Crusher introduction and abnormal handling process

Plastic crusher is mainly used in the crushing and recycling of plastic products, when failure occurs in a short period of time to eliminate, as soon as possible to resume production, it is particularly important. Let's take a look at what to do when common system problems occur.

Abnormal vibration of the crusher

1. The rotor of the motor is different from that of the grinder. The concentricity of the two rotors can be adjusted by moving the position of the motor on the left or right, or by adding pads at the bottom of the motor.

2. Different centers of the rotor of the crusher. The reason is that the two supporting surfaces supporting the rotor shaft are not in the same plane. The bottom of the bearing seat can be padded with copper, or the bottom of the bearing can be added with adjustable wedge iron, to ensure that the two shaft heads are concentric.

3. Part of the crushing chamber vibrates greatly. The reason is that the connection between the coupling and the rotor is different or the quality of the flat hammer inside the rotor is not uniform.

4. The original balance is destroyed. Dynamic balance test must be done after motor repair to ensure overall balance.

5. The anchor bolts of the crusher system are loose or the foundation is not firm. When installing or maintaining the crusher, the anchor bolts should be tightened evenly.

Bearing overheating abnormal sound

1.The two bearing seats are uneven, or the rotor of the motor is different from that of the crusher, will cause the bearing to be impacted by extra load, thus causing the bearing to overheat. In this case, it is necessary to stop the machine immediately to troubleshoot the fault, so as to avoid early bearing damage.

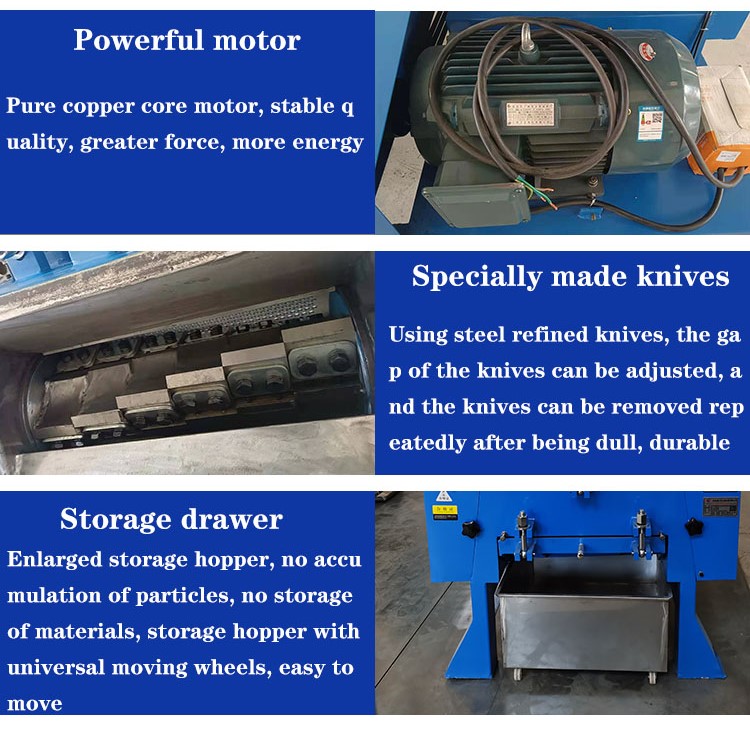

2. Too much or too little lubricating oil in bearings or aging is also the main cause of bearing overheating and damage. Therefore, it is necessary to fill lubricating oil on time and quantitatively according to the requirements of the operation manual. Bearings extend their service life.

3. If the bearing cover and shaft are too tight, the bearing and shaft are too tight or too loose, the bearing will overheat. In the operation of the equipment, it will emit friction sound and obvious swing.

Crusher blockage

1. Feeding speed is too fast, load increases, resulting in blockage. In the process of feeding, we should always pay attention to the large deflection Angle of the ammeter pointer. If it exceeds the rated current, it indicates that the motor is overloaded. Overload for a long time will burn out the motor. In this case, the feed door should be immediately reduced or closed, and the feeding method can also be changed by increasing the feeder to control the feed amount. The feeder has manual and automatic two kinds, the user should choose the appropriate feeder according to the actual situation. Because of the high speed of the crusher, the load is large, and the load fluctuation is strong. Therefore, the current of the mill is generally controlled at about 85% of the rated current.

2. The discharge pipe is not smooth or the feed is blocked too fast, which will block the air outlet of the crusher; Improper matching with conveying equipment will cause the discharge pipe wind weakened or no wind after plugging. After finding out the fault, it is necessary to clear the mismatched conveying equipment with the change of feeding port and adjust the feeding amount to make the equipment run normally.

3. Hammer fragment, aging, screen hole closed, broken, crushed material water content is too high will make the crusher blocked. The broken and severely aged hammer should be updated regularly to keep the mill in good working condition, and check the screen regularly. The moisture content of the crushed material should be less than 14%, which can improve the production efficiency, and make the mill not blocked, and enhance the reliability of the mill.

