Equipment for making peanut butter-introduction, installation and maintenance of colloid mill

Working principle of colloid mill:

Colloid mill is made by the motor through the belt transmission belt rotating teeth and matching fixed teeth for relatively high speed rotation, one high-speed rotation, the other static, by the production material through its own weight or external pressure (can be produced by the pump) pressure to produce downward spiral impact force. Through the clearance between fixed and rotating teeth (the clearance is adjustable), the material is emulsified, dispersed, homogenized and crushed effectively, so as to achieve the effect of fine crushing and emulsification of materials.

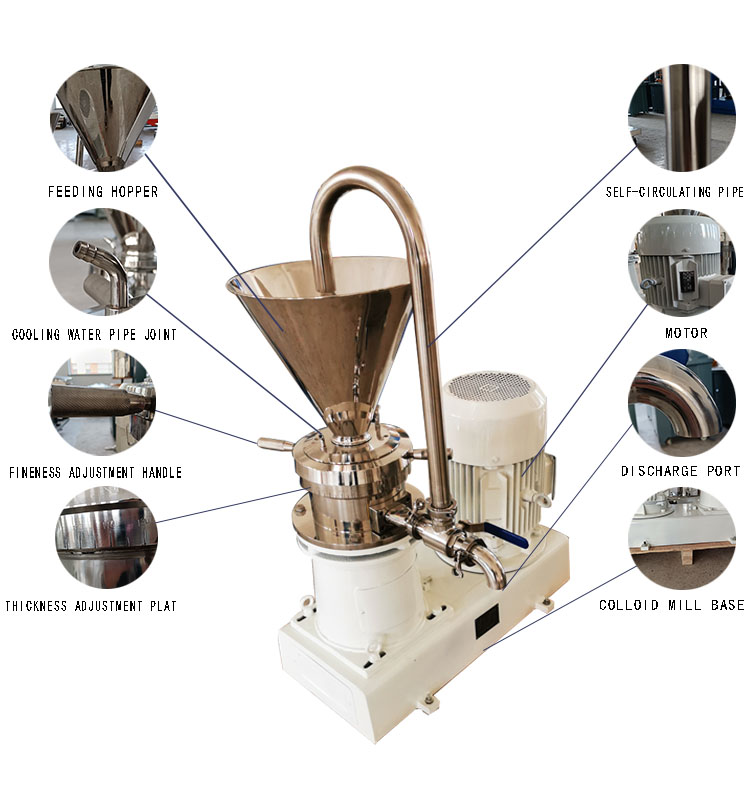

Structure:

Colloid mill has a number of patented products: compact design, utility model, beautiful appearance, good sealing, stable performance, convenient operation, simple decoration, durable, wide range of adaptation, high production efficiency, is the most ideal processing equipment for handling fine materials. In addition to the motor and some parts of the colloid mill products, all the parts in contact with the material are made of high strength stainless steel. In particular, the key dynamic and static grinding plate is strengthened. Therefore, it has good corrosion resistance and wear resistance, so that the processed materials are pollution-free and pure.

Processing state: multistage online emulsifying and dispersing machine

Function: online dispersion emulsification health care

Features:

1. Three-stage online dispersion emulsifier

2. Three stage fixed rotor form: 2G (coarse) 4M (medium) 6F (fine)

3. Perfect choice for stable homogeneous emulsion and suspension

4. Scattered head can be freely assembled, modular and easy to maintain

5. Centralized particle size distribution can be obtained with only one treatment

6. Stepless speed regulation (inverter)

7. All contact materials are made of SS316

8. Meet CIP/SIP cleaning standards, suitable for food and pharmaceutical production

Requirements of colloid mill for materials:

Can not grind dry solid materials, only wet grinding. Material grinding should be removed before debris, material particle size is less than 1㎜, material hardness shall not be higher than HV309, iron and gravel particles and other hard objects into the grinding head, to prevent damage to the machine.

