anise powder, hot pot ingredients, hot pot base, thirteen spice powder, rice ball powder)

1. Microcomputer measurement, touch screen control, accurate quantitative. Parameters can be adjusted and errors can be automatically corrected;

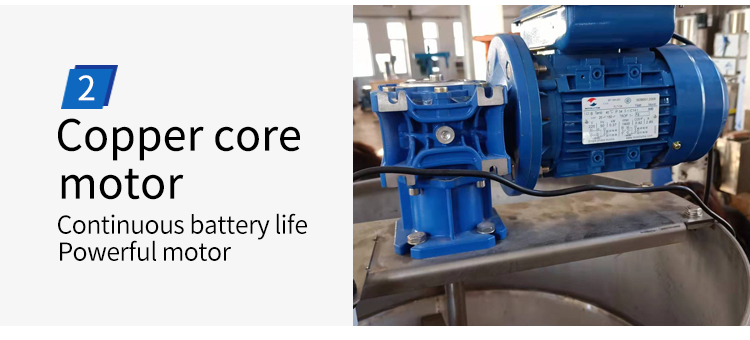

2. Stepper motor replaces electronic clutch, no wear, non-contact, maintenance-free, and low failure rate;

3. Rolling bearing replaces sliding bearing with less wear and tear. The strong and weak electricity are separated, and there is no interference. High reliability and wide application;

4. The filling parts have high machining accuracy, good interchangeability and reasonable grading;

5. Modular design, flexible combination. Automatic feeding device, bagging device and leak-proof device can be selected as required.