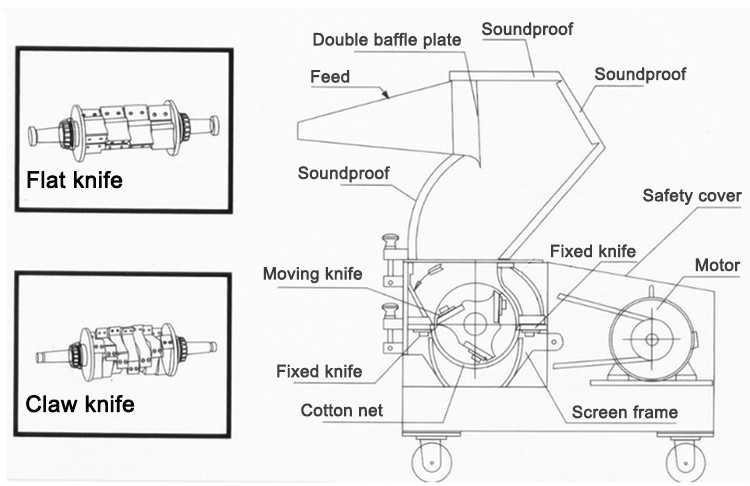

Because there are many kinds of plastic, the things crushed by plastic are more regular granular, but the raw materials of each different plastic composition must be plastic crushers with different tools. Among them, maintenance is also more troublesome. In THE ABS plastic crusher, the tool used is relatively thick and atmospheric, so is the flange. All steel welding base, strong and durable. Thick spindle, high machining accuracy, smooth operation, long service life. Suitable for crushing thick material, hard material block, material and other plastic objects.

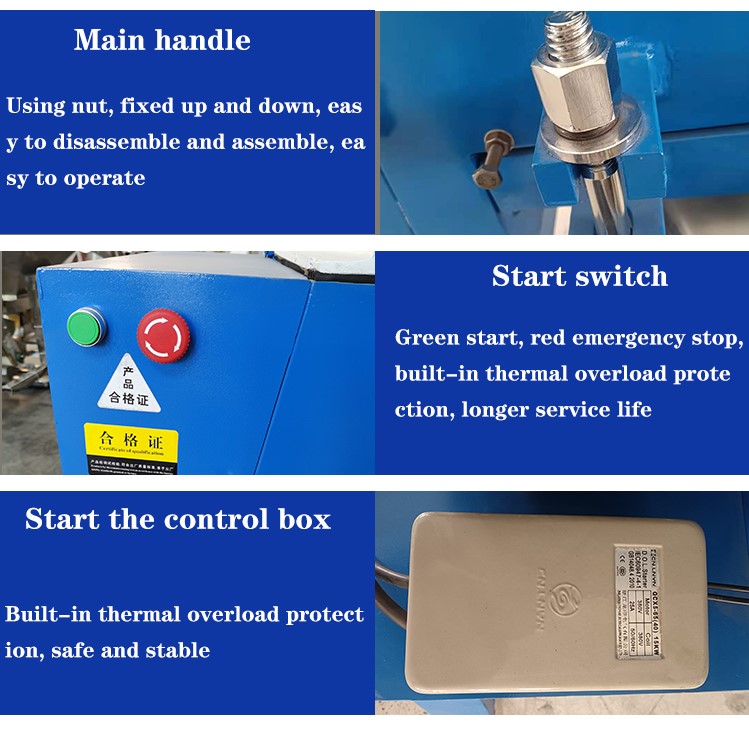

I. The grinder and power unit should be firmly installed. If the crusher is fixed for a long time, it should be fixed on the cement foundation; If the mill is mobile operation, the unit should be installed on the frame made of Angle iron, and ensure that the power machine (diesel engine or motor) and the belt pulley groove of the mill are in the same rotary plane.

Two, after the installation of the crusher to check the fastener fastening situation, if loose to tighten. Also check whether the belt tightness is appropriate.

Three, the crusher should be idled for 2~3min after starting, and then feeding after no abnormal phenomenon.

Four, do not casually replace the pulley, in order to prevent the crushing chamber explosion caused by too high speed, or too low speed affect the working efficiency of the crusher.

5. Before the crusher starts, rotate the rotor by hand to check whether the tooth claw, hammer and rotor operate flexibly and reliably, whether there is collision in the shell, whether the rotating direction of the rotor is consistent with the direction indicated by the arrow of the machine, and whether the lubrication of the power machine and the crusher is good.

6. Pay attention to the operation of the crusher at any time in the work, and the feeding should be uniform to prevent blocking and stuffy cars and not overload work for a long time. If it is found that there is vibration, noise, bearing and body temperature is too high, spraying materials and other phenomena, it should be stopped immediately for inspection, troubleshooting before continuing to work.