-

10-06 2024

Today we introduce a high shear vacuum reactor

Stainless steel reaction vessels are made of stainless steel, mostly made of 304 or 316L stainless steel, meeting production standards. When mixing materials, frame mixing is mainly used to stir and disperse the materials evenly in a short period of time. At the same time, customers can choose different kettle, frame, anchor, and slurry types to mix the items, ensuring that the products are fully and evenly dispersed.

-

09-04 2024

Today, let's talk about the liquid heating mixing reactor

Stainless steel reaction vessels have the characteristics of rapid heating, high temperature resistance, corrosion resistance, hygiene, no environmental pollution, no need for boiler automatic heating, and convenient use. They are widely used in petroleum, chemical, rubber, dyes, food, and other processes such as vulcanization, nitrification, hydrogenation, alkylation, polymerization, and condensation.

-

08-30 2024

Today, let me introduce how to choose a mixing tank and a reaction vessel

Reaction vessels, also known as stirred tanks, are widely used in industries such as coatings, building materials, chemicals, pigments, resins, food, and scientific research. This device can be made of materials such as carbon steel and stainless steel according to the process requirements of the user's product, and equipped with heating and cooling devices to meet different process and production needs. The heating forms include jacket electric heating and coil heating. This equipment has a reasonable structural design, advanced technology, durability, and is characterized by simple operation and easy use. It is an ideal chemical equipment with low investment, fast production, and high returns.

-

06-21 2024

Today we will introduce the complete set of grinding and emulsification equipment

Stainless steel high-speed grinding colloid mill combined with stainless steel low-speed stirring high-speed emulsification reaction kettle is suitable for food and juice manufacturers. Firstly, the material is ground by a grinder and mixed and emulsified into the reaction kettle through a centrifugal pump or rotary pump. Finally, it is discharged through the bottom discharge port.

-

06-03 2024

Today, let's talk about a liquid vacuum reactor

Reactors are widely used in industries such as coatings, building materials, pigments, resins, food, and scientific research. Suitable for mixing and stirring different materials, such as shampoo, shower gel, cosmetic water emulsion, adhesive, ink, paint,etc. It can also be used to mix, dissolve, and evenly mix and stir according to customer requirements. It can also be made into a physical equipment with functions such as heating, homogeneous emulsification, temperature control, and cooling according to customer requirements.

-

12-11 2023

How to choose a suitable mixing tank or reaction kettle for a daily chemical factory?

The reaction kettle is composed of a kettle body, kettle cover, jacket, agitator, transmission device, shaft seal device, support, etc. The mixing forms generally include anchor type, paddle type, turbine type, propulsion type, or frame type. When the height to diameter ratio of the mixing device is large, multiple layers of mixing blades can be used, and can also be selected according to the user's requirements.

-

11-21 2023

Working principle of vacuum reactor

The heating methods of electric heating reaction kettle include electric heating, hot water heating, thermal oil circulation heating, far-infrared heating, external (internal) coil heating, etc. The cooling methods include jacket cooling, internal coil cooling, and stirring blades.

-

09-14 2023

Homogeneous emulsification tank reactor for laboratory use

-

08-12 2023

Double layer stainless steel electric heating reactor ready for shipment to the Philippines

-

06-21 2023

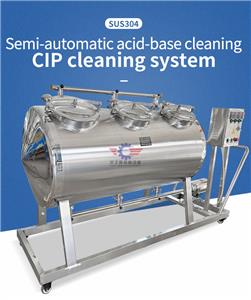

CIP clean tank Acid and alkali cleaning of reactor mixing tank

CIP cleaning tank is specially designed for acid and alkali cleaning of reaction kettle and mixing tank of chemical plant, food factory, pharmaceutical factory and other enterprises.