Today we will introduce a screw belt mixer

Horizontal mixers are widely used for mixing materials in industries such as chemical, food, compound fertilizers, dyes, pigments, rubber, building materials, diatomaceous mud, refractory materials, rare earths, plastic glass, and new materials, such as solid to solid (i.e. powder to powder) and solid to slurry (i.e. powder to slurry).The horizontal mixer can be made of carbon steel and stainless steel material, used for stirring and mixing dry powder. It is mostly used for mixing two or more types of powder, and mixing evenly.

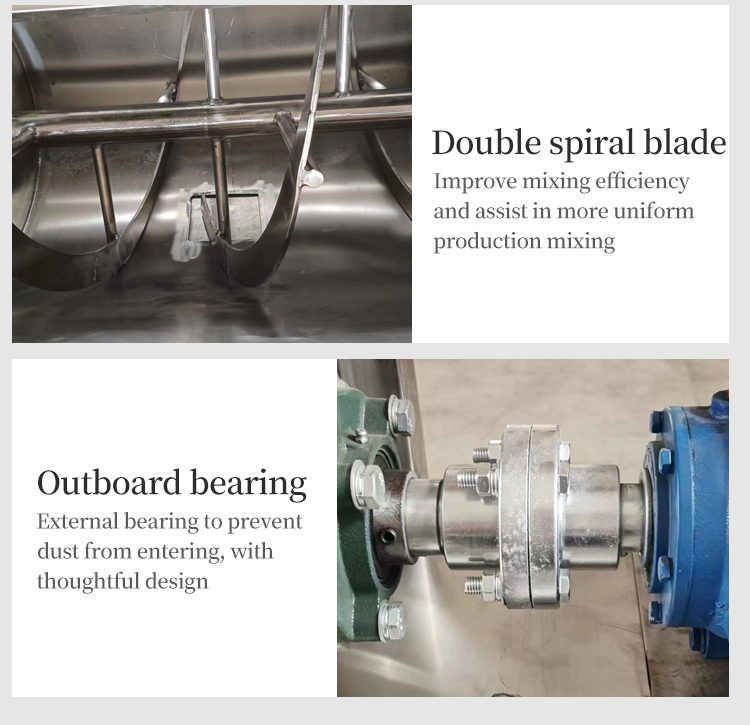

The working principle of a horizontal mixer is to arrange double-layer spiral blades on the transmission spindle, with internal and external spirals (small spiral belts) conveying materials to the outside, and external spirals (large spiral belts) pushing materials inward. Under the convective motion of the double spiral belts, the materials form a low power and high efficiency mixed environment. The inner and outer diameter screws installed on the mixing shaft drive the material inside the barrel, causing the agitator to flip the material within a certain range inside the barrel. When the mixing device is working, the inner screw drives the material near the axis to rotate axially, pushing it from the inside to both sides. The outer screw drives the material near the barrel wall to rotate axially, pushing it from both sides to the inside, allowing the mixed material to mix evenly in a short period of time.

Introduction to horizontal mixer:

1. Material: Made of stainless steel such as carbon steel, SUS201, SUS304, SUS316L, etc., divided into material contact surfaces made of stainless steel or customized whole machine stainless steel materials.

2. There are multiple models of mixing capacity available, with specifications ranging from 100-10000L for customers to choose from.

3. The interior of the barrel is polished smooth, and the blades are stirred without dead corners. Each batch can be mixed evenly in 5-15 minutes.