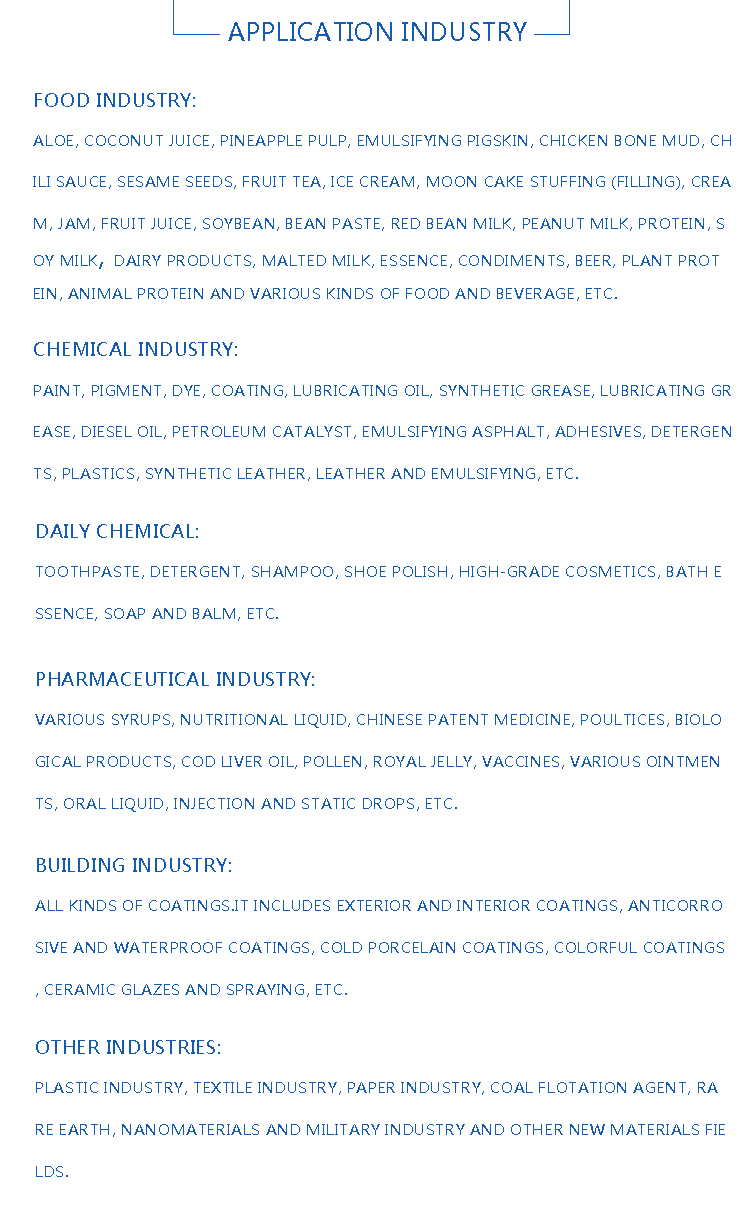

Application scope:

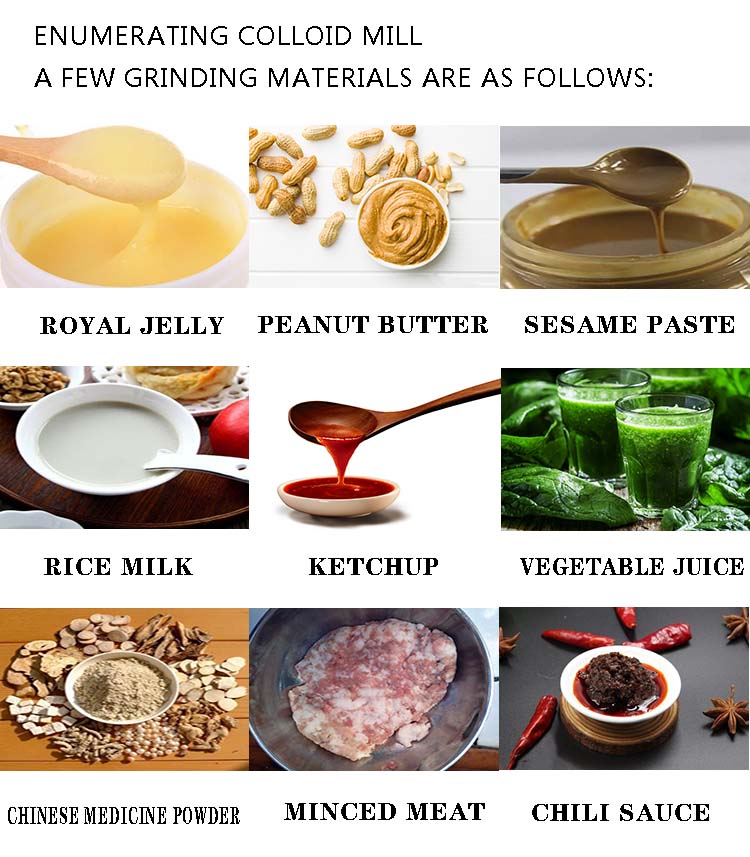

1, food industry: aloe vera, pineapple, sesame, fruit tea, ice cream, moon cake stuffing, cream, jam, fruit juice, soybeans, bean sauce, bean paste, peanut milk, protein milk, soy milk, dairy products, malted milk, essence, all kinds of drinks, etc.

2, chemical industry: paint, pigments, dyes, coatings, lubricating oil, grease, diesel oil, petroleum catalyst, emulsified asphalt, adhesives, detergent, plastic, FRP, leather, emulsification, etc.

3, daily chemical: toothpaste, detergent, shampoo, shoe polish, advanced cosmetics, bath essence, soap, balm, etc.

4, the pharmaceutical industry: all types of syrup, nutritional liquid, Chinese patent medicine, cream, biological products, cod liver oil, pollen, royal jelly, vaccines, all kinds of otions, all kinds of oral liquid, injection, drip, etc..

5, construction industry: all kinds of coatings. Including interior and exterior wall coating, anti-corrosion and waterproof coating, cold porcelain coating, colorful coating, ceramic glaze, etc.

6, other industries: plastic industry, textile industry, paper industry, coal flotation agent, nanomaterials and other industries high-quality environmental production needs

Colloid mill installation:

1. The equipment is installed horizontally on a flat concrete foundation and fixed with anchor screws (it may not be fixed according to the working situation).

2. Check whether all screws are tightened (M12 left-rotation screws in the center of the rotor).

3. Before use, rotate the rotor with a special wrench to check whether it is in contact with the stator and whether it is stuck. In such cases, it is not allowed to start.

4. Check and connect the power cables (three-phase AC, 380 V, body protection grounding) and ensure that the rotor rotates in the same direction as the arrow on the base (clockwise).

5. Connect the cooling water, and pay attention to the inlet and outlet water mark of the nozzle.

6. Start the motor, first switch, check whether there is noise, vibration. If the situation is abnormal, it should be stopped immediately and then run again after troubleshooting.

Maintenance and maintenance:

(1) Check whether the colloid mill pipes and joints are loose. Turn the colloid mill by hand to see if it is flexible.

(2) Add bearing lubricating oil to the bearing body, observe the oil level should be at the center line of the oil mark, and the lubricating oil should be replaced or supplemented in time.

(3) unscrew the water diversion plug of the colloid mill pump body, and pour water diversion (or slurry).

(4) Close the gate valve of the outlet pipeline, the outlet pressure gauge and the inlet vacuum gauge.

(5) point the motor, and check whether the motor turns correctly.

(6) Start the motor, when the colloid mill is in normal operation, open the outlet pressure gauge and the inlet vacuum pump to see that the appropriate pressure is displayed, gradually open the gate valve, and check the motor load.

(7) try to control the flow and head of the colloid mill within the range indicated on the sign, in order to ensure that the colloid mill operates at the highest efficiency point, in order to obtain the maximum energy saving effect.

(8) During the operation of the colloid mill, the bearing temperature cannot exceed the ambient temperature of 35C, and the highest temperature shall not exceed 80C.

(9) If any abnormal sound is found, stop the colloid mill immediately to check the reason.

(10) When the colloid mill is to stop using, close the gate valve and pressure gauge first, and then stop the motor.

(11) Colloid mill in the first month of work, after 100 hours to replace the lubricating oil, after every 500 hours, oil change once.

(12) Regularly adjust the packing gland to ensure that the dripping situation in the packing room is normal (it is advisable to drip out).

(13) Check the wear of the shaft sleeve regularly, and replace it in time after the wear is large.

(14) When colloid mill is used in the winter season, after parking, it is necessary to unscrew the water plug at the lower part of the pump body to put the medium clean. Prevent frost crack.

(15) If the colloid mill is stopped for a long time, it is necessary to disassemble the pump, dry the water, and put the rotating part and the joint with grease, and keep it properly.