Is the three-legged vegetable dehydrator easy to use?

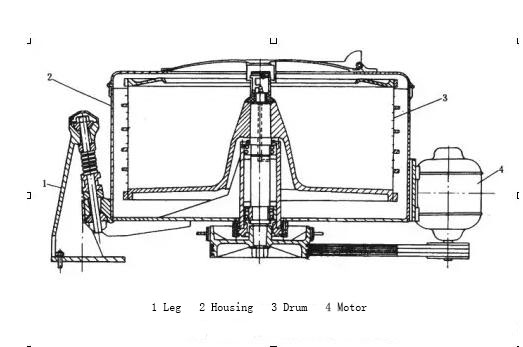

The three-legged centrifugal dehydrator is a typical batch filter centrifuge, which can feed continuously, but needs to be shut down to discharge slag after a period of time. The shape and structure of the three-legged centrifuge for manual slag discharge are shown in Figure 4-15. The drum, also known as the filter basket, is made of stainless steel, and the drum wall has filter holes. The drum is driven by a motor through a pulley drive. The characteristic of this machine is that the shell, drum and transmission are all suspended and fixed on three pillars by means of damping spring assemblies (so it is called a three-legged centrifuge) to reduce the vibration generated when the centrifuge drum is running.

Three-legged vegetable dehydrator

During operation, the slurry to be separated is injected into the rotating drum (covered with filter cloth in advance) through the feeding pipe set on the centrifuge, and the liquid is subjected to centrifugal force and then passes through the filter cloth and the small holes on the wall and is thrown away. out, and it flows out from the lower liquid outlet after being collected in the casing. The solid materials that cannot pass are trapped on the filter cloth to form a filter cake layer. When the filter cake layer reaches a certain thickness, stop the machine to remove the slag, and take out the solid filter cake layer from the centrifuge together with the filter cloth bag manually. The three-legged centrifuge is suitable for materials that are not large in volume but require adequate washing. In order to make the material evenly distributed in the drum and avoid the load eccentricity, it is advisable to use low-speed feeding, high-speed filtration, dehydration, speed reduction or shutdown for unloading. The main advantages of the three-legged centrifuge are: strong adaptability to materials, the operating conditions of filtration and washing can be adjusted at any time as needed, sufficient washing can be performed to obtain a relatively dry filter residue, the solid particles are hardly damaged, and the operation Stable, simple structure and low cost. The disadvantages are intermittent operation, long auxiliary operation time, low production capacity and high labor intensity. The three-legged centrifuge is widely used in the food industry such as the separation of crystallization and mother liquor in the production of monosodium glutamate, citric acid and other organic acids.

During operation, the slurry to be separated is injected into the rotating drum (covered with filter cloth in advance) through the feeding pipe set on the centrifuge, and the liquid is subjected to centrifugal force and then passes through the filter cloth and the small holes on the wall and is thrown away. out, and it flows out from the lower liquid outlet after being collected in the casing. The solid materials that cannot pass are trapped on the filter cloth to form a filter cake layer. When the filter cake layer reaches a certain thickness, stop the machine to remove the slag, and take out the solid filter cake layer from the centrifuge together with the filter cloth bag manually. The three-legged centrifuge is suitable for materials that are not large in volume but require adequate washing. In order to make the material evenly distributed in the drum and avoid the load eccentricity, it is advisable to use low-speed feeding, high-speed filtration, dehydration, speed reduction or shutdown for unloading. The main advantages of the three-legged centrifuge are: strong adaptability to materials, the operating conditions of filtration and washing can be adjusted at any time as needed, sufficient washing can be performed to obtain a relatively dry filter residue, the solid particles are hardly damaged, and the operation Stable, simple structure and low cost. The disadvantages are intermittent operation, long auxiliary operation time, low production capacity and high labor intensity. The three-legged centrifuge is widely used in the food industry such as the separation of crystallization and mother liquor in the production of monosodium glutamate, citric acid and other organic acids.