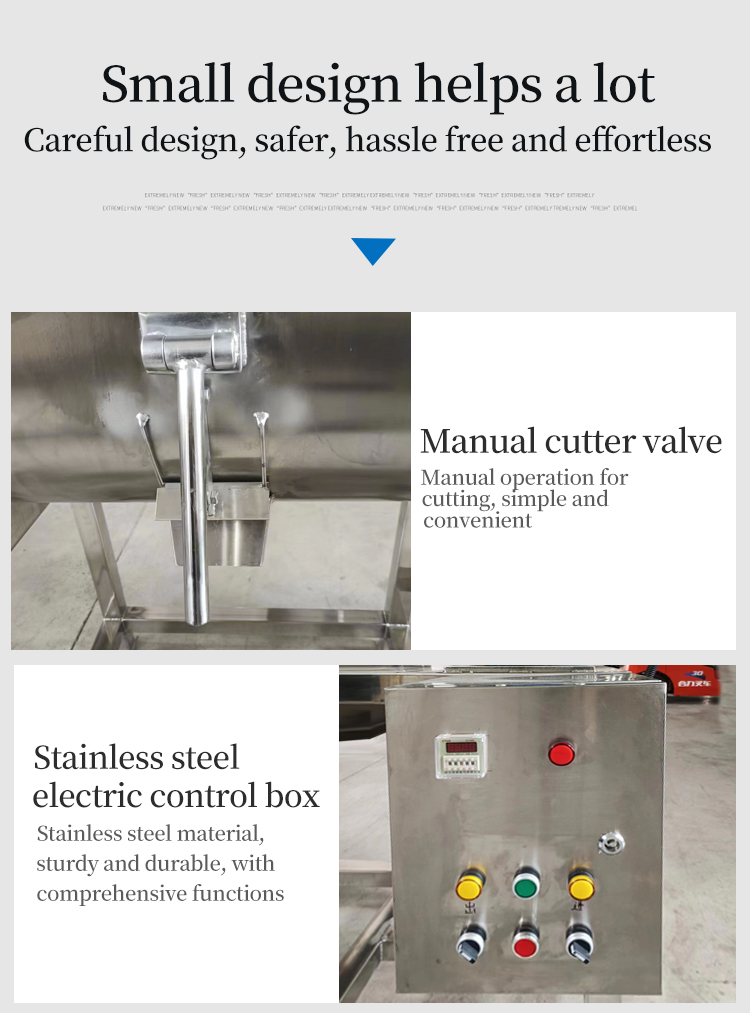

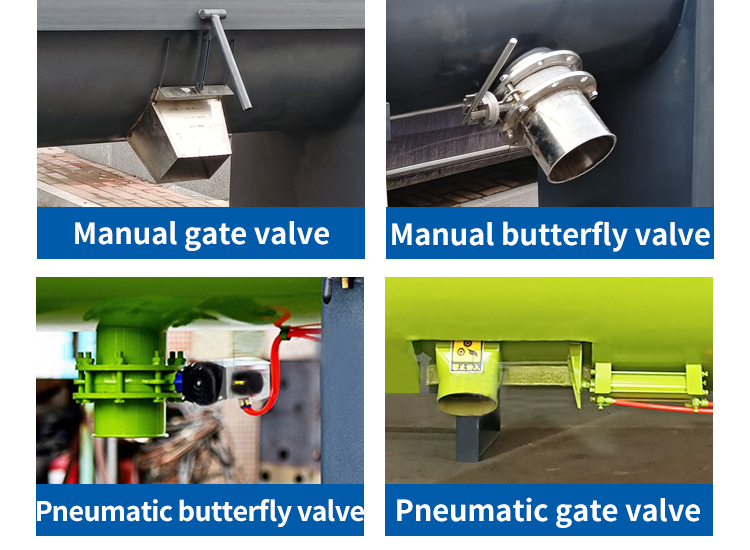

4. The all stainless steel center shaft and single or double "S" - shaped blades enable rapid and uniform mixing of materials. 5. The discharge outlet has manual knife type, wall mounted, manual butterfly valve, pneumatic butterfly valve, and dust-proof and leak proof. 2>

6. The motor adopts a fully copper wire motor and a cycloidal pinwheel reducer, which has a long service life, low noise, and high torque.

7. In addition, our company has supporting equipment such as spiral feeding machines, vacuum suction machines, and conveyor belts, which can reduce labor intensity and save time and labor by eliminating the feeding platform.