Detailed explanation of the electric heating function of the stirring tank and the reaction kettle

1. Principle: In the interlayer space of the barrel body, an electric heating rod is installed, which changes from voltage to resistance to generate heat, and then conducts heat conduction through the heat-conducting medium inside the interlayer, such as heat-conducting oil, water or other heat-conducting medium. Then the heat is slowly transferred to the material in the barrel.

2. The choice of medium:

The heat transfer oil is generally 320 type heat transfer oil, the temperature of the interlayer can be heated to 300 ℃, and then slowly transferred to the material in the barrel. Theoretically, the material can be heated to 300℃, usually discharged every quarter, filtered and reused.

The water is generally softened pure water with less scale. Since the boiling point of water is 100°C, if water is added inside the interlayer as a medium, the maximum temperature can be heated to 95°C, and it is necessary to check whether the water level decelerates every day.

3. Advantages:

Safety: There are multiple protection devices such as leakage protection, automatic temperature control meter, short circuit protection, undervoltage protection and so on.

Temperature control: flexible temperature control can be achieved through a temperature control meter or PLC. Fully automated, no human intervention required.

4. Disadvantages:

Energy consumption: Generally, the electric heating power is too large, the small one is more than ten kilowatts, and the large one will have hundreds of kilowatts.

Efficiency: The heating rate is very slow, because the interlayer medium needs to be added first, and then transferred to the material. The time required is longer.

Control: If there are multiple temperature controls, the time required is very long.

Single: If the equipment needs cooling function, it needs to discharge the medium and add low-temperature medium of the same medium to achieve the cooling effect. has great limitations.

5. Quality

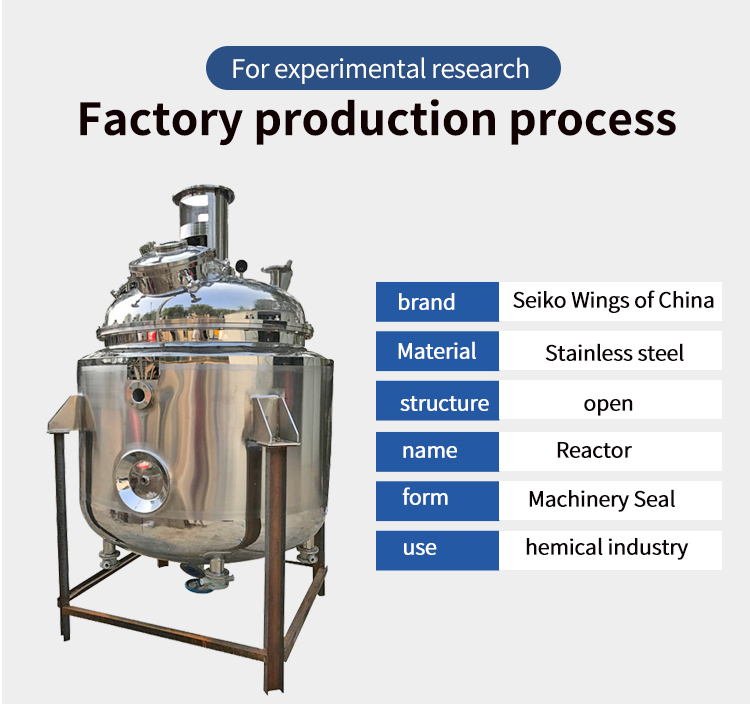

High quality: all stainless steel 304 material, with a fixed piece at the front to prevent mutual contact and burn. Laser marking on the flange. The terminal blocks are polished and beautiful. Gaskets are PTFE high temperature resistant materials.

Ordinary: the resistance tube is made of stainless steel, the threaded tube is made of copper and has a short length, which is easy to leak. Terminals are not ground. Gasket is silicone